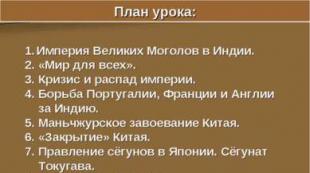

Section classification scheme. Images - views, sections, sections. Basic provisions and definitions

An image of an object mentally dissected by one or more planes is called with a cut. Mental dissection of an object relates only to this cut and does not entail changes in other images of the same object. The section shows what is obtained in the secant plane and what is located behind it.

Sections are used to depict the internal surfaces of an object in order to avoid a large number of dashed lines, which can overlap each other if the internal structure of the object is complex and make the drawing difficult to read.

To make a cut, you need to: mentally draw a secant plane in the desired place on the object (Fig. 173, A); mentally discard part of the object located between the observer and the cutting plane (Fig. 173, b), project the remaining part of the object onto the corresponding projection plane, make the image either in place of the corresponding type, or on the free field of the drawing (Fig. 173, c); shade a flat figure lying in a secant plane; If necessary, give a designation of the section.

Depending on the number of cutting planes, cuts are divided into simple - with one cutting plane, complex - with several cutting planes.

Depending on the position of the cutting plane relative to the horizontal projection plane, the sections are divided into:

horizontal - the cutting plane is parallel to the horizontal plane of projections;

vertical - the cutting plane is perpendicular to the horizontal plane of projections;

inclined - the secant plane makes an angle with the horizontal plane of projections that is different from a right angle.

A vertical section is called frontal if the cutting plane is parallel to the frontal plane of projections, and profile if the cutting plane is parallel to the profile plane of projections.

Complex cuts can be stepped if the cutting planes are parallel to each other, and broken if the cutting planes intersect with each other.

The cuts are called longitudinal if the cutting planes are directed along the length or height of the object, or transverse if the cutting planes are directed perpendicular to the length or height of the object.

Local cuts serve to reveal the internal structure of an object in a separate limited place. The local section is highlighted in the view by a solid wavy thin line.

The rules provide for the designation of cuts.

Rice. 174

The position of the cutting plane is indicated by an open section line. The starting and ending strokes of the section line should not intersect the contour of the corresponding image. On the initial and final strokes you need to put arrows indicating the direction of view (Fig. 174). Arrows should be applied at a distance of 2...3 mm from the outer end of the stroke. In case of a complex section, strokes of an open section line are also drawn at the bends of the section line.

Near the arrows indicating the direction of view from the outside of the angle formed by the arrow and the stroke of the section line, capital letters of the Russian alphabet are written on a horizontal line (Fig. 174). Letter designations are assigned in alphabetical order without repetitions and without gaps, with the exception of letters I, O, X, b, s, b.

The cut itself must be marked with an inscription like “A - A” (always with two letters, separated by a dash).

If the secant plane coincides with the plane of symmetry of the object, and the section is made in place of the corresponding view in the projection connection and is not divided by any other image, then for horizontal, vertical and profile sections it is not necessary to mark the position of the secant plane and the section does not need to be accompanied by an inscription. In Fig. 173 frontal section is not marked.

Simple oblique cuts and complex cuts are always designated.

Let's look at typical examples of constructing and designating sections in drawings.

In Fig. 175 a horizontal section “A - A” is made at the top view. A flat figure lying in a secant plane - a section figure - is shaded, and the visible surfaces located

Rice. 176

below the cutting plane, are limited by contour lines and are not shaded.

In Fig. 176, a profile section is made in place of the view on the left in projection connection with the main view. The cutting plane is a profile plane of symmetry of the object, so the cut is not indicated.

In Fig. 177, a vertical section “A - A” is made, obtained by a secant plane that is not parallel to either the frontal or profile planes of projections. Such sections can be constructed in accordance with the direction indicated by the arrows (Fig. 177), or placed in any convenient place in the drawing, as well as rotated to a position corresponding to that accepted for a given object in the main image. In this case, the sign O is added to the cut designation.

The oblique section is made in Fig. 178. It can be drawn in

projection connection in accordance with the direction indicated by the arrows (Fig. 178, A), or place it anywhere in the drawing (Fig. 178, b).

In the same figure, in the main view, a local section is made showing through cylindrical holes at the base of the part.

In Fig. 179, in place of the main view, a complex frontal stepped section is drawn, made by three frontal parallel planes. When making a step cut, all parallel cutting planes are mentally combined into one, i.e., a complex cut is designed as a simple one. On a complex section, the transition from one cutting plane to another is not reflected.

When constructing broken sections (Fig. 180), one cutting plane is placed parallel to any main projection plane, and the second cutting plane is rotated until it aligns with

first. Together with the secant plane, the section figure located in it is rotated and the cut is made in the rotated position of the section figure.

The connection of part of the view with part of the section in one image of the object according to GOST 2.305-68 is allowed. In this case, the boundary between the view and the section is a solid wavy line or a thin line with a break (Fig. 181).

If half of the view and half of the section are connected, each of which is a symmetrical figure, then the line dividing them is the axis of symmetry. In Fig. 182 there are four images of the part, and in each of them half of the view is combined with half of the corresponding section. In the main view and the left view, the section is placed to the right of the vertical axis of symmetry, and in the top and bottom views - to the right of the vertical or below the horizontal axis of symmetry.

If the contour line of an object coincides with the axis of symmetry (Fig. 183), then the boundary between the view and the section is indicated by a wavy line, which is drawn so as to preserve the image of the edge.

Hatching of a sectional figure included in the section must be carried out in accordance with GOST 2.306-68. Non-ferrous, ferrous metals and their alloys are indicated in cross-section by hatching with solid thin lines with a thickness of S/3 before S/2, which are drawn parallel to each other at an angle of 45° to the lines of the drawing frame (Fig. 184, a). Hatch lines can be drawn slanted to the left or to the right, but in the same direction on all images of the same part. If the hatch lines are drawn at an angle of 45° to the lines of the drawing frame, then the hatch lines can be placed at an angle of 30° or 60° (Fig. 184, b). The distance between parallel hatching lines is chosen in the range from 1 to 10 mm, depending on the hatching area and the need to diversify the hatching.

Non-metallic materials (plastics, rubber, etc.) are indicated by shading with intersecting mutually perpendicular lines (checkered shading), inclined at an angle of 45° to the frame lines (Fig. 184, V).

Let's look at an example. Having completed the frontal section, we will connect half of the profile section with half of the left view of the object specified in Fig. 185, A.

Analyzing this image of the object, we come to the conclusion that the object is a cylinder with two end-to-end prismatic horizontal and two vertical internal

holes, one of which has the surface of a regular hexagonal prism, and the second has a cylindrical surface. The lower prismatic hole intersects the surface of the outer and inner cylinder, and the upper tetrahedral prismatic hole intersects the outer surface of the cylinder and the inner surface of the hexagonal prismatic hole.

The frontal section of an object (Fig. 185, b) is made by the frontal plane of symmetry of the object and is drawn in place of the main view, and the profile section is made by the profile plane of symmetry of the object, so neither one nor the other needs to be designated. The left view and the profile section are symmetrical figures; their halves could be delimited by an axis of symmetry, if not for the image of the edge of the hexagonal hole coinciding with the axial line. Therefore, we separate the part of the view to the left of the profile section with a wavy line, depicting most of the section.

Incision- an image of an object mentally dissected by one or more cutting planes.

The mental dissection of an object determines the convention of the image - the cut, and does not entail changes in other images, because the part of the object located between the observer and the projection plane is removed, conditionally.

The section shows the internal structure of the object, making it possible to avoid the use of dashed lines that make it difficult to read complex elements in the drawing. see also

The cuts are divided according to the following criteria:

1. From the position of the secant planes relative to the projection planes:

Horizontal;

- frontal;

- profile;

- inclined.

Horizontal section obtained using a secant plane parallel to the horizontal projection plane. A horizontal section is usually placed in the place of the top view, but it can also be placed in any free space in the drawing.

Spatial picture of the formation of a horizontal section:

1.

The cutting plane must be parallel to the horizontal projection plane. 2.

The cutting plane should be entered in the place of the model where its internal cavity can be most fully identified when projected onto the horizontal projection plane. 3.

The part of the part above the cutting plane is mentally discarded. 4.

The image on the horizontal projection plane is formed in accordance with the general rules for making cuts.

Vertical section obtained using a secant plane perpendicular to the horizontal projection plane. A vertical section is called frontal if the cutting plane is parallel to the frontal plane, and profile if the cutting plane is parallel to the profile plane of projections.

Spatial picture of the formation of a vertical section:

1.

The cutting plane must be parallel to the frontal projection plane. 2.

The cutting plane should be entered in the place of the model where its internal cavity can be most fully identified when projected onto the frontal projection plane. 3.

The part of the part in front of the cutting plane is mentally discarded. 4.

The image on the frontal plane of projections is formed in accordance with the general rules for making cuts.

2. From the number of cutting planes:

Simple - one cutting plane;

- complex - two or more cutting planes.

Complex cuts are:

Complex stepped;

- complex broken.

3. From the direction of cutting the object:

Longitudinal - along large dimensions of an object;

- transverse - perpendicular to the large dimensions of the object.

4. From the volume of dissection of the object:

Complete, when the entire object is cut through;

- local, if part of the object is cut.

Position cutting plane indicated on the drawing by a section line - an open line.

In a complex cut, strokes are also drawn at the places of transition of one secant to another (in a stepped cut) and the intersection of secants with each other (in a broken line).

Arrows are placed on the initial and final strokes, indicating the direction of view (projection). Arrows should be applied at a distance of 2-3 mm from the outer ends of the strokes.

The starting and ending strokes must not intersect the outline of the corresponding image.

At the beginning and end of the section line, and, if necessary, at the places of transitions and intersections of cutting planes, the same capital letter of the Russian alphabet is placed, and the letter is always placed horizontally and on the outside of the arrow.

The font size for these letters is taken 1-2 sizes larger than the font size for drawing sizes.

The same letters are placed above the cut and are not underlined. The appropriate cuts are made in a similar way after the process of drawing dimensions on the drawing.

Cases of cuts.

When making simple horizontal, frontal, profile sections in cases where the cutting plane coincides with the plane of symmetry of the object as a whole, and the corresponding images are located on the same sheet in direct projection connection and are not separated by any other image, then the position of the cutting plane they are not marked and the incision is not accompanied by an inscription.

When making cuts made by one cutting plane, but having the opposite direction of projection, it is recommended to use one section line, and the arrows are directed according to the selected projection directions and are marked with different capital letters of the Russian alphabet.

If a local cut is made on a part of an object representing a body of revolution, then such a cut can be separated from the view by a thin dash-dotted line, which is the axis of this part of the object.

It is allowed to connect part of the view and part of the section, separating them with a solid wavy line or a solid thin line with breaks (like a local section). In this case, it does not matter which of the images (view or section) will occupy a larger or smaller part of the projection. Such a cut is not indicated.

If half of the view and half of the section are connected, each of which is a symmetrical figure, then the dividing line is the axis of symmetry. In this case, half of the incision is usually placed on the right with a vertical and below with a horizontal axis of symmetry (dash-dotted thin line).

In this case, the statement that one quarter of the object was cut out here with two supposedly secant planes is not true. Drawing dashed lines for invisible elements on half of the view may be unnecessary.

If, with a possible combination of half the view and half the section, a solid main line coincides with the axis of symmetry, then it must be shown, but they separate the view and the section with a solid wavy line, showing more of the view if the solid main line is external or more of the section if the solid line is internal .

Connecting half a view with half a section is possible not only for simple sections, but for complex ones, when the independent images (view and section) are symmetrical.

It is allowed to use a cylindrical surface and a cut as a secant deploy. In this case, the “expanded” sign is placed above the cut.

It is allowed to combine a quarter of a view and a quarter of three sections (and other combinations), provided that each of these images is individually symmetrical.

At complex broken cuts The cutting planes are conventionally rotated until they are aligned into one plane parallel to the projection plane. Such a section may be placed in place of the corresponding main view. Complex polygonal cuts can be made using more than two cutting planes. When rotating the secant plane, the elements of the object located behind it are drawn as they are projected onto the corresponding plane with which the alignment is made. The rotation direction may not be the same as the viewing (projection) direction.

Broken cut is formed when a part is cut by planes intersecting at an angle greater than 90. As a rule, one of the cutting planes is placed parallel to one of the main projection planes. When constructing an image, the inclined plane is aligned (rotated) to a plane parallel to the projection plane. Next, a broken section is constructed by analogy with a simple one, while the line of intersection of the cutting planes is not shown on the section. It is allowed to place a broken cut in place of the corresponding type, i.e. on the projection plane to which one of the cutting planes is parallel.

Theoretical material giving the concepts of types, sections and sections is discussed in GOST 2305-81. Before you start making drawings, you need to understand the terms and definitions given in GOST 2305-81.

Projection is an image of an object on a projection plane with all visible and invisible details.

View is an image of the visible part of the surface of an object. Species are divided into three groups: main, additional, local.

The main views are the views of the object obtained by projecting into place the main projection planes established by GOST 2305-81 (Fig. 11).

Figure 11

There are six main types in total:

1) front view (main). Projection onto p 2 ;

2) top view. Projection onto p 1 ;

3) left view. Projection onto p 3 ;

4) right view. Projection onto p 3 ;

5) bottom view. Projection onto p 2 ;

6) rear view. Projection onto p 1.

In practice, the first three types are most often used, the remaining three - if necessary. It is quite rare to find a part that requires all six types.

When drawing a part, it is important to select the main view (front view). When choosing the main view, it is necessary to take into account that it should give the most complete picture of the shape of the model. The top and left views should be located in projection connection with the front view, but there is no need to draw projection axes, connection lines and the complex drawing constant on the drawing.

An additional view is an image on a plane that is not parallel to any of the main planes, but perpendicular to one of them (Fig. 12a). In the drawing, on the projection, detail the plane to which the additional view is perpendicular, the direction of view is marked with an arrow, and a capital letter of the Russian alphabet is placed next to the arrow. The additional view itself must have a title with the corresponding letter, for example: “ViewA”.

Figure 12

A local view is an image of a limited part of an object (Fig. 12b). Part of the object is limited by a thin wavy line.

In addition to depicting the visible part of an object, there is often a need to show the inside of the object. For this purpose, cuts and sections are made in the drawings.

A cut is the mental dissection of an object with one or more planes. The section shows what is obtained in the secant plane and what is located behind it. The cuts are divided into simple and complex.

Simple cuts - the cutting plane is parallel to some main projection plane. The incision can be horizontal, frontal, profile, vertical and transverse.

If the part is symmetrical, then half the view is done with half a simple cut. This cut is called combined- combination of part of the view and part of the section (Fig. 13 a, b).

When combined, the dividing line is the axis of symmetry (i.e., the dash-dotted line). If in the image of an object the axis of symmetry coincides with the edge, then to reveal the design of the part, a line is drawn a little more or a little less than half of the section (depending on where the edge is located: in the view or in the section). In this case, the boundary between the view and the section is a thin wavy line (Fig. 13 b).

A local cut is a cut made on a limited part of the part (Fig. 13 c). Limited by a thin wavy line.

Figure 13

Complex cuts - the part is cut through several planes. There are two types of complex cuts: broken and stepped.

Broken section - there are usually two cutting planes, and these planes intersect at an angle to each other (Fig. 14 a).

A feature of making a broken cut is the combination of secant planes. Due to this feature, the view on which the broken cut is made does not always coincide with the visible contour; sometimes the visible contour is distorted.

In one of the views, a broken section line is indicated - the place where the cutting planes exit and the place where they intersect. An open line is used to indicate a broken cut line. Arrows are added to the strokes of this line to indicate the direction of view and a letter designation of the cut. The view in which the broken section is made is titled with the letters of an open line (for example, “A-A”). The intersection of the planes in the section does not provide any additional line or boundary.

Figure 14

Stepped section - there are at least two cutting planes, and they are located parallel to each other (Fig. 14 b). Just as when making a broken cut, the cut line is indicated. The place where the cut transitions from one plane to another appears in the drawing in the form of steps (hence the name of the cut). In the section, the place of transition from one plane to another is not indicated in any way. Just like a broken cut, a step cut should have a title in the form of a letter designation of the cut line (for example, “B-B”).

A section is an image of a figure obtained by mentally dissecting an object with one or more planes. The section shows only what falls within the cutting plane (Fig. 15). The section can be superimposed - if the image of the object is combined with the view; or remote - if the section image is moved outside the part view. When performing an extension section, you must indicate the section line, and the section itself must have a title.

Figure 15

GOST 2305-81 contains a number of features and conventions that must be taken into account when making cuts and sections.

If the cutting plane is directed along a thin wall or stiffener, then the wall cut by this plane appears unshaded and is limited by a solid line of the visible contour. If there is a local drilling or recess in such elements of a part, then a local cut is made to open it (Fig. 16).

Figure 16

A cross section of a thin wall is depicted according to general rules, i.e. the part that falls into the cutting plane is shaded.

If the cutting plane passes through the axis of the surface of revolution that bounds the hole or recess, then the outline of the hole or recess in the section is shown in full. If the cutting plane passes through a non-circular hole and the section turns out to consist of separate parts, not a section, but a cut should be used.

GOST 2.305-2008

Group T52

INTERSTATE STANDARD

Unified system of design documentation

IMAGES - VIEWS, SECTIONS, SECTIONS

Unified system for design documentation. Images - appearance, sections, profiles

ISS 01.100.01

OKSTU 0002

Date of introduction 2009-07-01

Preface

The goals, basic principles and basic procedure for carrying out work on interstate standardization are established by GOST 1.0-92 "Interstate standardization system. Basic provisions" and GOST 1.2-97 "Interstate standardization system. Interstate standards, rules and recommendations for interstate standardization. Procedure for development, adoption, application, renewal and cancellation"

Standard information

1 DEVELOPED by the Federal State Unitary Enterprise All-Russian Research Institute of Standardization and Certification in Mechanical Engineering (VNIINMASH), the Autonomous Non-Profit Organization Scientific Research Center for CALS Technologies "Applied Logistics" (ANO NIC CALS Technologies "Applied Logistics")

2 INTRODUCED by the Federal Agency for Technical Regulation and Metrology

3 ADOPTED by the Interstate Council for Standardization, Metrology and Certification (Protocol No. 33 of August 28, 2008)

The following voted for adoption:

Short name of the country according to MK (ISO 3166) 004-97 | Abbreviated name of the national standardization body |

|

Azerbaijan | Azstandard |

|

Armenia | Ministry of Trade and Economic Development |

|

Belarus | State Standard of the Republic of Belarus |

|

Kazakhstan | Gosstandart of the Republic of Kazakhstan |

|

Kyrgyzstan | Kyrgyzstandard |

|

Moldova | Moldova-Standard |

|

Russian Federation | Federal Agency for Technical Regulation and Metrology |

|

Tajikistan | Tajikstandard |

|

Turkmenistan | Main State Service "Turkmenstandartlary" |

|

Ukraine | Gostpotrebstandart of Ukraine |

4 By Order of the Federal Agency for Technical Regulation and Metrology dated December 25, 2008 N 703-st, the interstate standard GOST 2.305-2008 was put into effect as a national standard of the Russian Federation on July 1, 2009.

5 INSTEAD GOST 2.305-68

Information on the entry into force (termination) of this standard is published in the “National Standards” index.

Information about changes to this standard is published in the “National Standards” index, and the text of the changes is published in the “National Standards” information indexes. In case of revision or cancellation of this standard, the relevant information will be published in the information index "National Standards"

An amendment has been made, published in IUS No. 12, 2018

Amendment made by database manufacturer

1 area of use

1 area of use

This standard establishes the rules for depicting objects (products, structures and their components) on drawings (electronic models) of all industries and construction.

2 Normative references

This standard uses references to the following interstate standards:

GOST 2.052-2006 Unified system of design documentation. Electronic model of the product. General provisions

GOST 2.102-68 Unified system of design documentation. Types and completeness of design documents

GOST 2.103-68 Unified system of design documentation. Development stages

GOST 2.104-2006 Unified system of design documentation. Basic inscriptions

GOST 2.109-73 Unified system of design documentation. Basic requirements for drawings

GOST 2.302-68 Unified system of design documentation. Scale

GOST 2.317-69 Unified system of design documentation. Axonometric projections

Note - When using this standard, it is advisable to check the validity of reference standards on the territory of the state according to the corresponding index of standards compiled as of January 1 of the current year, and according to the corresponding information indexes published in the current year. If the reference standard is replaced (changed), then when using this standard you should be guided by the replacing (changed) standard. If the reference standard is canceled without replacement, then the provision in which a reference is made to it is applied in the part that does not affect this reference.

3 Terms and definitions

The following terms with corresponding definitions are used in this standard:

3.1 vertical section: A section made by a cutting plane perpendicular to the horizontal projection plane.

(Amendment. IUS N 12-2018).

3.2 type of item (type): An orthogonal projection of the visible part of the surface of an object facing the observer, located between it and the projection plane.

3.3 extended section: A section located in a drawing outside the contour of the image of an object or in a gap between parts of one image.

3.4 callout: An additional, usually enlarged, separate image of part of an object.

3.5 main view of the item (main view): The main view of an object on the frontal projection plane, which gives the most complete idea of the shape and size of the object, relative to which the other main views are located.

3.6 horizontal section: A section made by a secant plane parallel to the horizontal projection plane.

(Amendment. IUS N 12-2018).

3.7 additional type of item (additional type): An image of an object on a plane not parallel to any of the main projection planes, used for an undistorted image of the surface if it cannot be obtained in the main view.

3.8 broken cut: A complex cut made by intersecting planes.

3.9 local type of item (local view): Image of a separate limited area of the surface of an object.

3.10 local cut: A cut made with a cutting plane only in a separate, limited area of the object.

3.11 oblique cut: A section made by a secant plane that makes an angle other than a right angle with the horizontal plane of projections.

3.12 superimposed section: A section located directly on the image of an object along the trace of the cutting plane.

3.13 orthogonal (rectangular) projection: A parallel projection of an object or part of it onto a plane perpendicular to the direction of the projecting rays, representing one of the faces of a hollow cube, combined with the drawing, within which the object is mentally placed.

3.14 main type of item (main type): The type of object that is obtained by combining the object and its image on one of the faces of the hollow cube, inside which the object is mentally placed, with the plane of the drawing.

Note - The main type of an object can refer to the object as a whole, its section or section.

3.15 parallel projection: An image of an object or part of it, obtained by projecting them with an imaginary parallel beam of rays onto a plane.

3.16 cross section: A cut made by a cutting plane directed perpendicular to the length or height of the object.

3.17 lengthwise cut: A cut made by a cutting plane directed along the length or height of an object.

3.18 simple cut: A section made by one cutting plane.

3.19 profile section: A vertical section made by a secant plane parallel to the profile plane of projections.

(Amendment. IUS N 12-2018).

3.20 section of an object (section): An orthogonal projection of an object mentally dissected in whole or in part by one or more planes to reveal its invisible surfaces.

3.21 section of an object (section): An orthogonal projection of a figure resulting in one or more secant planes or surfaces when mentally dissecting the projected object.

Note - If necessary, it is possible to use a cylindrical surface as a secant, which can be developed onto the drawing plane.

3.22 complex cut: A cut made by two or more cutting planes.

3.23 step cut: A complex section made by parallel cutting planes.

3.24 frontal section: A vertical section made by a cutting plane parallel to the frontal plane of projections.

(Amendment. IUS N 12-2018).

4 Basic provisions

4.1 General requirements for the content of the drawing - in accordance with GOST 2.109, electronic model of the product - in accordance with GOST 2.052.

4.2 Images of objects in the drawing should be performed using the rectangular projection method. In this case, the object is assumed to be located between the observer and the corresponding projection plane (see Figure 1).

Picture 1

4.3 The six faces of the cube are taken as the main projection planes; the faces are combined with the plane, as shown in Figure 2. Face 6 can be placed next to face 4.

Figure 2

4.4 The image on the frontal plane of projections is taken as the main one in the drawing. The object is positioned relative to the frontal projection plane so that the image on it gives the most complete idea of the shape and size of the object.

4.5 Depending on the content, images are divided into types, sections, sections.

The scale of images located in direct projection connection with each other on the main projection planes is taken as the scale of the document and is recorded in the corresponding details of the main inscription (GOST 2.104). All other images made in the drawing on a different scale must have instructions about it.

4.6 To reduce the number of images, it is allowed to show the necessary invisible parts of the surface of an object in views using dashed lines (see Figure 3).

Figure 3

4.7 When making a cut, the mental dissection of an object applies only to this cut and does not entail changes in other images of the same object. The section shows what is obtained in the secant plane and what is located behind it (see Figure 4). It is allowed to depict not everything that is located behind the cutting plane, if this is not required to understand the design of the object (see Figure 5).

Figure 4

Figure 5

4.8 The section shows only what is obtained directly in the cutting plane (see Figure 6).

Figure 6

It is allowed to use a cylindrical surface as a secant, which is then developed into a plane (see Figure 7).

Figure 7

4.9 The number of images (types, sections, sections) should be the smallest, but providing a complete picture of the subject when using the symbols, signs and inscriptions established in the relevant standards.

5 Types

5.1 The following names of views obtained on the main projection planes have been established (main views, Figure 2):

1 - front view (main view);

2 - top view;

3 - left view;

4 - right view;

5 - bottom view;

6 - rear view.

When creating graphic documents in the form of electronic models (GOST 2.052), saved views should be used to obtain the corresponding images.

In construction drawings, where necessary, it is allowed to assign special names to the corresponding views, for example “facade”.

Names of views should not be inscribed on the drawings, except as provided in 5.2. In construction drawings it is allowed to inscribe the name of the type and assign it an alphabetic, numerical or other designation.

5.2 If the views from above, left, right, below, behind are not in direct projection connection with the main image (view or section shown on the frontal projection plane), then the direction of projection should be indicated by an arrow next to the corresponding image. The same capital letter should be placed above the arrow and above the resulting image (view) (see Figure 8).

Figure 8

Drawings are designed in the same way if the listed views are separated from the main image by other images or are not located on the same sheet with it.

When there is no image that can show the direction of view, the name of the species is inscribed.

In construction drawings, it is allowed to indicate the direction of view with two arrows (similar to indicating the position of cutting planes in sections).

In construction drawings, regardless of the relative position of the views, it is allowed to inscribe the name and designation of the view without indicating the direction of view with an arrow, if the direction of view is determined by the name or designation of the view.

5.3 If it is necessary to obtain a visual image of an object in the drawing, axonometric projections are used in accordance with GOST 2.317.

5.4 If any part of the object in the drawing cannot be shown in the views listed in 5.1 without distorting the shape and size, then additional views are used, obtained on planes not parallel to the main projection planes (see Figures 9-11). In electronic models, additional types are not used.

Figure 9

Figure 10

Figure 11

5.5 An additional view must be marked on the drawing with a capital letter (see Figures 9, 10), and the image of an object associated with the additional view must have an arrow indicating the direction of view, with a corresponding letter designation (for example, arrow B, Figures 9, 10).

When an additional view is located in direct projection connection with the corresponding image, the arrow and view designation are not applied (see Figure 11).

5.6 Additional views are located as shown in Figures 9-11. The arrangement of additional views according to Figures 9 and 11 is preferable.

An additional view can be rotated, but with, as a rule, maintaining the position adopted for a given item in the main image, and the designation of the view must be supplemented with a conventional graphic designation. If necessary, indicate the angle of rotation (see Figure 12).

Figure 12

Several identical additional types related to one subject are designated by one letter and one type is drawn. If, in this case, parts of the object associated with an additional type are located at different angles, then a conventional graphic designation is not added to the type designation.

5.7 Local view (view G, Figure 8; view D, Figure 13) can be limited by the break line, if possible in the smallest size (view D, Figure 13), or not limited (view G, Figure 13). The detail view should be marked on the drawing like the supplementary view.

Figure 13

5.8 The ratio of the sizes of the arrows indicating the direction of view must correspond to those shown in Figure 14.

Figure 14

6 Cuts

6.1 Depending on the position of the cutting plane relative to the horizontal plane of projections, sections are divided into:

- horizontal (for example, a section A-A, Figure 13; incision B-B, Figure 15).

Figure 15

In construction drawings, horizontal sections may be given other names, such as “plan”;

- vertical (for example, a section in place of the main view, Figure 13; sections A-A, V-V, Y-Y, Figure 15);

- inclined (for example, section B-B, Figure 8).

Depending on the number of cutting planes, sections are divided into:

- simple (see Figures 4, 5);

- complex (for example, a cut A-A, Figure 8; incision B-B, Figure 15).

6.2 A vertical section can be frontal (for example, section, Figure 5, section A-A, Figure 16), and profile (for example, section B-B, Figure 13).

6.3 Complex cuts can be stepped (for example, a stepped horizontal cut B-B, Figure 15; stepped frontal section A-A, Figure 16) and broken lines (for example, cuts A-A, Figures 8 and 15).

Figure 16

6.4 Sections can be longitudinal (see Figure 17) and transverse if the cutting planes are directed perpendicular to the length or height of the object (for example, cuts A-A And B-B, Figure 18).

Figure 17

Figure 18

6.5 The position of the cutting plane is indicated in the drawing by a section line. An open line should be used for the section line. In case of a complex cut, strokes are also made at the intersection of the cutting planes. Arrows should be placed on the initial and final strokes indicating the direction of view (see Figures 8-10, 13, 15); arrows should be applied at a distance of 2-3 mm from the end of the stroke.

The starting and ending strokes must not intersect the outline of the corresponding image.

In cases such as those indicated in Figure 18, arrows indicating the direction of view are drawn on the same line.

6.6 At the beginning and end of the section line, and, if necessary, at the intersection of cutting planes, the same capital letter of the Russian alphabet is placed. The letters are placed near the arrows indicating the direction of view, and at the intersection points from the outer corner.

The incision must be marked by type "A-A"(always two letters separated by a dash).

In construction drawings, near the section line, it is allowed to use numbers instead of letters, as well as write the name of the section (plan) with an alphanumeric or other designation assigned to it.

6.7 When the cutting plane coincides with the plane of symmetry of the object as a whole, and the corresponding images are located on the same sheet in direct projection connection and are not separated by any other images, for horizontal, frontal and profile sections the position of the cutting plane and the cut are not marked with an inscription are not accompanied (for example, a section at the site of the main species, Figure 13).

6.8 Frontal and profile sections, as a rule, are given a position corresponding to that accepted for a given item in the main image of the drawing (see Figure 12).

6.9 Horizontal, frontal and profile sections can be located in place of the corresponding main views (see Figure 13).

6.10 A vertical section, when the cutting plane is not parallel to the frontal or profile planes of projections, as well as an inclined section must be constructed and located in accordance with the direction indicated by the arrows on the section line.

It is allowed to place such sections anywhere in the drawing (section V-V, Figure 8), as well as with rotation to the position corresponding to that accepted for this object in the main image. In the latter case, a conventional graphic designation must be added to the inscription (section Y-Y, Figure 15).

6.11 For broken cuts, the cutting planes are conditionally rotated until they are aligned into one plane, and the direction of rotation may not coincide with the direction of view (see Figure 19).

Figure 19

If the combined planes turn out to be parallel to one of the main projection planes, then a broken section can be placed in place of the corresponding type (sections A-A, Figures 8, 15). When rotating the secant plane, the elements of the object located behind it are drawn as they are projected onto the corresponding plane with which the alignment is made (see Figure 20).

Figure 20

6.12 A local section is highlighted in the view by a solid wavy line (see Figure 21) or a solid thin line with a break (see Figure 22). These lines must not coincide with any other lines in the image.

Figure 21

Figure 22

6.13 Part of the view and part of the corresponding section can be connected by separating them with a solid wavy line or a solid thin line with a break (see Figures 23-25). If at the same time half of the view and half of the section are connected, each of which is a symmetrical figure, then the dividing line is the axis of symmetry (see Figure 26). It is also possible to separate the section and view by a thin dash-dotted line (see Figure 27), coinciding with the trace of the plane of symmetry not of the entire object, but only of its part, if it is a body of revolution.

Figure 23

Figure 24

Figure 25

Figure 26

Figure 27

6.14 It is allowed to connect a quarter of a view and quarters of three sections: a quarter of a view, a quarter of one section and half of another, etc. provided that each of these images is individually symmetrical.

7 Sections

7.1 Sections not included in the section are divided into:

- taken out (see Figures 6, 28);

- superimposed (see Figures 29-32).

Figure 28

Figure 29

It is allowed to place sections anywhere in the drawing field, as well as with rotation and the addition of a conventional graphic symbol.

Extended sections are preferred and can be located in the gap between parts of the same type (see Figure 30).

Figure 30

In electronic models, only superimposed sections are used (see Figure 31).

Figure 31

7.2 In the drawings, the contour of the extended section, as well as the section included in the section, is depicted with solid main lines, and the contour of the superimposed section is shown with solid thin lines, and the contour of the image at the location of the superimposed section is not interrupted (see Figures 13, 28, 29) .

7.3 The axis of symmetry of an extended or superimposed section (see Figures 6, 29) is indicated by a thin dash-dotted line without letters and arrows, and the section line is not drawn.

In cases similar to those indicated in Figure 30, with a symmetrical cross-sectional figure, the section line is not drawn.

7.4 In all other cases, in the drawings, an open line is used for the section line, indicating the direction of view with arrows and denoted by the same capital letters of the Russian alphabet (in construction drawings - uppercase or lowercase letters of the Russian alphabet or numbers).

In the drawings, the section is accompanied by an inscription according to the type "A-A"(see Figure 28). In construction drawings it is allowed to inscribe the name of the section. On electronic models, the section is not accompanied by an inscription. It is recommended to assign the saved view, which is used to display the section, the same name as the section by type "A-A".

7.5 On electronic models, a visual representation of the cutting plane should be used to indicate the location and direction of view of the section. The contour of the image of the cutting plane is depicted with solid main lines, and the contour of the superimposed section with solid thin lines, and the contour of the image at the location of the superimposed section is not interrupted (see Figures 31, 32). It is allowed to highlight the image of the secant plane in a color different from the color of the image of the object, if the display device of the electronic computer allows this.

Figure 32

In drawings for asymmetrical sections located in a gap (see Figure 33) or superimposed (see Figure 34), the section line is drawn with arrows, but is not marked with letters.

Figure 33

Figure 34

In construction drawings, for symmetrical sections, an open line is used with its designation, but without arrows indicating the direction of view.

7.6 The section in construction and location must correspond to the direction indicated by the arrows (for the drawing - Figure 28, for the electronic model - Figures 31, 32, 35).

To visualize sections on models, it is recommended to use saved views. In this case, all cutting planes used in the model must be uniquely identified, and all sections must be made to the scale of the electronic model.

To indicate the direction of view of the section, visible arrows should be used, as shown in Figures 31, 32. It is allowed to indicate the direction of view of the section, as shown in Figure 35.

Figure 35

The result of the section can be shown either by visualizing the lines defining the intersection of the cutting planes with the object, displayed directly on the model and overlapping its image (see Figure 32), or by removing material from the image of the object model (see Figure 35).

For broken and stepped sections, the cutting planes should be shown connected to each other (see Figure 35).

7.7 For several identical sections related to one object, the section line is designated with one letter and one section is drawn (see Figures 36, 37).

Figure 36

Figure 37

If the cutting planes are directed at different angles (see Figure 38), then the conventional graphic designation is not applied.

Figure 38

When the location of identical sections is precisely determined by the image or dimensions, it is allowed to draw one section line, and indicate the number of sections above the section image.

7.8 Cutting planes are selected so as to obtain normal cross sections (see Figure 39).

Figure 39

7.9 If the cutting plane passes through the axis of the surface of rotation that bounds the hole or recess, then the contour of the hole or recess in the section is shown in full (see Figure 40).

Figure 40

7.10 If the section turns out to consist of separate independent parts, then cuts should be used (see Figure 41).

Figure 41

7.11 Saved views must be associated with the model of the item, and changes to the model must cause corresponding changes in sections in all saved views.

8 Details

8.1 A remote element is used in drawings, as a rule, to place any part of an object that requires graphic and other explanations regarding shape, size and other data.

In electronic models, remote elements are not used.

The detail element may contain details not indicated on the corresponding image, and may differ from it in content (for example, the image may be a view, and the detail element may be a section).

8.2 When using an extension element, the corresponding place is marked on the view, section or section with a closed solid thin line - a circle, an oval, etc. with the designation of a leader element in a capital letter or a combination of a capital letter and an Arabic numeral on the shelf of the leader line. Above the image of the extension element, indicate the designation and scale in which it is made (see Figure 42). Scale values are according to GOST 2.302.

Figure 42

In construction drawings, the extension element in the image can also be marked with a curly or square bracket or not marked graphically. The image from which the element is being taken out, and the extension element, may also have the alphabetic or numerical (Arabic numerals) designation and name assigned to the extension element.

8.3 The remote element is placed as close as possible to the corresponding place on the image of the object.

9 Conventions and simplifications

9.1 The details of the image of the object are established by the developer based on the requirements for the content of the document depending on the stage of development (GOST 2.103) and the type of document (GOST 2.102).

9.2 If the view, section or section is a symmetrical figure, it is allowed to draw half of the image (View B, Figure 13) or slightly more than half of the image, drawing a break line in the latter case (see Figure 25).

9.3 If an object has several identical, evenly spaced elements, then the image of this object shows one or two such elements in full (for example, one or two holes, Figure 15), and the remaining elements are shown in a simplified or conditional manner (see Figure 43).

Figure 43

It is allowed to depict a part of an object (see Figures 44, 45) with appropriate instructions on the number of elements, their location, etc.

Figure 44

Figure 45

9.4 In views and sections, it is allowed to depict in a simplified manner the projections of the lines of intersection of surfaces, if their precise construction is not required. For example, instead of pattern curves, circular arcs and straight lines are drawn (see Figures 46, 47).

Figure 46

Figure 47

9.5 A smooth transition from one surface to another is shown conditionally (see Figures 48-50) or not shown at all (see Figures 51-53).

Figure 48

Figure 49

Figure 50

Figure 51

Figure 52

Figure 53

Simplifications similar to those shown in Figures 54-57 are allowed.

Figure 54

Figure 55

Figure 56

Figure 57

9.6 Parts such as screws, rivets, keys, non-hollow shafts and spindles, connecting rods, handles, etc., are shown uncut in a longitudinal section. The balls are always shown uncut.

As a rule, nuts and washers are shown uncut on assembly drawings.

Elements such as spokes of flywheels, pulleys, gears, thin walls such as stiffeners, etc. are shown unshaded if the cutting plane is directed along the axis or long side of such element.

If such elements of the part have a local drilling, recess, etc., then a local cut is made, as shown in Figures 21, 22.

9.7 Plates, as well as elements of parts (holes, chamfers, grooves, recesses, etc.) with a size (or difference in size) of no more than 2 mm are depicted in the drawing with a deviation from the scale adopted for the entire image in the direction of enlargement.

9.8 A slight taper or slope may be depicted with magnification.

If the slope or taper is not clearly visible, for example, the main view in Figure 56 or the top view in Figure 57, then only one line is drawn on the images, corresponding to the smaller size of the element with the slope or the smaller base of the cone.

9.9 If it is necessary to highlight flat surfaces of an object in the drawing, diagonals are drawn on them with solid thin lines (see Figure 58).

Figure 58

9.10 Objects or elements that have a constant or naturally changing cross-section (shafts, chains, rods, shaped steel, connecting rods, etc.) may be depicted with breaks.

Partial and broken images are limited in one of the following ways:

a) a continuous thin line with a break, which can extend beyond the contour of the image to a length of 2-4 mm. This line may be inclined relative to the contour line (see Figure 59);

Figure 59

b) a solid wavy line connecting the corresponding contour lines (see Figure 60);

Figure 60

c) hatch lines (see Figure 61).

Figure 61

9.11 In the drawings of objects with a continuous mesh, braiding, ornament, relief, knurling, etc. it is allowed to depict these elements partially with possible simplification (see Figure 62).

Figure 62

9.12 To simplify drawings or reduce the number of images, it is allowed:

a) the part of the object located between the observer and the cutting plane should be depicted with a thickened dash-dot line directly on the section (superimposed projection, Figure 63);

Figure 63

b) use complex cuts (see Figure 64);

Figure 64

c) to show holes in the hubs of gear wheels, pulleys, etc., as well as for keyways, instead of a full image of the part, give only the outline of the hole (see Figure 65) or groove (see Figure 55);

Figure 65

d) depict in section the holes located on the round flange when they do not fall into the secant plane (see Figure 15).

9.13 If a top view is not necessary and the drawing is compiled from images on the frontal and profile projection planes, then with a stepped section, the section line and inscriptions related to the section are applied as shown in Figure 66.

Figure 66

9.14 Conventions and simplifications allowed in permanent connections, in drawings of electrical and radio engineering devices, gears, etc. are established by relevant standards.

9.15 The graphic symbol “rotated” must correspond to Figure 67 and “expanded” - Figure 68.

Figure 67

Figure 68

Bibliography

ISO 5456-2:1996 | Technical drawings. Projection methods. Part 2. Representation in orthographic projection |

|

ISO 5456-3:1996 | Technical drawings. Projection methods. Part 3. Axonometric projection |

|

ISO 10303-202:1996 | Production automation systems and their integration. Presentation and exchange of product data. Part 202. Application protocol. Associative drawing |

Revision of the document taking into account

changes and additions prepared

JSC "Kodeks"

Images in the drawings are divided into types, sections, sections in accordance with GOST ohm 2.305 - 68. Images are a graphic expression of an object, made by rectangular projection, on a given scale using the basic rules of conventions and simplifications, and serve to characterize the properties of geometric objects.

9.1. Kinds

View called the image of the visible part of the surface of an object facing the observer.

All product images are projected onto projection planes, which are taken to be the six faces of the cube. The development of these faces on the drawing plane makes it possible to obtain six projections of the object (Fig. 9.1).

Rice. 9.1. The main projection planes of the drawing.

The main view (front view) is located in projection connection with other views (top, bottom, right, left, rear).

If the views are shifted relative to the main view, then they are designated in the drawing as an additional view, type “A” (Fig. 9.2).

In this case, an arrow (5 mm in size) indicates the direction of view of the view of the part with the corresponding letter of the Russian alphabet, as shown in Fig. 9.2.

An additional view is an image obtained on an additional plane that is not parallel to the main projection planes. It can be offset or rotated relative to the main view. This type is designated in the same way as described above and is shown in Fig. 9.2.

Rice. 9.2. Additional types.

If the view is rotated, then you need to add information to its name in the form of a circle with a diameter of 3 - 5 mm and an arrow located on it.

The image of a specific location on the surface of a part is called a detail view and may be limited to a thin break line.

Information about which surfaces are inside the part is conveyed using dashed lines (invisible contour lines). To identify these surfaces, cuts are used.

9.2. Brief classification of cuts

Incision - an image obtained by mentally dissecting a part with one or more secant planes, while on the drawing plane what is included in the secant plane and what is located behind it is depicted.

According to the location of the secant planes relative to the projection planes, the sections are divided into:

1) Horizontal- the secant plane is parallel to the horizontal plane of projections P 1;

2) Vertical

a) the cutting plane is parallel to the frontal plane of projections P 2 (Fig. 9.3)

Rice. 9.3. Frontal section.

b) the cutting plane is parallel to the profile plane of projections P 3 (Fig. 9.4)

Rice. 9.4. Profile section.

3) Oblique- the cutting plane is not parallel to the main projection planes (Fig. 3.5).

Rice. 3.5. Oblique cut.

The cuts are called longitudinal, if the cutting planes are directed along the length or height of the product, and transverse, if the cutting planes are directed perpendicular to them..

According to the number of secant planes mentally dissecting the part, the sections are divided into:

simple, when the section involves one cutting plane,

complex when the cut is made using several cutting planes.

In turn, complex sections are divided into:

A) stepped when the cutting planes are parallel to each other (Fig. 9.6);

Rice. 9.6. Stepped cut.

b) broken, when cutting planes intersect (Fig. 9.7)

Rice. 9.7. Broken cut.

The position of the cutting plane is marked in the drawing with an open section line (GOST 2.303 - 68) thickness from S to 1.5S. Open line strokes should not intersect the outline of the image. Arrows are drawn to the strokes of the open section line, indicating the direction of view (Fig. 9.69.6). Arrows are applied at a distance of 2 - 3 mm from the outer stroke of the section line. Near the arrows, on the outside of the ends of the strokes of the section line, an inscription is made in one capital letter of the Russian alphabet. The letter height should be one or two font numbers larger than the size numbers. Above the image of the section with the designated cutting plane, an inscription of type A - A is made (Fig. 9.7). The inscription is not underlined.

The designation of cutting planes is introduced for simple cuts, if the cutting plane does not pass along the plane of symmetry of the part, for all complex cuts, for inclined cuts. Cutting planes that coincide with the symmetry planes of the part when making simple cuts may not be marked.

A local cut is used to identify the surface of a part in a separate, limited location. It is done in the view using a thin wavy line that should not match any other wavy lines in the image.

When making any cuts, the part of the object that falls into the cutting plane is covered with shading. Hatching is applied with continuous thin lines of thickness S/3 - S/2 at an angle of 45 0 to the line of the drawing frame. The shading frequency should be in the range from 1 - 10 mm depending on the image scale. Typically, dashed lines are applied at a distance of 3 to 5 mm. For metal products, one-sided shading is accepted. The same part is hatched in the same way (shading direction and distance between strokes) in all images.