Scales (device). Means of measuring mass What device is used to measure body mass in physics?

To correctly answer the question posed in the task, it is necessary to distinguish them from each other.

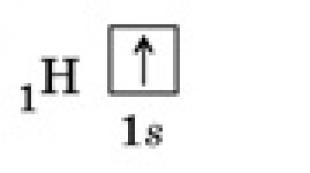

Body weight is a physical characteristic that does not depend on any factors. It remains constant anywhere in the Universe. Its unit of measurement is kilogram. The physical essence at the conceptual level lies in the body’s ability to quickly change its speed, for example, to slow down to a complete stop.

The weight of a body characterizes the force with which it presses on the surface. Moreover, like any force, it depends on the acceleration given to the body. On our planet, all bodies are subject to the same acceleration (gravitational acceleration; 9.8 m/s2). Accordingly, on another planet, body weight will change.

Gravity is the force with which a planet attracts a body; it is numerically equal to the weight of the body.

Devices for measuring weight and body weight

The instrument for measuring mass is the well-known scale. The first type of scales were mechanical ones, which are still widely used today. Later they were joined by electronic scales, which have very high measurement accuracy.

In order to measure body weight, you need to use a device called a dynamometer. Its name is translated as a force meter, which corresponds to the meaning of the term body weight defined in the previous section. Just like scales, they come in mechanical types (lever, spring) and electronic. Weight is measured in Newtons.

"Electrical Appliances" - Lamp sockets, etc. Mixer. Thermal. Electrical engineering. Goals and objectives. Circuit breakers. Household electrical appliances. Educational topic: Household electrical appliances. Alternating current. Direct current. Electrical installation devices. Wiring. Types of electrical wiring. Appliances. The list of electrical appliances is very long.

“Weight and mass” - Progress of the experiment. WEIGHT and WEIGHTLESSNESS. Scientific data and observations. Project overview. You can get closer to weightlessness if you move at a certain speed along a convex trajectory. Who and when first began to study the fall of bodies in the air? The book “Unsolved Mysteries of Humanity” published by Reader's Digest.

“Weight of the backpack” - Recommendations for students: Weigh the backpacks without school supplies from the students in our class. Perform exercises to strengthen the muscles of the torso. Subject of research: schoolchildren’s posture. Project - research. I will maintain my health, I will help myself. Our backpacks. Research results: “What’s in our backpacks?”

“Magnifying devices” - Lenses. A hand-held magnifying glass provides magnification from 2 to 20 times. The product will indicate the magnification that the microscope is currently providing. Tripod. Historical reference. Biology is the science of life, living organisms living on earth. Tube. Biology is the science of life. Laboratory work No. 1. 4. Place the finished preparation on the stage opposite the hole in it.

“Weight and air pressure” - What is the atmosphere? How can you weigh gas? What causes atmospheric pressure? Does the atmosphere have weight? Measuring atmospheric pressure. Let's answer the questions: Can the atmosphere “pressure”? What causes gas pressure? Why does water rise after the piston? What is the name of the device for measuring atmospheric pressure?

“Measuring instruments” - The thermometer is a glass tube sealed on both sides. Pressure gauge. Dynamometer. Medical dynamometer. To measure means to compare one quantity with another. Each device has a scale (division). Aneroid barometer. Barometer. Thermometer. Devices make human life a lot easier. Strength meter. Types of dynamometers.

General information

Modern scales are a complex mechanism that, in addition to weighing, can provide registration of weighing results, signaling in case of mass deviation from specified technological standards and other operations.

1.1. Laboratory equal-arm scales(Fig. 4.1) consist of a rocker arm 1 mounted using a support prism 2 on the flange 3 of the base of the scales. The rocker arm has two load-receiving prisms 5, 11 through which, using cushions 4 and 12, suspensions 6 and 10 are connected to the rocker arm 1. The scale 8 of the optical reading device is rigidly attached to the rocker arm. When measuring mass, a weighed load 9 with a mass m is installed on one pan of the scale, and balancing weights 7 with a mass m g are placed on the second pan. If m > m g, then the balance beam is deflected by an angle φ (Fig. 4.2).

The VLR-20 scales (Fig. 4.3) have a maximum weighing limit of 20 g and a dividing device division value of 0.005 mg.

A hollow stand 9 is installed on the base of 6 scales; a bracket with insulating levers 11 and a support pad 15 are attached to the upper part of the rack. An illuminator 5, a condenser 4 and a lens 3 of an optical reading device are installed on the base 6. A support prism 17, saddles with load-receiving prisms 13 and a pointer 1 with a microscale 2 are fixed to the equal-arm rocker arm 16.

The equilibrium position of the moving system on the rocker arm is adjusted using calibration nuts 19 at the ends of the rocker arm. By adjusting the position of the center of gravity of the rocker by vertically moving the adjusting nuts 18 located in the middle of the rocker, it is possible to set the specified weight division price. The load-receiving prisms 13 support the cushions 14 of the earrings 12, on which the pendants with the load-receiving cups 7 are suspended.

The scales have two air dampers 10. The upper part of the damper is suspended on an earring, and the lower part is mounted on a board 8 at the top of the scales.

The weight application mechanism 20, located on the board 8, allows you to hang weights weighing 10 on the right suspension; 20; 30 and 30 mg, providing balancing with built-in weights ranging from 10 to 90 mg. The mass of the applied weights is counted on a digitized dial connected to the weight application mechanism.

An optical reading device is used to project a scale image onto a screen using an illuminator, a condenser, a lens and a system of mirrors and allows the change in mass to be measured in the range from 0 to 10 mg. The scale has 100 reading divisions with a division value of 0.1 mg. The dividing mechanism of the optical reading device allows one division of the scale to be divided into 20 parts and, increasing the resolution of the reading, provides a measurement result with a resolution of 0.005 mg.

1.2. Laboratory double prism balance(Fig. 4.5) consist of an asymmetrical rocker 1, installed with the help of a support prism 2 on the pad 5 of the base of the scales. A suspension 9 with a load-receiving cup is connected to one arm of the rocker through a load-receiving prism 6 and a cushion 11. A rail 10 is attached to the same suspension, on which built-in weights 7 are hung, with a total mass of T 0 . A counterweight 4 is attached to the other arm of the rocker arm, balancing the rocker arm. The microscale 3 of the optical reading device is rigidly attached to the rocker 1. When measuring mass, a weighing weight 8 with a mass of T 1, and from the rack using a weight mechanism, part of the weights 7 with a mass of T T.

If T 1 > T g, then the balance beam deviates by an angle φ (Fig. 4.6). In this case, the gravitational moment of stability will be

Where T P, T etc, T k - mass of suspension, counterweight, rocker arm; T about and T 1 - mass of all built-in weights and load; T g - mass of removed weights; A 1 - distance from the axis of rotation of the rocker to the points of contact of the load-receiving prism with the suspension cushion; A 2 - distance from the axis of rotation of the rocker to the center of gravity of the counterweight; A k is the distance from the axis of rotation of the rocker to its center of gravity, α 1, α 2 are angles depending on the installation of the lines of the rocker prisms; g = 9.81 m/s2.

Compensating moment

Error δ y, depending on the gravitational moment of stability and the angle of deviation φ, is determined by the formula:

(4.3)

(4.3)

Error δ to, depending on the compensating moment, will be

![]() (4.4)

(4.4)

Scales VLDP-100 (Fig. 4.4) with the largest weighing limit of 100 g, with a named scale and built-in weights for full load. The scales have a pre-weighing device that allows you to increase the speed of mass measurement and simplify weighing operations associated with the selection of weights that balance the moving scale system.

On the short arm of the rocker 1 there is a saddle with a load-receiving prism 9, and on the long arm there is a counterweight, an air damper disk and a microscale 4 of the optical device. During weighing, an earring 11 rests on the load-receiving prism 9 of the rocker arm with a cushion 10, to which a suspension 7 with a load-receiving cup 6 is attached.

The scales have a weighting mechanism 8, which serves to remove from the suspension and apply three decades of built-in weights weighing 0.1-0.9 to it; 1-9 and 10-90

The pre-weighing mechanism has a horizontal lever 3, whose free end rests against the rocker arm. The second end of the lever is rigidly attached to a torsion spring, the axis of rotation of which is parallel to the axis of rotation of the rocker arm.

Rice. 4.1. Equal-armed scales Rice. 4.1. Equal-armed scales |  Rice. 4.2. Scheme of the action of forces in equal-armed scales Rice. 4.2. Scheme of the action of forces in equal-armed scales |

|

Rice. 4.3. Laboratory equal-arm scales VLR-20 Rice. 4.3. Laboratory equal-arm scales VLR-20 |   Rice. 4.4. Laboratory scales VLDP-100 Rice. 4.4. Laboratory scales VLDP-100 |

|

Rice. 4.5. Double prism scales Rice. 4.5. Double prism scales |  Rice. 4.6. Scheme of the action of forces in two-prism balances Rice. 4.6. Scheme of the action of forces in two-prism balances |

|

The isolating mechanism 5 has three fixed positions: IP - initial position, PV - preliminary weighing, TV - precise weighing.

In the initial position, the rocker arm 1 and the suspension 7 are on the stops of the isolating mechanism 5. The lever of the pre-weighing mechanism is in the lower position, the built-in weights are hung on the suspension.

When weighing a load placed on a cup, the isolating mechanism is first placed in the PV position. In this case, lever 3 rests on the rocker arm, the built-in weights are removed from the suspension, and the suspension is lowered onto the load-receiving prism of the rocker arm. After this, the rocker arm is lowered onto the cushion by the support prism 2, deflected by a certain angle, at which the counteracting moment created by the torsion spring of the pre-weighing mechanism balances the moment proportional to the difference T k = T 0 - T 1 where T 0 - mass of built-in weights; T 1 - mass of the body being weighed.

Using the scale of the optical reading device and the dial of the dividing device, the preliminary value of the measured mass is counted, which is set on the counters of the weighting mechanism.

When moving the isolating mechanism to the TV position, first isolate the rocker arm and suspension, after which weights with a mass of T d. Lever 3 is pulled down all the way, releasing the rocker arm, the suspension is connected to the rocker arm through a load-receiving prism and a cushion, and the rocker arm sits on the cushion with the support prism and precise weighing is performed.

The value of the measured mass is counted by the counter of the weighting mechanism, the scale and the dial of the dividing device.

1.3. Quadrant scales are simple, reliable in operation, and have high accuracy. Unlike other laboratory scales, the weight receiving cup of quadrant scales is located in the upper part, which creates significant ease of use. Quadrant scales are used in production lines, in centralized control systems, and in control systems associated with mass measurement.

Quadrant scales (Fig. 4.7) consist of an asymmetrical rocker 1 (quadrant), installed using a support prism 2 on a corner pad 3, fixed to the base of the scales. The suspension 6, using corner pads 8, is installed on the load-receiving prism 7, mounted on the rocker arm 1. The load-receiving cup 9 in the quadrant scales is attached to the upper part of the suspension 6. To prevent the suspension from tipping over when a load is placed on the cup 9, the lower part of the suspension is attached to the base of the scales through hinge joints using a lever 5 called a string. The microscale 4 of the optical reading device is rigidly attached to the quadrant. A rail is attached to the suspension, on which built-in weights are located.

The use of corner cushions and hinge joints in the lower part of the suspension in quadrant scales made it possible to increase the working angle of deflection φ of the quadrant several times compared to the deflection angle in equal-arm or two-prism scales. For example, in quadrant scales, when the maximum load is applied to the suspension, the deflection angle is 12°, and in equal-arm and double-prism scales it is less than 3°. With a large deflection angle, naturally the range of mass measurement on the scale will also be larger, which makes it possible to reduce the number of built-in weights used in the scales. However, hinges with a string are a source of additional errors, reducing weighing accuracy. Therefore, the quadrant scales produced generally have accuracy class 4.

Laboratory quadrant scales model VLKT-5 (Fig. 4.8) belong to accuracy class 4 and are designed for measuring mass up to 5 kg. The measuring system of scales includes a rocker arm 3, a suspension bracket 2 with a load-receiving cup 1, and a “string” b. The prismatic “string” is one of the sides of the articulated parallelogram. The “string” and steel prisms of the rocker rest on angular self-aligning cushions. To calm the vibrations of the moving system, the scales have a magnetic damper 5. The scales also have a mechanism for compensating for fluctuations in the level of the workplace, a device for compensating the mass of the container and a weighting mechanism. When weighing, special grips driven by the handles of the weighting mechanism are removed from the load-receiving suspension or built-in weights 7 weighing 1; 1 and 2 kg are placed on it. The mass values of the removed weights are counted from a digitized drum associated with the weighting mechanism. The optical reading device includes a backlight, a condenser, a lens and a microscale. 4, mounted on the rocker. The image of the microscale, enlarged with the help of an optical system, is transmitted to the frosted glass of the screen 8, where the value of the mass determined when the rocker deviates from its initial position is indicated.

A cylindrical spiral spring 9, attached at one end to the suspension, is a measuring element of the dividing mechanism. The second end of this spring, connected by a drive to the digitized drum of the mechanical counter, can move vertically when the counter handle of the dividing mechanism is rotated. When the drum of a mechanical counter rotates to a full capacity equal to 100 divisions, the spring stretches, transmitting to the rocker a force equivalent to the force created by changing the mass of the load by 10 g, and the result of the measurement made using the dividing mechanism is counted on the digitized drum of the mechanical counter with a discreteness of 0 ,1 g. The microscale mounted on the rocker has 100 divisions with a division value of 10 g. Therefore, the measuring range of the optical reading device and dividing mechanism with a resolution of 0.1 g is 1000 g.

The quadrant scales model VLKT-500 (Fig. 4.9), designed for measuring mass up to 500 g (measurement error ±0.02 g), are designed in a similar way.

Before measuring body weight at level 1, the scales are installed in a horizontal position using adjustable supports 4. To put the scales into operation, it is necessary to connect the power cord 5 to the electrical network and turn on the switch 2. Using the handle 7, set the digital drum of the mechanical counter to position “00” and use the handwheels 3 (“coarse”) and 6 (“fine”) tare weight compensation devices bring the zero scale division to a symmetrical position. In this case, the handle 9 of the weighting mechanism is in the position for measuring in the range of 1-100 g. The body under study is placed on the load-receiving cup 10 and the handle 7 combines the scale division with the reading marks on the screen 8.

Torsion scales WT-250 (Fig. 4.10) are designed for weighing bodies weighing up to 250 g and have a measurement error of ±0.005 g. The body of the scale rests on three supports, two of which 1 are adjustable and are designed to install the scales in a horizontal position at level 2.

The scale casing has a glass screen 4, through which the dial of the measuring mechanism is visible. Before weighing, turn the lock 9 to unlock the suspension and use the flywheel 10 of the tare weight compensation device to set the pointer 5 to the zero position. The measured body 7 is placed on the suspension 6 and the safety cover 8 is closed. By rotating the flywheel 3 of the movable dial, the pointer 5 is returned to the zero position. In this case, the amount of body weight is determined by the arrow on the dial of the measuring mechanism.

1.4. Electronic digital scales. A significant advantage of the scales is that operations do not require built-in or overhead weights. Therefore, during serial production of scales and during their operation, metal is significantly saved and the number of weights subject to state verification is reduced.

Electronic digital scales of the 4th accuracy class, model VBE-1 kg (Fig. 4.11, a), based on the principle of operation discussed above. These scales have a weighing device I mounted on a base 2, and an electrical part consisting of five printed circuit boards 3, 13, 14 with connectors and mounting brackets, a transformer 15, a sensor 4 that converts linear movements into an electrical signal.

The weighing device has a stand on which a bracket 12 and a magnetic system 16 with a working coil 5 are mounted. The movable scale system consists of two frames 6, a bracket 7 and six springs 8, two of which are intermediate links in the elastic-flexible connection between the frames and the bracket. The working coil is attached to the liner 9, which is rigidly connected to the bracket 7. The movable weighing system is attached through springs 8 so that the coil in the working gap of the magnetic system can only move in the vertical direction. In the upper part of the bracket 7 there is a stand 10, on which the load-receiving cup 11 is installed.

The electrical part of the scales is made on printed circuit boards located in the scales body. The electrical elements that generate heat are located at the rear of the scale and are separated from the weighing device by a heat shield.

The scales have an electronic device that compensates for the force generated by the container. When a container is placed on the load receiving cup, the value of its mass appears on the digital reading device, and after pressing the “Tare” button, this value is transferred to the storage device, and zeros are set on the digital reading device and the scales are ready to measure the mass of the load. The tare compensation device included in the scale compensates for loads weighing up to 1000 g.

Electronic digital scales of the 4th class VLE-1 kg with improved technical characteristics (Fig. 4.11, b). These scales can be widely used in closed technological processes of agro-industrial complexes. They have an output for connecting digital printing devices and computers, semi-automatic calibration and tare weight compensation over the entire weighing range. The terminal provides automatic sorting of items by weight and counting the number of items based on a given value of the mass of one item.

3. Work order: read clause 1; using formulas (4.1)-(4.4) according to the initial conditions (Table 4.1) for two-prism scales, determine: the moment of stability M y, the compensating moment M k, as well as the errors δ y and δ k, and draw up a report.

|  Rice. 4.8. Scheme of quadrant scales VLKT-5 Rice. 4.8. Scheme of quadrant scales VLKT-5 |

Rice. 4.9. General view of the VLKT-500 scales Rice. 4.9. General view of the VLKT-500 scales |

|

A

A  b

b Table 4.1. Initial data for performing the work

| Option No. | T P , G | T etc , G | T To , G | T O , G | A k, m | A 1m | A 2 , m | α 1 = α 2 ,º | φ,º |

| 0,15 | 0,08 | 0,16 | 1,0 | ||||||

| 0,26 | 0,11 | 0,22 | 0,9 | 2,9 | |||||

| 0,32 | 0,17 | 0,32 | 0,8 | 2,8 | |||||

| 0,18 | 0,15 | 0,30 | 0,7 | 2,7 | |||||

| 0,20 | 0,12 | 0,22 | 0,6 | 2,6 | |||||

| 0,16 | 0,09 | 0,17 | 0,5 | 2,5 | |||||

| 0,27 | 0,12 | 0,24 | 1,5 | 2,9 | |||||

| 0,33 | 0,18 | 0,34 | 1,4 | 2,8 | |||||

| 0,19 | 0,16 | 0,31 | 1,3 | 2,7 | |||||

| 0,23 | 0,14 | 0,24 | 1,2 | 2,6 | |||||

| 0,17 | 0,07 | 0,15 | 1,1 | 2,5 | |||||

| 0,28 | 0,13 | 0,27 | 1,0 | 2,4 | |||||

| 0,34 | 0,19 | 0,36 | 2,0 | 3,2 | |||||

| 0,20 | 0,17 | 0,34 | 1,8 | 3,1 | |||||

| 0,21 | 0,15 | 0,25 | 1,7 | 3,0 | |||||

| 0,29 | 0,14 | 0,28 | 1,6 | 2,9 | |||||

| 0,35 | 0,20 | 0,37 | 1,5 | 2,8 | |||||

| 0,21 | 0,18 | 0,36 | 1,4 | 2,7 | |||||

| 0,24 | 0,13 | 0,26 | 1,3 | 2,6 | |||||

| 0,19 | 0,07 | 0,16 | 1,2 | 2,5 | |||||

| 0,30 | 0,15 | 0,29 | 1,1 | 2,4 | |||||

| 0,36 | 0,21 | 0,39 | 1,0 | 2,3 | |||||

| 0,22 | 0,19 | 0,38 | 0,9 | 2,2 | |||||

| 0,21 | 0,11 | 0,23 | 0,8 | 2,1 | |||||

| 0,14 | 0,09 | 0,18 | 0,7 | 2,0 | |||||

| 0,31 | 0,16 | 0,30 | 0,6 | 3,0 | |||||

| 0,37 | 0,22 | 0,41 | 0,5 | 2,9 | |||||

| 0,23 | 0,20 | 0,43 | 1,5 | 2,8 | |||||

| 0,25 | 0,10 | 0,20 | 1,4 | 2,7 | |||||

| 0,18 | 0,06 | 0,14 | 1,3 | 2,6 |

- describe the purpose, design of devices and draw their diagrams (Fig. 4.1

Perform calculations to determine M y, M k, δ y and δ k;

Give answers to security questions.

Control questions

1. How is the equilibrium position of the moving system on the rocker in the VLR-20 scales adjusted?

2. On which arm of the rocker arm is the saddle with the load-receiving prism mounted in the VLDP-100 scales?

3. What is the design difference between quadrant scales and two-prism scales?

4. How are quadrant scales model VLKT-5 designed?

5. How is weighing performed on the VLKT-500 scales?

6. How do electronic scales model VBE-1 work?

Laboratory and practical work No. 5

Scales (device) Scales, a device for determining the mass of bodies by the force of gravity acting on them. V. is sometimes also called instruments for measuring other physical quantities that are converted for this purpose into force or moment of force. Such devices include, for example, current scales And Pendant scales. The sequence of actions when determining the mass of bodies in the east is discussed in Art. Weighing.

V. is one of the oldest devices. They arose and improved with the development of trade, production and science. The simplest V. in the form of an equal-arm rocker with suspended cups ( rice. 1) were widely used in barter trade in Ancient Babylon (2.5 thousand years BC) and Egypt (2 thousand years BC). Somewhat later, unequal-shoulder V. with a movable weight appeared (see. Steelyard). Already in the 4th century. BC e. Aristotle gave a theory of such V. (rule moments of force). In the 12th century The Arab scientist al-Khazini described cups with cups whose error did not exceed 0.1%. They were used to determine the density of various substances, which made it possible to recognize alloys, identify counterfeit coins, distinguish precious stones from counterfeit ones, etc. In 1586 Galileo to determine the density of bodies, he designed special hydrostatic waves. The general theory of waves was developed by L. Euler (1747).

The development of industry and transport led to the creation of vehicles designed for heavy loads. At the beginning of the 19th century. decimal Vs were created. ( rice. 2) (with a weight-to-load ratio of 1:10 - Quintenz, 1818) and hundredth V. (V. Fairbanks, 1831). At the end of the 19th - beginning of the 20th centuries. With the development of continuous production, weighing machines appeared for continuous weighing (conveyor, dosing, etc.). In various branches of agriculture, industry, and transport, weighers of a wide variety of designs began to be used for weighing specific types of products (in agriculture, for example, grain, root crops, eggs, etc.; in transport - cars, railways. cars, airplanes; in industry - from the smallest parts and components in precision instrument making to multi-ton ingots in metallurgy). For scientific research, designs of precision tests were developed - analytical, microanalytical, assay, etc.

Depending on their purpose, weights are divided into standard (for calibrating weights), laboratory (including analytical) and general purpose, used in various fields of science, technology and the national economy.

According to the principle of operation, voltages are divided into lever, spring, electric strain gauge, hydrostatic, and hydraulic.

Lever valves are the most common; their action is based on the law of equilibrium. lever The fulcrum of the lever (“rocker arms” V.) can be in the middle (equal-arm V.) or be shifted relative to the middle (unequal-arm and single-arm V.). Many lever machines (for example, commercial, automobile, portion, etc.) are a combination of levers of the 1st and 2nd types. The supports for the levers are usually prisms and cushions made of special steel or hard stone (agate, corundum). On equal-arm lever weights, the body being weighed is balanced by weights, and some excess (usually 0.05 – 0.1%) of the weight of the weights over the weight of the body (or vice versa) is compensated by the moment created by the rocker arm (with an arrow) due to the displacement of its center of gravity relative to the original position ( rice. 3). The load compensated by the displacement of the center of gravity of the rocker arm is measured using a reading scale. The value of division s of the lever V. scale is determined by the formula

s = k(P o c / lg),

where P 0

‒ weight of the rocker arm with arrow, c ‒ distance between the center of gravity of the rocker arm and the axis of its rotation, l ‒ length of the rocker arm, g ‒ acceleration

free fall, k is a coefficient that depends only on the resolution of the reading device. The division value, and, consequently, the sensitivity of the V., can be changed within certain limits (usually by moving a special weight that changes the distance c).

In a number of lever laboratory V., part of the measured load is compensated by the force of electromagnetic interaction - retraction of the iron core connected to the rocker arm into a stationary solenoid. The current strength in the solenoid is regulated by an electronic device that brings the voltage to equilibrium. By measuring the current strength, they determine the load V proportional to it. V. of this type are brought to the equilibrium position automatically, so they are usually used for measuring changing masses (for example, when studying oxidation processes, condensation, etc.), when it is inconvenient or impossible to use conventional V. The center of gravity of the rocker arm is combined in these V. with the axis of rotation.

In laboratory practice, weights (especially analytical ones) with built-in weights for part of the load or for the full load are increasingly being used ( rice. 4). The principle of operation of such V. was proposed by D.I. Mendeleev. Specially shaped weights are suspended from the shoulder on which the load cup is located (single-arm weights), or (less commonly) from the opposite shoulder. In single-arm V. ( rice. 5) the error due to the unequal arms of the rocker is completely eliminated.

Modern laboratory scales (analytical, etc.) are equipped with a number of devices to increase the accuracy and speed of weighing: vibration dampers of cups (air or magnetic), doors, when opened, there is almost no air flow, heat shields, mechanisms for applying and removing built-in weights, automatically operating mechanisms for selecting built-in weights when balancing B. Projection scales are increasingly being used, making it possible to expand the range of measurements on the reference scale at small angles of deflection of the rocker arm. All this allows you to significantly increase the performance of V.

In high-speed technical quadrant V. ( rice. 6) the measurement limit on the rocker arm deflection scale is 50 – 100% of the maximum load V., usually lying in the range of 20 g – 10 kg. This is achieved by a special design of a heavy rocker arm (quadrant), the center of gravity of which is located significantly below the axis of rotation.

Most types of metrological, standard, analytical, technical, and trade ( rice. 7), medical, carriage, automobile V., as well as automatic and portioned V.

The action of spring and electric strain gauges is based on Hooke’s law (see. Hooke's law).

The sensitive element in spring voltages is a spiral flat or cylindrical spring, which is deformed under the influence of body weight. V.'s readings are measured on a scale along which a pointer connected to a spring moves. It is assumed that after removing the load, the pointer returns to the zero position, that is, no residual deformation occurs in the spring under the influence of the load.

With the help of spring V., they measure not mass, but weight. However, in most cases, the spring scale is graduated in units of mass. Due to the dependence of the acceleration of gravity on geographic latitude and altitude above sea level, the readings of spring winders depend on their location. In addition, the elastic properties of the spring depend on temperature and change over time; all this reduces the accuracy of spring V.

In torsional (torsional) batteries, the sensitive element is an elastic thread or spiral springs ( rice. 8). The load is determined by the angle of twist of the spring thread, which is proportional to the torsional moment created by the load.

The action of electrical strain gauges is based on converting the deformation of elastic elements (columns, plates, rings) that perceive the force of a load into a change in electrical resistance. The transducers are highly sensitive wire strain gauges, glued to elastic elements. As a rule, electric strain gauges (carriage, automobile, crane, etc.) are used for weighing large masses.

Hydrostatic measurements are used primarily to determine the density of solids and liquids. Their action is based on Archimedes' law (see. Hydrostatic weighing).

Hydraulic V. are similar in design hydraulic press.

The readings are taken using a pressure gauge calibrated in mass units.

All types of V. are characterized by: 1) ultimate load - the greatest static load that V. can withstand without violating their metrological characteristics; 2) division value - the mass corresponding to a change in the reading by one scale division; 3) the limit of permissible weighing error - the largest permissible difference between the result of one weighing and the actual mass of the body being weighed;

4) permissible variation of readings - the largest permissible difference in V.’s readings when repeatedly weighing the same body.

Weighing errors on some types of V. at maximum load.

Weighing error at maximum load

Metrological..........

Exemplary 1st and 2nd categories

Exemplary 3rd category and

technical 1st class............

Analytical, semi-microanalytical, microanalytical, assay

Medical........................

Household...................

Automotive........................

Carriage................

Torsional...............

1 kg

20 kg ‒ 1 kg

200 g - 2 g

20 kg ‒ 1 kg

200 g ‒2 g

200 g

100 g

20 g

2 g

1 g

150 kg

20 kg

30 kg ‒ 2 kg

50 t ‒ 10 t

150 t ‒ 50 t

1000 mg ‒ 20 mg

5 mg ‒ 0.5 mg

0.005 mg*

20 mg ‒ 0.5 mg*

1.0 mg ‒ 0.01 mg*

100 mg ‒ 20 mg

10 mg - 0.4 mg

1.0 mg ‒ 0.1 mg*

1.0 mg ‒ 0.1 mg*

0.1 mg ‒ 0.01 mg*

0.02 mg ‒ 0.004 mg*

0.01 mg ‒ 0.004 mg*

50 g

10 g

60 g ‒5 g

50 kg ‒ 10 kg

150 kg ‒ 50 kg

1.0 mg - 0.05 mg

0.01 mg - 0.001 mg

* Using precision weighing methods.

Lit.: Rudo N. M., Libra. Theory, structure, adjustment and verification, M. - L., 1957; Malikov L. M., Smirnova N. A., Analytical electric scales, in the book: Encyclopedia of Control and Automation Measurements, v. 1, M. - L., 1962: Orlov S.P., Avdeev B.A., Weighing equipment of enterprises, M., 1962; Karpin E. B., Calculation and design of weighing mechanisms and dispensers, M., 1963; Gauzner S.I., Mikhailovsky S.S., Orlov V.V., Recording devices in automatic weighing processes, M., 1966.

SUBJECT : BODY WEIGHT. UNITS OF POWER. DYNAMOMETER.

The purpose of the lesson : give the concept of body weight, establish the differences between body weight and gravity; enter the unit of force; Find out what device is used to measure body weight.

Equipment: computer, screen, projector, floor scales, dynamometer, measuring cylinders, weights.

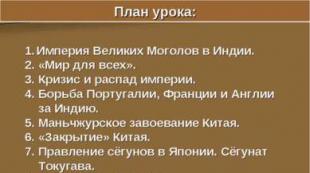

Lesson plan:

Organizational moment (1 min)

Checking homework (7 min)

Learning new material (18 min)

a) Body weight. Units of force.

b) Dynamometers. Types of dynamometers.

c) Body weight and its calculation.

4. Physical education lesson (G. Oster’s problem)

5. Solving the problem. Consolidation of the material covered (10 min)

6. Lesson summary. Homework (1 min)

During the classes.

1. Organizational moment.

2. Updating knowledge.

Let's start the lesson by recalling some physical quantities and terms that we met earlier.

Physical dictation:

What is the magnitude of gravity? What is it measured in?

What is the direction of gravity?

What is the value of elastic force? What is it measured in?

What is the direction of the elastic force?

Write down the formula for Hooke's law?

1) Divide these physical quantities into vector and scalar: mass, gravity, speed, time, length, inertia and elastic force.

(scalar: mass, time, length; vector: gravity, speed, elastic force. Inertia is not a physical quantity, it is a phenomenon).

Additional question: define What is called body weight. (this is a physical quantity that is a measure of the inertia of a body).

Additional question: What is deformation? ( deformation is a change in the shape or size of a body )

2) Graphically depict the force of gravity acting on a brick lying on the surface of the Earth.

Bonus question: Why do raindrops fall to the ground instead of flying back to the clouds? ( raindrops are affected by gravity)

So, we have remembered some physical quantities and terms that we met earlier, let's move on.

3. Studying new material.

What is the boy's weight?

Are we right to say that the boy's weight is __ kg?

Let's take a vote. Raise your hands if you think it's right to say this. And now those who think that we are speaking incorrectly. Opinions were divided. Let's not argue who is right and who is wrong. A new topic will help you understand this “ Body weight " Let's write it down in a notebook.

- Weight bodies are physical quantities. We have already developed a plan for studying physical quantities. Remembering it, tell me what we should learn about body weight today?

1. Definition.

2. Vector or scalar.

3. Designation.

4. Formula.

5. Unit of measurement.

6. Measuring device.

These points of the plan will be the goal of our lesson, and besides this, we will answer the question posed.

- (Slide4) The tiger cub lies on the board (support). When a body was placed on a support, not only the support was compressed, but also the body attracted by the Earth. A deformed, compressed body presses on the support with a force called body weight.

If a body is suspended on a thread (suspension), then not only the thread is stretched, but also the body itself.

- We write down: Body weight is the force with which the body, due to attraction to the Earth, acts on a support or suspension.

What do you think, is weight a vector or a scalar quantity? ( since this is strength,then vector size)

Body weight is a vector physical quantity

What is the direction of body weight? To answer this question, remember the direction of gravity. That's right, the force of gravity is always directed vertically downwards, which means the weight of the body too, since this force arises as a result of attraction to the Earth.

Letter designation: P

Formula. P = F cord(the body and support or suspension are stationary or move uniformly and rectilinearly)

Quite often, the weight of a body is equal to the force of gravity acting on it.

F cord attached to the body

R weight attached to the support (suspension)

In what units is force measured?

In honor of the English physicist I. Newton, this unit is named newton - 1H

1kN=1000N; 1N= 0.001kN

F cord = m∙ g– gravity formula

P = F cord = m∙ g m= P/g ; g= P/m

F cord - gravity [N]

m - weight [kg]

g – gravity acceleration [N/kg]

g = 9,8 [N/kg]; g = 10 [N/kg];

(Slide5) in practice they measure the force with which one body acts on another.

To measure strength, use a DYNAMOMETER

Used : for tightening nuts - there is a torque wrench so that the nut is not twisted and tightened securely; measure hand muscle toneForgeneral performance and strength of a person,

Experience Let's take a dynamometer and hang a weight weighing 102 g from it. At rest, its weight is 1 N. And indeed, if the weight hangs motionless on the hook of the dynamometer, then it will show exactly 1 N. But if the dynamometer is swung up, down or left - to the right, it will show that the weight of the weight has changed. In the figure, for example, it is equal to 4 N. The mass of the bodies and the force of gravity did not change.

So, numerous experiments show that the weight of a body is equal to the force of gravity acting on it when the body and its support (suspension) are at rest or moving together uniformly and in a straight line.

P = F cord .

Note also that the numerical values of weight and gravity can be equal, but the points of their application are always different . The force of gravity is always applied to the body itself, and its weight is always applied to the suspension or support.

[P] = [1 Newton] = [1 H]

Exercise 9 (2.3) (we solve)

Summarizing:

What is the name of the device for measuring force?

A dynamometer is a device... (to measure body weight)

What is Misha's weight? Are we right to say that Misha's weight is __ kg?

( no because body weight is measured with a dynamometer) and is measured in N, body weight is measured with a scale --- kg) (Slide 7)

What is the formula for gravity?

What did you find difficult in the lesson?

What turned out to be difficult for you?