Measurement methods types characteristic. Main characteristics and measurement methods. Distribution by counting method

1. According to the accuracy of the error estimate

Technical

Laboratory (research)

with exact error estimation

with an approximate error estimate

Metrological

reference

Checking and verification

2. By connection with the object:

contact

contactless

4. According to the method of obtaining the result:

straight

indirect

cumulative

joint

3. By the nature of the change in the measured value:

static

dynamic

statistical

5. According to the measurement method:

direct evaluation

comparisons with measure:

opposition

differential

null

substitution

additions

6. In relation to the main units:

absolute

relative

7. According to the measurement conditions

equivalent

unequal

9. According to the number of dimensions:

single

multiple

8. By the nature of the measured quantity:

mechanical

electrical and magnetic

thermophysical

optical

physical and chemical

acoustic

radiation

10. According to the degree of sufficiency of measurements:

necessary

redundant

1. Technical measurements – measurements carried out with the help of working measuring instruments. They are used for the purpose of control and management in the production process at enterprises of various industries, in the social sphere, in everyday life. For example, measurements of temperature during the technological process, measurement of the density of a formaldehyde solution during formalin quality control, the running time of 100 meters by an athlete, the mass of three legs on the market. With technical measurements, there is no need to determine and analyze the errors in the results obtained. Therefore, the error attributed to the measuring instrument or the measurement procedure is accepted, which is sufficient to solve this practical problem. Technical measurements are the most widespread type of measurements

Metrological measurements - measurements carried out using standards and exemplary measuring instruments in order to reproduce units of physical quantities and transfer their size to working measuring instruments. Reference measurements- these are measurements of the highest possible accuracy, achievable with the current level of development of engineering and technology, for example, measurements of fundamental physical constants - the absolute value of the acceleration of gravity, the mass of isotopes of chemical elements. V control measurements the error must be determined or confirmed and must not exceed the specified value. This includes measurements performed by laboratories of state metrological supervision. For instance,“GOST 8.024-75 GSI. State Primary Standard and All-Union Verification Scheme for Measuring Instruments for Liquid Density.

Laboratory measurements are intermediate between technical and metrological and can be performed with different accuracy depending on the purpose of the study.

2. Contact measurement method, contact method – the sensitive element of the device is brought into contact with the measurement object. Examples: 1. Measuring the diameter of a shaft with a caliper, measuring clamp, or checking through and through gauges. 2. Measurement of body temperature with a thermometer.

Non-contact measurement method, non-contact method - a measurement method based on the fact that the sensitive element of the measuring instrument is not brought into contact with the object of measurement. Examples: 1. Measure the distance to an object with a radar. 2. Measure the temperature in a blast furnace with a pyrometer.

3. Static measurement – measurement of a physical quantity taken in accordance with a specific measurement task as unchanged over the measurement time. The limits of permissible deviations are not significant in relation to the nominal value of the measured quantity. Examples: 1. Measurement of the electrical conductivity of an electrolyte raster at a constant temperature. 2. Measuring the mass of salt when packing it in bags.

Dynamic measurement – measurement of a physical quantity that varies in size. Notes: 1. The term "dynamic" refers to the quantity being measured. 2. Strictly speaking, all physical quantities are subject to one or another change in time. This convinces of the need to use more and more sensitive measuring instruments, which make it possible to detect changes in values previously considered constant, so the division of measurements into dynamic and static is conditional..

Examples: measurements of variables in the amplitude of signals in electrical engineering, radio engineering, electronics. In analytical chemistry, this is a signal in chromatography, spectrometry, voltammetry. The measurement result is represented by a time-varying value, indicating the time points to which these values correspond.

4. Direct measurements - measurements in which the desired value of the quantity is obtained directly. For example, length is measured directly with a ruler, temperature with a thermometer, force with a dynamometer, current with an ammeter, voltage with a voltmeter, electrical resistance with an ohmmeter, masses on the scales. Direct measurement equation: X= q, wherekX- division value of the measuring instrument.Indirect measurements . Determination of the desired value of a physical quantity based on the results of direct measurements of other physical quantities functionally related to the sought value. For example, the volume of a parallelepiped is found by multiplying three linear quantities (length, width and height); electrical resistance - by dividing the drop of the voltage measured by the voltmeter by the strength of the electric current measured by the ammeter, the concentration of lead in canned fish using the method of atomic absorption spectrometry, stripping voltammetry - according to the calibration graph in coordinates measured property value - concentration. Indirect measurement equation: X= f(y 1 , y 2 ,…,y n ) , where at i –i values-Xvalues founddirect measurements.

Cumulative measurements - simultaneous measurements of several similar (homogeneous) quantities, in which the desired value is found by solving a system of equations obtained by measuring these quantities in various combinations. For example, when determining the concentration of two components from the absorption spectrum, a system of equations is composed: 1 ( 1 )WITH 1 + 2 ( 1 )WITH 2 = A 1

1 ( 2 )WITH 1 + 2 ( 2 )WITH 2 = A 2

where A is the measured value of the optical density of the solution at wavelengths 1 and 2

1 and 2 - molar coefficients of light absorption, tabular values.

Joint measurements - simultaneous (direct and indirect) measurements of two or more dissimilar (heterogeneous) quantities to find a functional relationship between them. For example, resistanceR t conductor at a fixed temperaturetis determined by the formulaR t = R 0 (1 + t), whereR 0 and - respectively resistance at a known temperaturet 0 (usually 20 o C) and temperature coefficient (these quantities are constant and measured by an indirect method); t = t - t 0 - temperature difference;tis the temperature setpoint measured by the direct method.

5. Measurement method – a method or a set of methods for comparing the measured physical quantity with its unit in accordance with the realized measurement principle. The measurement method is usually determined by the design of measuring instruments.

Direct evaluation method - a measurement method in which the value of a quantity is determined directly by the indicating measuring instrument. Example: pressure with a manometer, time with a stopwatch, weight on a dial scale, temperature with a mercury thermometer, etc.

Measure comparison method - a method of measurement in which the quantity being measured is compared with the quantity reproducible by the measure. Example: - measurement of mass on a balance scale with weights (measures), measurement of the content of an element in a sample by comparison with a standard sample of the composition,

Zero measurement method - method of comparison with a measure in which the net effect of the measurand and the measure on the comparator is reduced to zero. Example: measurement of electrical resistance, inductances and capacitances using a fully balanced bridge, weighing on an equal-arm balance

Displacement measurement method – method of comparison with a measure, in which the measurand is replaced by a measure with a known value of the quantity.

Addition measurement method - a method of comparison with a measure, in which the value of the measured quantity is supplemented by a measure of the same quantity in such a way that the comparator is affected by their sum equal to a predetermined value.

Differential measurement method - a method of comparison with a measure, in which the measured quantity is compared with a homogeneous quantity that has a known value. Slightly different from the value of the measured quantity. and at which the difference between the two quantities is measured.

6. Absolute measurement - a measurement based on direct measurements of one or more basic quantities and (or) the use of physical constants, that is, in absolute units. Note - The concept of "absolute measurement" is used as opposed to the concept of "relative measurement" and is considered as a measurement of a quantity in its units.

Relative measurement - measurement of the ratio of a quantity to a quantity of the same name, which plays the role of a unit, or a measurement of a quantity in relation to a quantity of the same name, taken as the initial one, that is, in relative units. Examples: measurement of the transmission value in infrared spectrometry, relative humidity of the air - is the ratio of the amount of water vapor in 1 m 3 air to the amount of water vapor that saturates 1 m 3 air at a given temperature. Relative measurements, other things being equal, can be performed more accurately than absolute ones, since the error in the measure of quantity is not included in the total error.

7. Equivalent measurements - a series of measurements of a quantity, made by measuring instruments of the same accuracy in the same conditions with the same accuracy. Note: before processing a series of measurements, you need to make sure that all measurements of this series are equally accurate.. The procedure for processing equal and unequal measurements is different, it is simpler in the first case.

Unequal measurements - a series of measurements of a certain quantity, performed by measuring instruments of different accuracy and (or) under different conditions. Note - A series of unequal measurements is processed taking into account the weight of individual measurements included in the series.

8. Single measurement – measurement performed once. Note – In many cases, only single measurements are performed in practice. For example, the measurement of a specific point in time by the clock is usually performed once. The practical application of this type of measurement is always associated with large errors. To eliminate a gross error - a miss, two or three single measurements should be carried out and the final result should be found as the arithmetic mean of two or three measurements.

Multiple measurement - measurement of a physical quantity of the same size, the result of which is obtained from several successive measurements, that is, consisting of a number of single measurements, most often more than four. The advantage of multiple measurements is a significant reduction in the influence of random factors on the measurement error.

Currently, there are many types of measurements, distinguished by the physical nature of the measured quantity and factors that determine various conditions and measurement modes. The main types of measurements of physical quantities, including linear-angular ones (GOST 16263–70), are straight, indirect, cumulative, joint, absolute and relative.

Most widely used direct measurements , consisting in the fact that the desired value of the measured quantity is found from experimental data using measuring instruments. The linear size can be set directly on the scales of the ruler, tape measure, caliper, micrometer, the acting force - with a dynamometer, temperature - with a thermometer, etc.

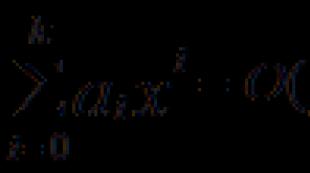

The direct measurement equation has the form:

where Q is the desired value of the measured value; X is the value of the measured quantity obtained directly from the readings of the measuring instruments.

Indirect- such measurements in which the desired value is determined by the known relationship between this value and other quantities obtained by direct measurements.

The indirect measurement equation has the form:

Q \u003d f (x 1, x 2, x 3, ...),

where Q is the desired value of the indirectly measured quantity; х 1 , х 2 , х 3 , ... are the values of quantities measured by the direct type of measurements.

Indirect measurements are used in cases where the desired value is impossible or very difficult to measure directly, i.e. direct measurement, or when the direct measurement gives a less accurate result.

Examples of an indirect type of measurement are the establishment of the volume of a parallelepiped by multiplying three linear quantities (length, height and width) determined using the direct type of measurement, the calculation of engine power, the determination of the electrical resistivity of a conductor by its resistance, length and cross-sectional area, etc.

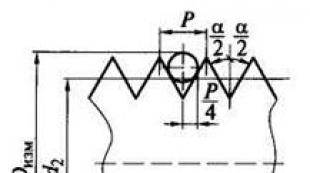

An example of an indirect measurement is also the measurement of the average diameter of an external fastening thread using the "three wires" method. This method is based on the most accurate determination of the average thread diameter d 2 as the diameter of a conditional cylinder, the generatrix of which divides the thread profile into equal parts P / 2 (Fig. 2.1):

where D meas is the distance, including wire diameters, obtained by direct measurements;

d 2 - wire diameter, providing contact with the thread profile at points lying on the generatrix d 2;

α is the angle of the thread profile;

P - thread pitch.

P - thread pitch.

Cumulative measurements carried out by simultaneous measurement of several quantities of the same name, in which the desired value is found by solving a system of equations obtained by direct measurements of various combinations of these quantities. An example of cumulative measurements is the calibration of the weights of a set by the known mass of one of them and by the results of direct comparisons of the masses of different combinations of weights.

For example, it is necessary to calibrate a burnt mass of 1; 2; 5; 10 and 20 kg. An exemplary weight is 1 kg, marked 1 rev.

Let's take measurements, changing the combination of weights each time:

1 = 1 06 + a; 1 + l about = 2 + b; 2 = 2 + With; 1+2 + 2 = 5 + d etc.

Letters a, b, With, d– unknown values of weights that have to be added or subtracted from the mass of the kettlebell. By solving a system of equations, you can determine the value of each weight.

Joint measurements- simultaneous measurements of two or more dissimilar quantities to find the relationship between them, for example, measurements of the volume of a body made with measurements of different temperatures, causing a change in the volume of this body.

The main types of measurements, on the basis of the nature of the measurement results for various physical quantities, include absolute and relative measurements.

Absolute measurements are based on direct measurements of one or more physical quantities. An example of an absolute measurement is measuring the diameter or length of a bead with a caliper or micrometer, or measuring temperature with a thermometer.

Absolute measurements are accompanied by an evaluation of the entire measurand.

Relative measurements are based on measuring the ratio of the measured value, which plays the role of a unit, or measuring the value in relation to the value of the same name, taken as the initial one. As samples, exemplary measures in the form of plane-parallel end blocks of length are often used.

An example of relative measurements can be measurements of the calibers of plugs and staples on horizontal and vertical optimeters with the adjustment of measuring instruments according to exemplary measures. When using exemplary measures or exemplary parts, relative measurements can improve the accuracy of measurement results compared to absolute measurements.

In addition to the considered types of measurement, according to the main feature - the method of obtaining the measurement result, the types of measurements are also classified according to the accuracy of the measurement results - into equivalent and unequal, according to the number of measurements multiple and single, in relation to the change in the measured value in time - by static and dynamic, by the presence of contact of the measuring surface of the measuring instrument with the surface of the product - on contact and contactless and etc.

Depending on the metrological purpose, measurements are divided into technical– production measurements, control and calibration and metrological- measurements with the utmost possible accuracy using standards in order to reproduce units of physical quantities in order to transfer their size to working measuring instruments.

Measurement methods

In accordance with RMG 29–99, the main measurement methods include the method of direct assessment and comparison methods: differential, zero, substitution and coincidence.

direct method- a measurement method in which the value of a quantity is determined directly from the reading device of a direct-acting measuring device, for example, measuring a shaft with a micrometer and force with a mechanical dynamometer.

Measure Comparison Methods- methods in which the measured value is compared with the value reproduced by the measure:

differential method characterized by measuring the difference between the measured value and the known value, the reproducible measure. An example of a differential method is the measurement by a voltmeter of the difference between two voltages, of which one is known with great accuracy, and the other is the desired value;

null method- at which the difference between the measured value and the measure is reduced to zero. At the same time, the zero method has the advantage that the measure can be many times less than the measured value, for example, weighing on a scale, when the weight being weighed is on one arm, and a set of reference weights is on the other;

substitution method- a method of comparison with a measure, in which the measured value is replaced by a known value, reproducible by the measure. The substitution method is used when weighing with the alternate placement of the measured mass and weights on the same scale pan;

match method- a method of comparison with a measure, in which the difference between the measured value and the value reproduced by the measure is measured using the coincidence of scale marks or periodic signals. An example of the use of this method is the measurement of length with a vernier caliper.

Depending on the type of measuring instruments used, there are instrumental, expert, heuristic and organoleptic methods of measurement.

instrumental method based on the use of special technical means, including automated and automatic.

expert method The evaluation is based on the use of the judgments of a group of specialists.

Heuristic methods estimates are based on intuition.

Organoleptic methods estimates are based on the use of the human senses. Assessment of the state of the object can be carried out by element-by-element and complex measurements. The element-by-element method is characterized by the measurement of each product parameter separately. For example, eccentricity, ovality, cutting of a cylindrical shaft. The complex method is characterized by the measurement of the total quality index, which is influenced by its individual components. For example, measuring the radial runout of a cylindrical part, which is affected by eccentricity, ovality, etc.; profile position control along limit contours, etc.

Measurement errors

General provisions. The measurement process is inevitably accompanied by errors that are caused by the imperfection of the measuring instruments, the instability of the measurement conditions, the imperfection of the method itself and the measurement technique, insufficient experience and the imperfection of the sense organs of the person performing the measurements, as well as other factors.

Measurement error the deviation of the measurement result from the true value of the measured quantity is called:

ΔХ izi \u003d X i - X and,

where X j is the i-th value of the measurement result;

X and - the true value of the measured value.

Since the true value of the measured quantity always remains unknown, the arithmetic mean value is taken for it with repeated measurements:

, (2.1)

, (2.1)

where n is the number of measurements taken.

The measurement error (ΔХ izi), expressed in units of the measured quantity, is called absolute. It is not always informative. For example, an absolute error of 0.01 mm can be quite large when measuring values in tenths of a millimeter and small when measuring values larger than a few meters.

A more informative value is the relative error, which is understood as the ratio of the absolute measurement error to its true value (or mathematical expectation),%:

![]() .

.

It is the relative error that is used to characterize the measurement accuracy.

By nature ( patterns of manifestation) measurement errors are divided into systematic, random and gross errors.

Systematic errors. Systematic errors include errors that, when repeated measurements remain constant or change according to some law. Systematic errors in the measurement by the same method and the same measuring instruments always have constant values. The reasons for their appearance include:

– method errors or theoretical errors;

– instrumental errors;

– errors caused by the influence of the environment and measurement conditions.

Method errors occur due to errors or insufficient development of the measurement method. This also includes the illegal extrapolation of a property obtained as a result of a single measurement to the entire measured object. For example, when deciding on the suitability of a shaft by a single measurement, one can make a mistake, since such shape errors as deviations from cylindricity, roundness, longitudinal section profile, etc. are not taken into account. Therefore, in order to exclude such systematic errors in the measurement procedure, it is recommended to carry out measurements in several places of parts and mutually perpendicular directions.

Method errors also include the influence of the tool on the properties of the object (for example, a significant measuring force that changes the shape of a thin-walled part) or errors associated with excessively rough rounding of the measurement result.

Instrumental errors associated with errors in measuring instruments caused by manufacturing errors or wear of the components of the measuring instrument.

to the errors caused influence of the environment and measurement conditions, refer to temperature (for example, measurements of a part that has not yet cooled down), vibrations, non-rigidity of the surface on which the measuring instrument is installed, etc.

One of the methods for detecting a systematic error can be the replacement of a measuring instrument with a similar one if it is supposed to be a source of a systematic error. In a similar way, a systematic error caused by external conditions can be detected: for example, replacing the surface on which the measuring tool is installed with a more rigid one.

The appearance of a systematic error can be detected statistically by plotting the measurement results on paper at specified intervals with specified boundaries (for example, limiting dimensions). A stable movement of the measurement result towards one of the boundaries will mean the appearance of a systematic error and the need for intervention in the technological process.

To eliminate systematic errors in production conditions, measuring instruments are calibrated, those causes that are caused by environmental influences are eliminated, and the measurements themselves are carried out in strict accordance with the recommended methodology, taking measures to improve it, if necessary.

Constant systematic errors do not affect the values of random deviations of measurements from the arithmetic mean, so they are difficult to detect by statistical methods. The analysis of such errors is possible only on the basis of a priori knowledge about the errors obtained, in particular, during the verification of measuring instruments. For example, when checking instruments for measuring linear quantities, the measured value is usually reproduced by an exemplary measure (end measure of length), the actual value of which is known. Systematic errors lead to distortion of the measurement results and therefore must be identified and taken into account when evaluating the measurement results. Completely systematic error is almost impossible to eliminate; always in the process of measurement there remains a certain small quantity, called the non-excluded systematic error. This value is taken into account by making adjustments.

The difference between the arithmetic mean value of the measurement results and the value of the measure with an accuracy determined by the error during its certification is called amendment . It is entered into the certificate of the certified measuring instrument and is taken as the desired systematic error.

Random errors. Random errors are errors that take on repeated measurements of different values, independent in sign and magnitude, not subject to any regularity. There can be many reasons for random errors; for example, fluctuations in the machining allowance, mechanical properties of materials, foreign inclusions, the accuracy of installing parts on the machine, the accuracy of the workpiece measurement tool, changes in the measuring force of fixing the part on the machine, cutting forces, etc.

As a rule, the individual influence of each of these causes on the measurement results is small and cannot be assessed, especially since, like any random event, it may or may not occur in each specific case.

Random errors are subject to a number of conditions:

– small random errors are more common than large ones;

- negative and positive relative to the average measurement value, equal in error, occur equally often;

– each measurement method has its own limit, beyond which errors practically do not occur (otherwise this error will be rough).

The identification of random errors is especially necessary for precise, for example, laboratory measurements. To do this, multiple measurements of the same quantity are used, and their results are processed by methods of probability theory and mathematical statistics. This allows you to refine the results of the measurements.

The influence of random errors is expressed in the scatter of the obtained results relative to the mathematical expectation, therefore, the presence of random errors is well quantified by the standard deviation (RMS).

To estimate the dispersion of the measurement results of the physical quantity X i relative to the average , determined by (2.1), the RMS is determined by the formula

for n ≥ 20 (2.2)

for n ≥ 20 (2.2)

for n ≤ 20, (2.3)

for n ≤ 20, (2.3)

where n is the number of measurements.

Since the average value of a series of measurements is a random approximation to the true value of the measured quantity, then to assess the possible deviations of the average value, the experimental RMS - S is used:

. (2.4)

. (2.4)

The value of S is used when estimating the errors of the final result.

Random measurement errors, without changing the accuracy of the measurement result, nevertheless, affect its reliability.

In this case, the dispersion of the arithmetic mean of a series of measurements always has a smaller error than the error of each specific measurement. It follows from formulas (2.2) and (2.3) that if it is necessary to increase the accuracy of the result (with the systematic error excluded) by a factor of 2, then the number of measurements must be increased by a factor of 4.

Gross errors (misses). Gross errors are errors that are not characteristic of the technological process or result, leading to obvious distortions of the measurement results. Most often, they are allowed by unqualified personnel due to improper handling of the measuring instrument, incorrect reading of readings, recording errors, or due to a sudden extraneous cause during the implementation of technological processes for processing parts. They are immediately visible among the obtained results, since the obtained values differ from the rest of the values of the set of measurements.

If during the measurement process it is possible to find the causes that cause significant differences, and after eliminating these causes, repeated measurements do not confirm such differences, then such measurements can be excluded from consideration. But the thoughtless rejection of measurements that are sharply different from other results can lead to a significant distortion of the measurement characteristics. Sometimes, when processing measurement results, it is not possible to take into account all the circumstances under which they were obtained. In this case, when estimating gross errors, one has to resort to the usual methods of testing statistical hypotheses.

The tested hypothesis consists in the assertion that the measurement result X i does not contain a gross error, but is one of the values of a random variable. Usually check the largest X m ah and the smallest X min values of the measurement results. The following criteria are used to test hypotheses.

1) If the number of measurements is n ≤ 10, then Chauviné criterion. In this case, a gross error (miss) is the result X i if the difference exceeds the values S, determined depending on the number of measurements:

where σ x is the standard deviation obtained by formula (2.3).

2) Romanovsky criterion, used when the number of measurements is 10< n < 20. При этом вычисляют отношение

and the obtained value of β is compared with the theoretical β t at the chosen significance level q (see Table 2.4). Recall that the significance level is the probability of rejecting the correct hypothesis in a statistical hypothesis test. Usually, when processing the results of measurements, its value is taken in the range of 0.05 ... 0.1. If β exceeds β t, then the result X i is considered a blunder.

Table 2.4

Table of values β t = f(n)

| Significance level q | Number of measurements n | ||||||

| 0,01 | 1,73 | 2,16 | 2,43 | 2,62 | 2,75 | 2,90 | 3,08 |

| 0,02 | 1,72 | 2,13 | 2,37 | 2,54 | 2,66 | 2,80 | 2,96 |

| 0,05 | 1,71 | 2,10 | 2,27 | 2,41 | 2,52 | 2,64 | 2,78 |

| 0,10 | 1,69 | 2,00 | 2,17 | 2,29 | 2,39 | 2,49 | 2,62 |

3) Criterion 3S - the most common. It is used when the number of measurements n ≥ 20…50. In this case, it is considered that the result obtained with a probability of P = 0.003 is unlikely and can be qualified as a miss, i.e., the doubtful result X i should be excluded from the measurements if

Example 1. When measuring the hole Ø20H13(+0.33), the following results were obtained:

Ø20.32; Ø20.18; Ø20.26; Ø20.21; Ø20.28; Ø20.42 mm.

It is necessary to check whether the size Ø20.42 mm is a miss.

Since n = 6, Chauviné's criterion applies:

from equation (2.1) we find

by equation (2.3) we find S

This means that even though the result is outside the specified size limit, it cannot be considered a miss. Therefore, the item should be rejected.

Example 2. When measuring the shaft Ø40h12(-0.25), the following results were obtained: 39.72; 39.75; 39.76; 39.80; 39.81; 39.82; 39.82; 39.83; 39.85; 39.87; 39.88; 39.88; 39.90; 39.91; 39.92; 39.92; 39.93; 39.94; 39.96; 39.98; 39.99 mm.

Since the result of 39.72 mm is outside the smallest size limit and the part can be rejected, it should be determined whether this size is not an oversight.

Since the number of measurements exceeds 20, you can use the S criterion. After processing the measurement results, we get:

39.91mm, S=0.12mm,

then 3S = 3 0.12 = 0.36 mm

Therefore, the measurement result of 39.72 mm cannot be considered a miss and the part must be rejected.

Kolchkov V.I. METROLOGY, STANDARDIZATION AND CERTIFICATION. M.: Tutorial

3. Metrology and technical measurements

3.2. Types and methods of measurements

Measurement- the process of finding the value of a physical quantity empirically using measuring instruments.

The result of the process is the value of the physical quantity Q = qU, where q- numerical value of a physical quantity in accepted units; U- unit of physical quantity. The value of a physical quantity Q found during the measurement is called valid.

Measuring principle- a physical phenomenon or a set of physical phenomena underlying measurements. For example, the measurement of body weight by weighing using gravity proportional to the mass, the measurement of temperature using the thermoelectric effect.

Measurement method- a set of methods for using the principles and means of measurement.

Measuring instruments (SI) are used t Technical means having normalized metrological properties.

There are various types of measurements. The classification of measurement types is carried out based on the nature of the dependence of the measured value on time, the type of measurement equation, the conditions that determine the accuracy of the measurement result and the methods of expressing these results.

- According to the nature of the dependence of the measured value on the measurement time, they distinguish static and dynamic measurements.

Static are measurements in which the measured value remains constant over time. Such measurements are, for example, measurements of product dimensions, constant pressure, temperature, etc.

Dynamic - These are measurements during which the measured value changes with time, for example, the measurement of pressure and temperature when gas is compressed in an engine cylinder.

- According to the method of obtaining results, determined by the type of measurement equation, they distinguish direct, indirect, aggregate and joint measurements.

Direct - These are measurements in which the desired value of a physical quantity is found directly from experimental data. Direct measurements can be expressed by the formula Q = X, where Q- the desired value of the measured quantity, and X- the value directly obtained from the experimental data. Examples of such measurements are: length measurement with a ruler or tape measure, diameter measurement with a caliper or micrometer, angle measurement with a goniometer, temperature measurement with a thermometer, etc.

Indirect - These are measurements in which the value of a quantity is determined on the basis of a known relationship between the desired quantity and the quantities whose values are found by direct measurements. Thus, the value of the measured quantity is calculated by the formula Q = F(x1, x2 ... xN), where Q- the desired value of the measured quantity; F- known functional dependence, x1 , x2, … , xN- values of quantities obtained by direct measurements. Examples of indirect measurements: determining the volume of a body by direct measurements of its geometric dimensions, finding the electrical resistivity of a conductor by its resistance, length and cross-sectional area, measuring the average thread diameter using the three-wire method, etc. Indirect measurements are widespread in cases where the desired value cannot be measured or is too difficult to measure by direct measurement. There are cases when the magnitude can be measured only indirectly, for example, the dimensions of the astronomical or intraatomic order.

Cumulative - these are measurements in which the values of the measured quantities are determined by the results of repeated measurements of one or more quantities of the same name with various combinations of measures or these quantities. The value of the desired quantity is determined by solving a system of equations compiled from the results of several direct measurements. An example of cumulative measurements is the determination of the mass of the individual weights of a set, i.e. carrying out calibration according to the known mass of one of them and according to the results of direct measurements and comparison of the masses of various combinations of weights. Consider an example of cumulative measurements, which consists in calibrating a weight, consisting of weights with a mass of 1, 2, 2*, 5, 10 and 20 kg. A number of weights (except 2*) represent exemplary weights of different sizes. An asterisk marks a weight that has a value other than the exact value of 2 kg. Calibration consists in determining the mass of each weight using one standard weight, for example, using a weight of 1 kg. By changing the combination of weights, we will take measurements. Let's make equations, where we denote the mass of individual weights by numbers, for example, 1abr means the mass of a standard weight of 1 kg, then: 1 = 1abr + a; 1 + 1rev = 2 + b; 2* = 2 + c; 1 + 2 + 2* = 5 + d etc. Additional weights that must be added to or subtracted from the mass of the weight indicated on the right side of the equation to balance the scales are indicated a, b, c, d. By solving this system of equations, you can determine the value of the mass of each weight.

Joint - these are measurements made simultaneously of two or more opposite quantities in order to find a functional relationship between them. Examples of joint measurements are the determination of the length of a rod depending on its temperature or the dependence of the electrical resistance of a conductor on pressure and temperature.

- According to the conditions that determine the accuracy of the result, the measurements are divided into three classes.

1. Measurements of the highest possible accuracy, achievable with the current state of the art. This class includes all high-precision measurements and, first of all, reference measurements related to the maximum possible accuracy of reproduction of the established units of physical quantities. This also includes measurements of physical constants, primarily universal ones, such as the measurement of the absolute value of the gravitational acceleration.

2. Control and verification measurements, the error of which with a certain probability should not exceed a certain given value. This class includes measurements performed by laboratories of state control (supervision) over compliance with the requirements of technical regulations, as well as the state of measuring equipment and factory measuring laboratories. These measurements guarantee the error of the result with a certain probability, not exceeding some predetermined value.

3. Technical measurements , in which the error of the result is determined by the characteristics of the measuring instruments. Examples of technical measurements are measurements performed during the production process in industrial enterprises, in the service sector, etc.

- Depending on the way of expressing the results of measurements, there are absolute and relative measurements.

Absolute refers to measurements that are based on direct measurements of one or more fundamental quantities or on the use of values of physical constants. Examples of absolute measurements are: determining the length in meters, the strength of the electric current in amperes, the acceleration of gravity in meters per second squared.

Relative called measurements in which the desired value is compared with the value of the same name, playing the role of a unit or taken as the original. Examples of relative measurements are: measuring the diameter of the shell by the number of revolutions of the measuring roller, measuring the relative humidity of the air, defined as the ratio of the amount of water vapor in 1 cubic meter of air to the amount of water vapor that saturates 1 cubic meter of air at a given temperature.

- Depending on the method of determining the values of the desired quantities, there are two main methods of measurement method of direct estimation and method of comparison with measure.

Direct evaluation method - a method of measurement in which the value of a quantity is determined directly from the reading device of a direct-acting measuring device. Examples of such measurements are: measuring length with a ruler, measuring parts with a micrometer, goniometer, pressure with a pressure gauge, etc.

Measure comparison method - a method of measurement in which the measured value is compared with the value reproduced by the measure. For example, to measure the diameter of the caliber, the optimeter is set to zero by the block of gauge blocks, and the measurement result is obtained from the indication of the optimeter pointer, which is a deviation from zero. Thus, the measured value is compared with the size of the end block block. There are several varieties of the comparison method:

a) method opposition, at which the measured value and the value reproduced by the measure simultaneously act on the comparison device, which allows you to establish the relationship between these quantities, for example, measuring resistance in a bridge circuit with the inclusion of a diagonal of the indicating device bridge;

b) differential a method in which a measurand is compared with a known quantity reproducible by the measure. This method, for example, determines the deviation of the controlled diameter of the part on the optimeter after it is set to zero by the block of gauge blocks;

v) null method - also a kind of comparison method with a measure, in which the resulting effect of the impact of quantities on the comparison device is brought to zero. This method measures the electrical resistance according to the bridge circuit with its full balancing;

d) with the method coincidences the difference between the measured value and the value reproduced by the measure is determined using the coincidence of scale marks or periodic signals. For example, when measuring with a caliper, the coincidence of the marks of the main and vernier scales is used.

- Depending on how measurement information is obtained, measurements can be contact and non-contact.

- Depending on the type , applied measuring instruments , distinguish instrumental, expert, heuristic and organoleptic measurement methods.

instrumental method based on the use of special technical means, including automated and automatic.

expert method The evaluation is based on the use of the judgments of a group of specialists.

Heuristic methods estimates are based on intuition.

Organoleptic methods estimates are based on the use of the human senses. Assessment of the state of the object can be carried out element-by-element and complex measurements. Element by Element the method is characterized by the measurement of each parameter of the product separately. For example, eccentricity, ovality, cutting of a cylindrical shaft. Complex method characterized by the measurement of the total quality indicator, which is influenced by its individual components. For example, measuring the radial runout of a cylindrical part, which is affected by eccentricity, ovality, etc.; profile position control along limit contours, etc.

Theory Workshop Tasks Information

According to the method of obtaining the values of a physical quantity measurements can be direct, indirect, cumulative and joint, each of which is carried out by absolute and relative methods (see clause 3.2.).

Rice. 3. Classification of types of measurements

Direct measurement- measurement, in which the desired value of the quantity is found directly from the experimental data. Examples of direct measurements are determination of length using linear measures or temperature with a thermometer. Direct measurements form the basis of more complex indirect measurements.

Indirect measurement - measurement in which the desired value of a quantity is found on the basis of a known relationship between this quantity and quantities obtained by direct measurements, for example, trigonometric methods for measuring angles, in which the acute angle of a right triangle is determined from the measured lengths of the legs and hypotenuse, or measuring the average thread diameter using the three-wire method or, the power of the electrical circuit according to the voltage measured by the voltmeter and the current strength by the ammeter, using a known relationship. In some cases, indirect measurements make it possible to obtain more accurate results than direct measurements. For example, the errors of direct measurements of angles with goniometers are an order of magnitude higher than the errors of indirect measurements of angles using sine rulers.

joint called simultaneously measurements of two or more opposite quantities. The purpose of these measurements is to find a functional relationship between quantities.

Example 1 Building a calibration characteristic y = f(x) transmitter when sets of values are measured simultaneously:

X 1 , X 2 , X 3 , …, Xi , …,X n

Y 1 , Y 2 , Y 3 , …, Y i , …, Y n

Example 2. Determining the temperature coefficient of resistance by simultaneously measuring the resistance R and temperature t and then dependency definition a(t) = DR/Dt:

R 1 , R 2 , …, R i , …, R n

t 1 , t 2 , …, t i , …, t n

Cumulative measurements are carried out by simultaneous measurement of several quantities of the same name, at which the desired value is found by solving a system of equations obtained as a result of direct measurements of various combinations of these quantities.

Example: the value of the mass of individual weights of the set is determined by the known value of the mass of one of the weights and by the results of measurements (comparisons) of the masses of various combinations of weights.

There are weights with masses m1, m2, m3.

The mass of the first weight is determined as follows:

The mass of the second weight is determined as the difference between the masses of the first and second weights M 1.2 and the measured mass of the first weight :

The mass of the third weight is determined as the difference between the masses of the first, second and third weights ( M 1,2,3) and the measured masses of the first and second weights ():

This is often the way to improve the accuracy of measurement results.

Aggregate measurements differ from joint measurements only in that several quantities of the same name are measured simultaneously with cumulative measurements, and opposite ones with joint measurements.

Cumulative and joint measurements are often used in the measurement of various parameters and characteristics in the field of electrical engineering.

By the nature of the change in the measured value There are static, dynamic and statistical measurements.

Static– measurements of time-invariant PV, for example, measuring the length of a part at normal temperature.

Dynamic– measurements of time-varying PVs, such as measuring the distance to ground level from a descending aircraft, or the voltage in the AC mains.

Statistical measurements associated with the determination of the characteristics of random processes, sound signals, noise levels, etc.

By accuracy there are measurements with the highest possible accuracy, control and verification and technical.

Measurements with the highest possible accuracy- these are reference measurements related to the accuracy of reproduction of units of a physical quantity, measurements of physical constants. These measurements are determined by the state of the art.

Control and verification– measurements, the error of which should not exceed a certain specified value. These include measurements performed by laboratories of state supervision over the implementation and observance of standards and the state of measuring equipment, measurements by factory measuring laboratories and others carried out using means and methods that guarantee an error not exceeding a predetermined value.

Technical measurements– measurements in which the error of the result is determined by the characteristics of the measuring instruments (MI). This is the most widespread type of measurement, carried out using working measuring instruments, the error of which is known in advance and is considered sufficient to perform this practical task.

Measurements by way of expressing measurement results can also be absolute and relative.

Absolute measurement– measurement based on direct measurements of one or more basic quantities, as well as on the use of values of physical constants. With linear and angular absolute measurements, as a rule, one physical quantity is found, for example, the diameter of a shaft with a caliper. In some cases, the values of the measured quantity are determined by direct reading on the scale of the instrument, calibrated in units of measurement.

Relative measurement- measurement of the ratio of a quantity to a quantity of the same name, which plays the role of a unit. At relative method measurements, an assessment is made of the deviation value of the measured value relative to the size of the setting standard or sample. An example is a measurement on an optimeter or minimeter.

By number of measurements distinguish between single and multiple measurements.

Single measurements- this is one measurement of one quantity, i.e. the number of measurements is equal to the number of measured values. The practical application of this type of measurement is always associated with large errors, therefore, at least three single measurements should be carried out and the final result should be found as the arithmetic mean.

Multiple measurements characterized by an excess of the number of measurements of the number of measured quantities. Usually the minimum number of measurements in this case is more than three. The advantage of multiple measurements is a significant reduction in the influence of random factors on the measurement error.

The given types of measurements include various methods, i.e. methods for solving the measurement problem with theoretical justification according to the accepted methodology.

Measurements are distinguished by the method of obtaining information, by the nature of changes in the measured value during the measurement process, by the amount of measurement information, in relation to the main units.

According to the method of obtaining information, measurements are divided into direct, indirect, cumulative and joint.

Direct measurements - it is a direct comparison of a physical quantity with its measure. For example, when determining the length of an object with a ruler, the desired value (quantitative expression of the length value) is compared with the measure, i.e. ruler.

Indirect measurements differ from direct ones in that the desired value of the quantity is established from the results of direct measurements of such quantities that are associated with the desired specific dependence. So, if you measure the current strength with an ammeter and the voltage with a voltmeter, then by the known functional relationship of all three named quantities, you can calculate the power of the electrical circuit .

Cumulative measurements are associated with the solution of a system of equations compiled from the results of simultaneous measurements of several homogeneous quantities. The solution of the system of equations makes it possible to calculate the desired value.

Joint measurements - these are measurements of two or more inhomogeneous physical quantities to determine the relationship between them.

Cumulative and joint measurements are often used in the measurement of various parameters and characteristics in the field of electrical engineering.

According to the nature of the change in the measured value during the measurement process, there are statistical, dynamic and static measurements.

Statistical measurements associated with the determination of the characteristics of random processes, sound signals, noise levels, etc.

Static measurements occur when the measured value is practically constant.

Dynamic measurements are associated with such quantities that undergo certain changes during the measurement process.

Ideal static and dynamic measurements are rare in practice.

According to the amount of measurement information, single and multiple measurements are distinguished.

Single measurements- this is one measurement of one quantity, i.e. the number of measurements is equal to the number of measured values. The practical application of this type of measurement is always associated with large errors, therefore, at least three single measurements should be carried out and the final result should be found as the arithmetic mean.

Multiple measurements characterized by an excess of the number of measurements of the number of measured quantities. Usually the minimum number of measurements in this case is more than three. The advantage of multiple measurements is a significant reduction in the influence of random factors on the measurement error.

In relation to the basic units of measurement, they are divided into absolute and relative.

Absolute measurements are called those in which direct measurement of one (sometimes several) basic quantity and a physical constant are used. So, in the well-known formula of Einstein E \u003d mc 2 weight ( m) is the basic physical quantity that can be measured directly (by weighing), and the speed of light ( c) is a physical constant.

Relative measurements are based on establishing the ratio of the measured quantity to the homogeneous quantity used as a unit. Naturally, the desired value depends on the unit of measurement used.

Such concepts as "scale of measurements", "principle of measurements", "measurement method" are associated with measurements.

Measurement scale is an ordered set of values of a physical quantity, which serves as the basis for its measurement. Let us explain this concept using the example of temperature scales.

In the Celsius scale, the melting temperature of ice is taken as the reference point, and the boiling point of water is taken as the main interval (reference point). One hundredth of this interval is the unit of temperature (degree Celsius). In the Fahrenheit temperature scale, the melting temperature of a mixture of ice and ammonia (or common salt) is taken as the reference point, and the normal body temperature of a healthy person is taken as a reference point. The unit of temperature (degree Fahrenheit) is one ninety-sixth of the main interval. On this scale, the melting point of ice is +32°F and the boiling point of water is +212°F. Thus, if on the Celsius scale the difference between the boiling point of water and the melting of ice is 100°C, then in Fahrenheit it is 180°F. In this example, we see the role of the adopted scale both in the quantitative value of the measured value, and in the aspect of ensuring the uniformity of measurements. In this case, it is required to find the ratio of unit sizes in order to compare the measurement results, i.e. t o F/t°C.

In metrological practice, several types of scales are known: the scale of names, the scale of order, the scale of intervals, the scale of ratios, etc.

Name scale - it is a kind of qualitative, not quantitative scale, it does not contain zero and units of measurement. An example is the atlas of flowers (color scale). The measurement process consists in a visual comparison of the painted object with color samples (reference samples of the atlas

colors). Since each color has many options, such a comparison is within the power of an experienced expert who has not only practical experience, but also the corresponding special characteristics of visual capabilities.

order scale characterizes the value of the measured quantity in points (scale of earthquakes, wind force, hardness of physical bodies, etc.).

Interval scale(differences) has conditional zero values, and the intervals are set by agreement. Such scales are the time scale, the length scale.

Relationship scale has a natural zero value, and the unit of measurement is established by agreement. For example, a mass scale (usually we say "weights"), starting from zero, can be graduated in different ways depending on the required weighing accuracy. Compare household and analytical