Indicators of an oil field development system. Key development indicators. Stages of oil field development

Oil field development technology is a set of methods used to extract oil from the subsoil. In the above concept of a development system, the presence or absence of an impact on the formation is indicated as one of its determining factors. The need to drill injection wells depends on this factor. The technology of reservoir development is not included in the definition of a development system. With the same systems, different mining technologies can be used. Of course, when designing field development, it is necessary to take into account which system best suits the chosen technology and which development system can most easily achieve the specified indicators.

The development of each oil field is characterized by certain indicators. Let's consider the general indicators inherent in all development technologies. These include the following.

Oil production q n – the main indicator, total for all production wells drilled at the site per unit of time, and average daily production q ns per well. The nature of changes in time of these indicators depends not only on the properties of the formation and the fluids saturating it, but also on the technological operations carried out in the field at various stages of development.

Liquid extraction qf – total oil and water production per unit time. Pure oil is produced from wells in the purely oil-bearing part of the deposit during some dry period of well operation. For most deposits, sooner or later their products begin to become waterlogged. From this point in time, liquid production exceeds oil production.

Gas production q g. This indicator depends on the gas content in the reservoir oil, its mobility relative to the mobility of oil in the reservoir, the ratio of reservoir pressure to saturation pressure, the presence of a gas cap and the field development system. Gas production is characterized using the gas factor, i.e. the ratio of the volume of gas produced from a well per unit of time, reduced to standard conditions, to the production of degassed oil for the same unit of time. The average gas factor as a technological development indicator is determined by the ratio of current gas production to current oil production.

When developing a field while maintaining reservoir pressure above the saturation pressure, the gas factor remains unchanged and therefore the nature of the change in gas production repeats the dynamics of oil production. If during development the reservoir pressure is below the saturation pressure, then the gas factor changes as follows. During development in the dissolved gas mode, the average gas factor first increases, reaches a maximum, and then decreases and tends to zero at reservoir pressure equal to atmospheric pressure. At this moment, the dissolved gas regime switches to the gravitational regime.

The considered indicators reflect the dynamic characteristics of the process of extracting oil, water and gas. To characterize the development process over the entire past period of time, an integral indicator is used - accumulated production. Cumulative oil production reflects the amount of oil produced by a facility over a certain period of time from the start of development, i.e. from the moment the first production well was launched.

Unlike dynamic indicators, accumulated production can only increase. With a decrease in current production, the rate of increase in the corresponding accumulated indicator decreases. If current production is zero, then the growth of the accumulated indicator stops and it remains constant.

In addition to the considered absolute indicators, which quantify the production of oil, water and gas, relative ones are also used, characterizing the process of extracting reservoir products as a share of oil reserves.

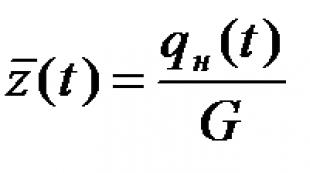

Development rate Z(t)– the ratio of annual oil production to recoverable reserves, expressed as a percentage.

Z(t) = q H ∕ N (1.12)

This indicator changes over time, reflecting the impact on the development process of all technological operations carried out at the field, both during its development and during the regulation process.

Figure 1.7 shows curves characterizing the rate of development over time for two fields with different geological and physical properties. Judging by the given dependencies, the development processes of these fields are significantly different. According to curve 1, four development periods can be distinguished, which we will call stages.

First stage(stage of putting a field into operation), when intensive drilling of wells in the main stock occurs, the development rate continuously increases and reaches its maximum value by the end of the period. Along its length, anhydrous oil is usually produced. Its duration depends on the size of the deposit and the rate of drilling of wells that make up the main fund.

Achieving the maximum annual production of recoverable oil reserves does not always coincide with the completion of well drilling. Sometimes it occurs before the date of drilling the deposit.

1 – deposit A; 2 – deposit B; I, II, III, IV – stages of development

Figure 1.7 – Graph of development rate changes over time

Second stage(the stage of maintaining the achieved maximum level of oil production) is characterized by more or less stable annual oil production. In the field development design assignment, the maximum oil production, the year in which this production should be achieved, and the duration of the second stage are often specified.

The main task of this stage is carried out by drilling reserve wells, regulating well conditions and fully developing a flooding system or another method of influencing the formation. Some wells stop flowing towards the end of the stage, and they are transferred to a mechanized method of operation (using pumps).

Third stage(stage of declining oil production) is characterized by an intensive decrease in the development rate against the background of progressive water cut in well production under water pressure conditions and a sharp increase in the gas factor under gas pressure conditions. Almost all wells are operated mechanized. A significant portion of wells are out of service by the end of this stage.

Fourth stage(final stage of development) is characterized by low development rates. There is a high water cut and a slow decrease in oil production.

The first three stages, during which 70 to 95% of recoverable oil reserves are withdrawn, form the main development period. During the fourth stage, the remaining oil reserves are extracted. However, it is during this period, which generally characterizes the effectiveness of the implemented development system, that the final value of the amount of oil recovered, the total period of field development are determined, and the main volume of associated water is extracted.

As can be seen from Figure 1.10 (curve 2), for some fields it is typical that after the first stage there comes a stage of decline in oil production. Sometimes this happens already during the period when the field is being put into development. This phenomenon is typical for fields with viscous oils or when, by the end of the first stage, high development rates of about 12 - 20% per year or more were achieved. From development experience it follows that the maximum development rate should not exceed 8 - 10% per year, and on average over the entire development period its value should be within 3 - 5% per year.

Let us note once again that the described picture of changes in oil production from a field during its development will occur naturally in the case when the field development technology and, perhaps, the development system remain unchanged over time. In connection with the development of methods for enhancing oil recovery, at some stage of field development, most likely at the third or fourth, a new technology for extracting oil from the subsoil may be applied, as a result of which oil production from the field will again increase.

In the practice of analysis and design of oil field development, indicators are also used that characterize the rate of withdrawal of oil reserves over time: the rate of selection of balance reserves and the rate of selection of residual recoverable reserves. A-priory

(1.13)

(1.13)

Where  – annual oil production in the field depending on the development time; – balance oil reserves.

– annual oil production in the field depending on the development time; – balance oil reserves.

If (1.8) is the development rate, then the relationship between and is expressed by the equality:

(1.14)

(1.14)

where is oil recovery by the end of the field development period.

Rate of extraction of residual recoverable oil reserves:

, (1.15)

, (1.15)

Where  – accumulated oil production for the field depending on the development time.

– accumulated oil production for the field depending on the development time.

Cumulative oil production:

(1.16)

(1.16)

where is the time of field development; – current time.

Current oil recovery or the coefficient of selection of balance reserves is determined from the expression:

(1.17)

(1.17)

By the end of field development, i.e. at , oil recovery:

(1.18)

(1.18)

Product water cut is the ratio of water flow rate to the total flow rate of oil and water. This indicator varies over time from zero to one:

(1.19)

(1.19)

The nature of the change in the indicator depends on a number of factors. One of the main ones is the ratio of oil viscosity to water viscosity in reservoir conditions µ 0:

µ 0 = µ n / µ in (1.20)

Where µ n And µ in– dynamic viscosity of oil and water, respectively.

When developing fields with highly viscous oils, water may appear in the production of some wells from the beginning of their operation. Some deposits with low-viscosity oils are developed for a long time with insignificant water cut. The boundary value between viscous and low-viscosity oils varies from 3 to 4.

The nature of watering of wells and reservoir production is also influenced by the layer-by-layer heterogeneity of the reservoir (with an increase in the degree of heterogeneity, the water-free period of well operation is reduced) and the position of the well perforation interval relative to the oil-water contact.

Experience in the development of oil fields indicates that with low oil viscosity, higher oil recovery is achieved with lower water cut. Consequently, water cut can serve as an indirect indicator of the efficiency of field development. If there is more intensive watering of the product compared to the design, then this may serve as an indicator that the deposit is covered by the waterflooding process to a lesser extent than expected.

Liquid withdrawal rate– the ratio of annual fluid production in reservoir conditions to recoverable oil reserves, expressed in % per year.

If the dynamics of the development rate is characterized by stages, then the change in the rate of fluid withdrawal over time occurs as follows. During the first stage, fluid selection for most fields practically repeats the dynamics of the rate of their development. In the second stage, the rate of liquid withdrawal from some deposits remains constant at the maximum level, from others it decreases, and from others it increases. The same trends are even more pronounced in the third and fourth stages. The change in the rate of fluid withdrawal depends on the oil-water factor, the flow rate of water injected into the reservoir, reservoir pressure and reservoir temperature.

Water-oil factor– the ratio of the current values of water production to oil at the moment of field development, measured in m 3 /t. This parameter, showing how many volumes of water are produced per 1 ton of oil produced, is an indirect indicator of development efficiency and begins to increase rapidly from the third stage of development. The rate of its increase depends on the rate of fluid withdrawal. When developing deposits of low-viscosity oils, ultimately the ratio of the volume of produced water to oil production reaches one, and for viscous oils it increases to 5 - 8 m 3 /t and in some cases reaches 20 m 3 /t.

Consumption of substances injected into the formation. When implementing various technologies to influence the formation, various agents are used to improve the conditions for extracting oil from the subsoil. Water or steam, hydrocarbon gases or air, carbon dioxide and other substances are pumped into the formation. The rate of injection of these substances and their total quantity, as well as the rate of their extraction to the surface with well production, are the most important technological indicators of the development process.

Reservoir pressure. During the development process, the pressure in the formations included in the development object changes compared to the initial one. Moreover, in different parts of the area it will be different: near injection wells it is maximum, and near production wells it is minimum. To monitor changes in reservoir pressure, a weighted average value over the area or volume of the reservoir is used. To determine their weighted average values, isobar maps constructed for different points in time are used.

Important indicators of the intensity of hydrodynamic impact on the formation are pressures at the bottom of injection and production wells. The difference between these values determines the intensity of fluid flow in the formation.

The pressure at the wellhead of production wells is established and maintained based on the requirements for ensuring the collection and in-field transportation of well products.

Reservoir temperaturesA. During the development process, this parameter changes as a result of throttling effects in the near-wellbore zones of the formation, injection of coolants into the formation, and the creation of a moving combustion front in it.

Questions for self-control:

1. Define the concept of “oil field development”.

3. Give examples of hydrodynamic relationships between oil fields and the surrounding water system.

4. How is pressure distributed in an oil reservoir during its development?

OIL FIELD DEVELOPMENT TECHNOLOGY AND TECHNOLOGICAL DEVELOPMENT INDICATORS

Selection of a development system based on the main geological and physical characteristics of the deposit

| Basic geological and physical characteristics | Development system | ||||

| Oil viscosity in pl. conventional mPa*s m n | Mobility µm 2 /mPa*s K/ m n | Sandy formation depth Kp | Well grid density, ha/well | Well placement | Water flooding system |

| 0,5-5,0 | Up to 0.1 | 0,5-0,65 | 16-32 | Row, square. 1-3 rows, 5-7 points. | Linear with focal, area |

| 0,65-0,80 | 20-36 | Inline, 3 rows | Linear with focal | ||

| more than 0.80 | 24-40 | Row, 3-5 rows | Linear with focal | ||

| More than 0.1 | 0,5-0,65 | 24-40 | Inline, 3 rows | Linear with focal | |

| 0,65- 0,80 | 28-40 | Inline, 5 rows | Linear with focal | ||

| More than 0.80 | 33-49 | Inline, 5 rows | Linear with focal | ||

| 5,0-40,0 | Up to 0.1 | 0,5-0,55 | 12-24 | Area, 5-7-9 point | Area |

| 0,65-,80 | 18-28 | ||||

| More than 0.80 | 22-33 | Row, 3 rows. Area, 5-7-9 point | Linear with focal. Area | ||

| More than 0.1 | 0,5-0,65 | 16-28 | Row, 1-3 rows. Area, 5-7-9 point | Linear with focal. Area | |

| 0,65- 0,80 | 22-32 | Row, 1-3 rows. | Linear with focal | ||

| More than 0.80 | 26-36 | Row, 1-3 rows. | Linear with focal |

Oil field development technology is a set of methods used to extract oil from the subsoil. In Section 3, the concept of a development system indicates the presence or absence of impact on the formation as one of its determining factors. The need to drill injection wells depends on this factor. The technology of reservoir development is not included in the definition of a development system. With the same systems, different mining technologies can be used. Of course, when designing field development, it is necessary to take into account which system best suits the chosen technology and which development system can most easily achieve the specified indicators.

The development of each oil field is characterized by certain technological indicators. Let's consider the general indicators inherent in all development technologies. These include the following:

Production oil Q n is the main indicator, total for all production wells drilled at the site per unit of time, and average daily production q n per well.

The nature of changes in time of these indicators depends not only on the properties of the formation and the fluids saturating it, but also on the technological operations carried out in the field at various stages of development.

Liquid extraction Q g - total oil and water production per unit of time (year, month). Pure oil is produced from wells in the purely oil-bearing part of the deposit during some dry period of well operation. For most deposits, sooner or later their products begin to become waterlogged. From this point in time, liquid production exceeds oil production.

In our country, oil and liquid production is measured in weight units - tons. Abroad - in volume - m 3. In the USA, Great Britain and Canada and a number of other countries - in barrels, 1 barrel = 159 liters, in 1 m 3 = 6.29 barrels.

Flow rate of oil, water and liquid q n, q in, q f- respectively, the ratio of oil, water or liquid production to the operating time of the well for a month or a year. It is calculated both for time worked and for calendar time. Unit of measurement - t/day*well.

Water cut - this is the ratio of produced water to the total amount of fluid produced over a period (year, month). Measured in fractions of units. And %:

Water-oil factor- ratio of produced water to oil. Current and accumulated

Gas production Q d. This indicator depends on the gas content in the reservoir oil, its mobility relative to the mobility of oil in the reservoir, the ratio of reservoir pressure to saturation pressure, the presence of a gas cap and the field development system. Gas production is characterized using the gas factor, i.e. the ratio of the volume of gas produced from a well per unit of time, reduced to standard conditions, to the production of degassed oil for the same unit of time. The average gas factor, as a technological indicator of development, is determined by the ratio of current gas production to current oil production.

When developing a field while maintaining reservoir pressure above the saturation pressure, the gas factor remains unchanged and therefore the nature of the change in gas production repeats the dynamics of oil production. If during development the reservoir pressure is below the saturation pressure, then the gas factor changes as follows. During development in the dissolved gas mode, the average gas factor first increases, reaches a maximum, and then decreases and tends to zero at reservoir pressure equal to atmospheric pressure. At this moment, the dissolved gas regime switches to the gravitational regime.

Consumption of agents injected into the formation (Q z) and their extraction along with oil (and gas). When carrying out various technological processes for extracting oil and gas from the subsoil (including to maintain reservoir pressure), water, water with added chemicals, gas and other substances are pumped into the reservoir.

The main indicator characterizing the injection process is compensation for liquid withdrawal by water injection: current and accumulated. Measured in fractions of units. And %.

When drawing up development projects, the value is taken equal to 115% to ensure losses along the route of injected water and friction losses.

The considered indicators reflect the dynamic characteristics of the process of extracting oil, water and gas. To characterize the development process over the entire past period of time, an integral indicator is used - accumulated production (∑Q n, ∑Q w). Cumulative oil and liquid production reflects the amount produced by the facility over a certain period of time from the beginning of development, i.e. from the moment the first production well was launched.

Unlike dynamic indicators, accumulated production can only increase. With a decrease in current production, the rate of increase in the corresponding accumulated indicator decreases. If current production is zero, then the growth of the accumulated indicator stops and it remains constant.

Well stock. Wells are the main component of the oil field development system; oil and associated components are extracted from them; they serve to obtain all information about the deposit and to control the development process. Wells according to their purpose are divided into the following main groups: production, injection, special and auxiliary.

Mining wells make up the largest part of the well stock. Designed for the production of oil, gas and associated components.

Pressure wells are designed for injecting various agents (water, gas, steam) into the reservoir in order to ensure efficient development of oil deposits.

Special wells are designed to conduct various types of research in order to study the parameters and state of development of deposits. Among them there are two subgroups - evaluation and control. The first ones are drilled to assess the oil and gas saturation of the formations. The latter are divided into piezometric and observational.

Auxiliary wells are divided into water intake and absorption wells.

The well stock of each production facility is in constant motion. The total number of production wells changes: at stages I, II - it increases, at stages III, IV - it decreases.

The number of injection wells increases as the waterflood system develops. Wells can move from one group to another.

In addition to the considered absolute indicators, which quantify the production of oil, water and gas, relative ones are also used, characterizing the process of extracting reservoir products as a share of oil reserves.

Rate of selection from NCDs. From your geology course, you know the concept of initial recoverable oil reserves (IRR). When analyzing the development of any facility, indicators such as the rate of selection from NCDs and the degree of NCD production are used. Development pace Z(t), time-varying t, equal to the ratio of current oil production QH(t) to recoverable reserves of the field

This indicator changes over time, reflecting the impact on the development process of all technological operations carried out at the field, both during its development and during the regulation process.

It is clear from the formula that the change in the development rate over time is similar to the change in oil production. To characterize a development system, the concept of maximum development rate is often used. Zmax

Q H max - usually oil production in the second period of development.

The fluid withdrawal rate is determined similarly

The development pace is a measure of the activity of the development system.

Degree of development of initial recoverable oil reserves (IRR)- ratio of accumulated oil production to NCD. Moreover, a comparison of the value of the current water cut of well production with the value of the degree of reserve depletion can indirectly indicate to us whether the object is being developed successfully enough. What does this mean: if these indicators are equal, we can talk about the correct development of the object.

If the degree of production lags behind the water cut of the wells, then it is necessary to take measures to eliminate this. Analysis of development indicators over time will allow us to draw a conclusion either for the use of technologies to intensify oil production, or about the large-scale impact of a particular technology on changing development dynamics.

Oil recovery. The amount of oil reserves of a particular deposit is related to the degree of oil extraction from the subsoil, which is the ratio of the possible total oil production to the balance (geological) oil reserves in the reservoir.

This relationship, called the oil recovery or oil recovery factor, has the form:

η pr - design oil recovery factor

η - current or actual oil recovery factor

There are current and final oil recovery. Under current oil recovery understand the ratio of the amount of oil extracted from the reservoir at the moment of reservoir development to its initial reserves. Final oil recovery- the ratio of the amount of oil produced at the end of development to the initial reserves.

Q inv- recoverable oil reserves

Q score- balance oil reserves

∑Q n- accumulated oil withdrawal

In an ideal case, the oil recovery coefficient tends to reach the value of the displacement coefficient, i.e. the value that can be extracted as much as possible from a formation with specific geological and physical characteristics. But since the process of oil displacement depends on many factors: the structure and characteristics of the reservoir, heterogeneity, properties of the oil saturating it, well placement system, well pattern, oil recovery can be represented as:

h =b out b cool head. b ohv out

Displacement ratio- the ratio of the amount of oil displaced during long-term intensive flushing of the pore space into which the working agent (water) has penetrated to the initial amount of oil in the same volume. Determined experimentally on core.

Waterflood coverage factor- the ratio of the amount of oil displaced from the flushed volume of pore space into which injected or peripheral water passed when flushing it to a given water cut of well production, to the amount of oil displaced from the same volume during its complete flushing, i.e. to the amount of oil determined by the displacement coefficient.

Reservoir sweep coefficient by the displacement process is the ratio of the sum of the volumes of reservoirs covered by the process of oil displacement to the total volume of reservoirs containing oil.

Oil recovery is determined not only for one formation or object, but also for the field as a whole, for a group of fields, and even for an oil-producing region and country.

The final oil recovery is determined not only by the capabilities of oil field development technology, but also by economic conditions.

Pressure distribution in the reservoir.

In the process of oil development

In oil fields, the pressure in the reservoir is constantly changing. On separate

in sections of the formation it will be different. In the area of injection wells there will be

high pressure, low pressure in the mining area.

For assessment, the average or area-weighted pressure is used. Pressures at characteristic points of the formation - at the bottoms of injection wells - are used as development indicators. R n , at the bottoms of production wells - Rn . On the discharge line Rn" on the selection line R s " .

It is also important to determine the pressure differences between the bottoms of injection and production wells, as the difference P n - P s = dP .

Pressure at the wellhead of production wells. It is set based on the requirements for ensuring the collection and transportation of oil, gas and water from wellheads to oil field installations.

Reservoir temperature. This is a natural factor. It can change due to the injection of large volumes of cold water into the formation or, conversely, steam and hot water coolants.

All indicators inherent in this technology for extracting oil from the subsoil are interconnected; a change in some development indicators entails a change in others.

Field development indicators

Technological and technical-economic indicators of the reservoir development process include the current (average annual) and total production of liquid (oil and water), water cut of the produced liquid (the ratio of current water production to the current production of liquid), the current and accumulated water-oil factor (the ratio of water production to production oil), current and accumulated water injection, compensation of injection recovery (the ratio of the injected volume to the volume withdrawn under reservoir conditions), oil recovery factor, number of wells (production and injection), reservoir and bottomhole pressure, current gas factor, average flow rate of production wells and injectivity of injection wells , production costs, labor productivity, capital investments, operating costs, present costs, sales minus transportation costs and taxes, loan requirements, loan fees, loan repayment.

Stages of oil field development

The ratio of annual oil production to initial balance reserves characterizes the pace of field development.

Based on the analysis of the pace of field development, four stages are distinguished (Fig. 5.1): an increasing level of production (I), a constant level of oil production (II), a period of falling oil production (III) and the final period of oil production (IV).

A characteristic feature of the first period is a gradual increase in oil production volumes, due to the continuous commissioning of production wells from drilling. The method of oil production during this period is flowing, there is no water cut. The duration of this stage depends on many factors, the main ones of which are: the amount of recoverable industrial reserves; size of the field and reservoir pressure; thickness and number of productive horizons; properties of productive rocks and the oil itself; availability of funds for field development and others. The duration of the first period is about 4-6 years. The cost of 1 ton of oil during this period is relatively high due to the construction of new wells and field development.

The second stage of development is characterized by a constant level of oil production and minimal cost. During this period, flowing wells are transferred to the mechanized production method due to the progressive water cut of the wells. The decline in oil production during this period is restrained by the commissioning of new reserve wells. The duration of the second stage depends on the rate of oil withdrawal from the field, the amount of recoverable oil reserves, the water cut of well production and the possibility of connecting other horizons of the field to development. The end of the second stage is characterized by the fact that the increase in the volume of injected water for reservoir pressure maintenance does not have a noticeable effect on the volume of oil production and its level begins to decline. Oil water cut at the end of this period can reach 50%. The duration of the period is about 5-7 years. The cost of oil production during this period is the lowest.

Rice. 5.1. Stages of development of an operational facility

The third development period is characterized by a drop in oil production and an increase in produced water production. This stage ends when 80-90% water cut is reached. During this period, all wells operate using mechanized extraction methods; individual wells are taken out of operation due to extreme water cut. The cost of 1 ton of oil during this period begins to increase due to the construction and commissioning of oil dehydration and desalting plants. During this period, main measures are taken to increase well production rates. The duration of this period is 4-6 years.

The fourth stage of development is characterized by large volumes of formation water production and small volumes of oil production. The water cut of the product reaches 90-95% or more. The cost of oil production during this period increases to the limits of profitability. This period is the longest and lasts 15-20 years.

In general, we can conclude that the total duration of development of any oil field is 40-50 years from the beginning to the final profitability. The practice of developing oil fields generally confirms this conclusion.

Development of oil and gas fields? a set of works to extract oil fluid from the reservoir. The extracted oil and associated gas on the surface are subject to primary processing. An oil field is put into development on the basis of a trial operation project, a technological scheme for industrial or pilot-industrial development, or a development project. In the development project, based on exploration and trial operation data, the conditions under which the field will be exploited are determined: its geological structure, reservoir properties of rocks, physical and chemical properties of fluids, saturation of rocks with water, gas, oil, reservoir pressure, temperature, etc. Based on these data, with the help of hydrodynamic calculations, the technical indicators of reservoir operation are established for various development system options, an economic assessment of the options is made, and the optimal one is selected.

Development systems include: identification of development objects, the sequence of putting objects into development, the rate of drilling of fields, methods of influencing productive formations in order to maximize oil recovery; number, ratio, location and order of commissioning of production, injection, control and reserve wells; their operating mode; methods for regulating development processes; environmental protection measures. Does the development system adopted for a particular field predetermine the technical and economic indicators? well flow rate, its change over time, oil recovery factor, capital investments, cost of 1 ton of oil, etc. A rational system for developing oil fields ensures a given level of oil and associated gas production with optimal technical and economic indicators, and effective environmental protection.

The main parameters characterizing the development system: the ratio of the oil-bearing area of the field to the number of all injection and production wells (well grid density), the ratio of the recoverable oil reserves of the field to the number of wells? recoverable reserves per well (development system efficiency), the ratio of the number of injection wells to the number of production wells (reserve production intensity); the ratio of the number of reserve wells drilled after the field was put into development in order to more fully extract oil (reliability of the development system).

The development system is also characterized by geometric parameters: the distance between wells and rows of wells, the width of the strip between injection wells (with block-row development systems), etc.

In a development system without impacting the reservoir with a low-moving oil-bearing contour, a uniform quadrangular (four-point) or triangular (three-point) arrangement of production wells is used; with moving oil-bearing contours, the location of wells takes into account the shape of these contours. Systems for developing oil fields without affecting the reservoir are rarely used in Russia; for the most part, the field is developed with waterflooding. The most widely used is block-row in-circuit flooding. Areal flooding systems are also created with a distance between wells of 400-800 m.

Along with the choice of a development system, the choice of an effective development technology is of great importance. The system and technology are independent in principle; Different development technologies are used for the same system.

Main technological indicators of the development process: current and accumulated production of oil, water, liquids; development rate, water cut in well production, reservoir pressure and temperature, as well as these parameters at characteristic points of the formation and well (at the bottom and wellhead, at the boundaries of elements, etc.); gas factor in individual wells and in the field as a whole. These indicators change over time depending on the formation regimes (the nature of the appearance of in-situ forces that move oil to the bottom of the wells) and development technology. An important indicator of the development of oil fields and the effectiveness of the technology used is the current and final value of oil recovery. Long-term development of oil fields under elastic conditions is possible only in individual cases, because Typically, reservoir pressure drops during development and a dissolved gas regime appears in the reservoir.

The final oil recovery factor during development in this mode is small, rarely reaching (with good formation permeability and low oil viscosity) a value of 0.30-0.35. With the use of waterflooding technology, the final oil recovery factor increases to 0.55-0.6 (on average 0.45-0.5). With increased oil viscosity (20-50*10 -3 Pa*s) it does not exceed 0.3-0.35, and with oil viscosity over 100*10 -3 Pa*s? 0.1.

Waterflooding under these conditions becomes ineffective. To increase the final value of the oil recovery factor, technologies based on physicochemical and thermal methods of influencing the formation are used.

Physico-chemical methods use oil displacement with solvents, high-pressure gas, surfactants, polymer and micellar-polymer solutions, solutions of acids and alkalis.

The use of these technologies makes it possible to reduce the tension at the contact "oil - displacing liquid", or eliminate it (displacement of oil with solvents), improve the wettability of rocks with the displacing liquid, thicken the displacing liquid and thereby reduce the ratio of oil viscosity to liquid viscosity, making the process of displacing oil from formations are more stable and efficient.

Physico-chemical methods of influencing the formation increase oil recovery by 3-5% (surfactants), by 10-15% (polymer and micellar flooding), by 15-20% (carbon dioxide). The use of oil displacement methods with solvents theoretically makes it possible to achieve complete oil recovery.

However, pilot work has revealed a number of difficulties in the practical implementation of these oil extraction methods: sorption of surfactants by the porous medium of reservoirs, changes in their concentration, separation of compositions of substances (micellar-polymer flooding), extraction of only light hydrocarbons (carbon dioxide), reduction of the sweep factor ( solvents and high pressure gas), etc.

Is research also being developed in the field of thermochemical methods for extracting oil under the combined influence of heat and chemical reagents on the formation? thermo-alkaline, thermopolymer flooding, the use of catalysts for in-situ reactions, etc. The possibilities of increasing oil recovery from formations are being explored by influencing them with biochemical methods based on introducing bacteria into the oil reservoir, as a result of whose vital activity substances are formed that improve fluidity and facilitate oil recovery.

There are 4 periods in the development of oil fields: increasing, constant, sharply decreasing and slowly decreasing oil production (late stage).

At all stages of oil field development, control, analysis and regulation of the development process are carried out without changing the development system or with its partial change. Regulating the process of developing oil fields makes it possible to increase the efficiency of oil displacement.

By influencing the deposit, filtration flows are strengthened or weakened, their direction is changed, as a result of which previously undrained areas of the field are drawn into development and the rate of oil withdrawal increases, the production of associated water decreases and the final oil recovery factor increases.

SYSTEM DEVELOPMENT deposits, as mentioned earlier. should be called a set of interrelated engineering solutions that ensure high final oil recovery. Oil field development technology is a set of methods used to extract oil from the subsurface. Reservoir development technology is not included in the definition of a development system. With the same systems, different mining technologies can be used.

Field development is characterized by the use of various categories of wells and certain development indicators.

Based on their purpose, wells are divided into the following categories: prospecting, exploration, and production.

Search engines wells are drilled to search for new oil and gas deposits.

Exploration wells; drilling in areas with established industrial oil and gas potential in order to prepare an estimate of oil and gas reserves, collect initial data for drawing up a project (scheme) for the development of a deposit (field).

Operational wells are divided into production and injection wells. special and auxiliary.

Mining(oil and gas) wells are designed to extract oil, oil and natural gas, and associated components from deposits.

Injection: wells are designed to influence productive formations by injecting water, steam gas and other working agents into them in order to ensure efficient development of deposits. Some injection wells can be temporarily used as production wells.

Reservese wells are provided for the purpose of involving in the development of individual lenses, pinching out zones in stagnant zones, which are not involved in the development of wells of the main stock.

Special wells are designed to conduct various types of research in order to study the parameters and state of development of deposits. Among them there are two subgroups – evaluation and control. The first ones are drilled to assess the oil and gas saturation of the formations. The latter are divided into piezometric and observational. Piezometric wells are designed to monitor changes in formation pressure in the formation. Observation wells for monitoring changes in water-oil contact, gas-oil contact, oil and gas water saturation of the formation.

Auxiliary wells are divided into water intake and absorption wells.

Water intake Designed for water supply during drilling and for reservoir pressure maintenance systems.

Absorbing designed for pumping produced water into absorption horizons.

In addition to the above, oil and gas producing enterprises may have mothballed wells on their balance sheets.

TO preserved These include wells that are not operating in the field due to the inexpediency or impossibility of their operation in a given period.

The well stock of each production facility is in constant motion. The number of injection wells increases as the waterflood system develops. Wells can move from one group to another.

Prenderedand developments:

OIL PRODUCTION- Qn is the main indicator, total for all production wells drilled at the site per unit of time, and the average daily production Qns per well.

Oil production in our country is measured in weight units - tons. Abroad in the USA, UK, Canada and others in barrels.

1 barrel – 159 liters. 1m 3 – 6.29 barrel.

Liquid extraction-Qzh is the total production of oil and water per unit of time. Pure oil is produced from wells in the purely oil-bearing part of the deposit during some dry period of well operation. At a certain stage of development, water begins to flow from the reservoir along with oil and gas.

Liquid production is the total production of oil and water

Q AND = Q H + Q IN

Gas production Qg. . Gas production. During operation, so-called associated gas is produced along with oil. Gas production depends on the gas content in the reservoir oil and is characterized by the gas factor.

The gas factor is the volume of produced gas, reduced to standard conditions, per ton of oil.

= m 3 /t

= m 3 /t

The average gas factor is the ratio of current gas production to current oil production.

Cumulative production oil reflects the amount of oil produced by the facility over a certain period of time from the beginning of development, Cumulative oil production

,

(1.8)

,

(1.8)

Where  - field development time;

- field development time;  -current time.

-current time.

The accumulated production can only increase.

In addition to the considered absolute indicators, relative ones are also used, characterizing the process of extracting reservoir products as a share of oil reserves.

Oil recovery

This is the ratio of the amount of oil extracted from the reservoir to its original reserves in the reservoir. There are current and final oil recovery.

Current oil recovery expresses the ratio of accumulated oil production during a given period of operation of a field to its geological reserves

Final oil recovery– is the ratio of the recoverable reserves of the field to the geological

The final oil recovery ultimately characterizes the quality and efficiency of development of a given field.

Oil recovery is expressed in fractions of units.

Development pace

- the ratio of annual oil production to recoverable reserves, expressed as a percentage.

- the ratio of annual oil production to recoverable reserves, expressed as a percentage.

This indicator changes over time, reflecting the impact on the development process of all technological operations carried out at the field, both during its development and during the regulation process.

Product water cut

- the ratio of water flow to the total flow of oil and water. This indicator varies over time from zero to one:

- the ratio of water flow to the total flow of oil and water. This indicator varies over time from zero to one:

.

(1.21)

.

(1.21)

The nature of the change in the indicator  depends on a number of factors. One of the main ones is the ratio of oil viscosity to water viscosity in reservoir conditions

depends on a number of factors. One of the main ones is the ratio of oil viscosity to water viscosity in reservoir conditions  :

:

Where  And

And  - dynamic viscosity of oil and water, respectively.

- dynamic viscosity of oil and water, respectively.

When developing fields with highly viscous oils, water may appear in the production of some wells from the beginning of their operation. Some deposits with low-viscosity oils are developed for a long time with insignificant water cut. Limit value  between viscous and low-viscosity oils varies from 3 to 4.

between viscous and low-viscosity oils varies from 3 to 4.

The nature of water supply to the wells and reservoir is also influenced by the layer-by-layer heterogeneity of the reservoir (with an increase in the degree of heterogeneity, the water-free period of well operation is reduced) and the position of the well perforation interval relative to the oil-water contact.

Experience in the development of oil fields indicates that with low oil viscosity, higher oil recovery is achieved with lower water cut. Consequently, water cut can serve as an indirect indicator of the efficiency of field development. If there is more intensive watering of the product compared to the design, then this may serve as an indicator that the deposit is covered by the waterflooding process to a lesser extent than expected.

Water-oil factor- the ratio of the current values of water production to oil at the moment of field development, measured in  . This parameter, showing how many volumes of water are produced per 1 ton of oil produced, is an indirect indicator of development efficiency. The rate of its increase depends on the rate of fluid withdrawal. When developing deposits of low-viscosity oils, ultimately the ratio of the volume of produced water to oil production reaches one, and for viscous oils it increases to 5 - 8 m 3 /t and in some cases reaches 20 m 3 /t.

. This parameter, showing how many volumes of water are produced per 1 ton of oil produced, is an indirect indicator of development efficiency. The rate of its increase depends on the rate of fluid withdrawal. When developing deposits of low-viscosity oils, ultimately the ratio of the volume of produced water to oil production reaches one, and for viscous oils it increases to 5 - 8 m 3 /t and in some cases reaches 20 m 3 /t.

Consumption of substances injected into the formation. When implementing various technologies to influence the formation, various agents are used to improve the conditions for extracting oil from the subsoil. Water or steam, hydrocarbon gases or air, carbon dioxide and other substances are pumped into the formation.

Reservoir pressure. During the development process, the pressure in the formations included in the development object changes compared to the initial one. Moreover, in different parts of the area it will be different: near injection wells it is maximum, and near production wells it is minimum. To monitor changes in reservoir pressure, a weighted average value over the area or volume of the reservoir is used. Important indicators of the intensity of hydrodynamic impact on the formation are pressures at the bottom of injection and production wells. The difference between these values determines the intensity of fluid flow in the formation.

The pressure at the wellhead of production wells is established and maintained based on the requirements for ensuring the collection and in-field transportation of well products.

Reservoir temperature. During the development process, this parameter changes as a result of throttling effects in the near-wellbore zones of the formation, injection of coolants into the formation, and the creation of a moving combustion front in it.

It should be noted that all indicators inherent in this technology for extracting oil and gas from the subsoil under a given field development system are interconnected. A change in some indicators may lead to a change in others. If some of the indicators are specified, then others must be calculated.