Concept and classification of measurements. Brief description of the main types of measurements. Types and methods of measurements Measurement methods and their characteristics

Measurement refers to the process of physically comparing a given quantity with a certain value taken as a unit of measurement. Measurement is a cognitive process consisting in experimentally comparing a measured value with a certain value taken as a unit of measurement. parameters of real objects; measurement requires experiments; To conduct experiments, special technical means are required - measuring instruments; 4, the result of the measurement is the value of a physical quantity.

Share your work on social networks

If this work does not suit you, at the bottom of the page there is a list of similar works. You can also use the search button

Main characteristics and measurement methods

1 Definitions and classification of measurements

3 Basic measurement characteristics

1 Definitions and classification of measurements.

Measurement finding the value of a physical quantity experimentally using special technical means. Measurement refers to the process of physically comparing a given quantity with a certain value taken as a unit of measurement.

Measurement a cognitive process consisting in experimentally comparing a measured value with a certain value taken as a unit of measurement.

From the definition of measurements follow the characteristics of measurements:

1) only physical quantities are measured, i.e. parameters of real objects;

2) measurement requires experiments;

3) to conduct experiments, special technical means are required - measuring instruments;

4) the result of the measurement is the value of a physical quantity.

The basic measurement equation is as follows:

A = a X, (1)

where A is the measured value, and is the unit of measurement; X numerical value of the measured quantity with the selected unit of measurement. From the equation follow the terms of the measurement process:

- reproduction of a unit of physical quantity in the form of a measure;

- conversion of the measured signal;

- comparison of the measured quantity with the measure;

- recording the measurement result.

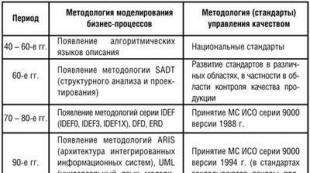

Depending on the method of finding the value of the measured quantity, measurements are divided into:

- straight;

- indirect;

- cumulative;

- joint.

Direct It is called a measurement when the desired value of a physical quantity is found directly from experimental data. It should be noted that direct measurements are often understood as those in which no intermediate transformations are made. This is, for example, measuring voltage and current with well-known electrical measuring instruments - voltmeters and ammeters. Direct measurements are very common in metrological practice. Mathematically, direct measurements can be characterized by the elementary formula

A = x, (2)

where x the value of a quantity found by measuring it and calledmeasurement result.

Indirect is a measurement in which the desired value of a quantity is found on the basis of a known relationship between this quantity and quantities subjected to direct measurements. Indirect measurements can be characterized by the following formula:

A = f (x 1, x 2,…, x m), (3)

where x 1, x 2,…, x m results of direct measurements of quantities related by a known functional relationship f with the desired value of the measured quantity A .

Indirect measurements are typical for measurement practice in telecommunication systems, for example, measuring power using the ammeter-voltmeter method, determining the resonant frequency of an oscillating circuit based on the results of direct measurements of the capacitance and inductance of the circuit, determining the distance to the location of an inhomogeneity in an optical cable using the backscattering method, etc.

With cumulative measurementsseveral quantities of the same name are simultaneously measured, and their desired values are found by solving a system of equations obtained by direct measurements of various combinations of these quantities. For example, measurements in which the capacitance size of a set of capacitors is found from the known value of the capacitance of one capacitor and the results of direct comparisons of the capacitance sizes of various combinations of capacitors.

Joint measurementsconsist in the simultaneous measurement of two or more quantities of different names to find the relationship between them.

Example of joint measurements determination of the dependence of resistor resistance on temperature.

2 Classification of measurement methods

There are two main measurement methods:

- Direct assessment method, in which the size of the measured value is located on a scale, on a digital display or on the screen of a device, for example, measuring voltage with a voltmeter.

- Method of comparison with measure,in which the value of the measured quantity is compared with the value of the quantity reproduced by the measure. This method has the following varieties.

1) Contrasting method, in which the value of the quantities measured and reproduced by the measure influences the comparison device and with its help the relationship between these quantities is established.

2) Differential (difference) method , with it the measured value is determined by the difference between the desired value and the value reproduced by the measure.

3) Zero method a special case of differential, when the difference is brought to zero.

4) Substitution method the measured quantity is replaced by a measure equal in magnitude.

5) Match method- the value of the measured quantity is determined by the coincidence of signals, marks or other signs related to the measured and known quantities.

The substitution method and the zero method require the use of a multivalued measure.

This classification of measurement methods is illustrated in Fig. 1.

Picture 1

3. Basic measurement characteristics

The main characteristics of measurements are: result and error.

Result measurements of a physical quantity (briefly the result of a measurement or, simply the result) the value of a physical quantity obtained by measuring it.

Corrections are often made to the results obtained.

Amendment (English Correction) the value of a physical quantity of the same name as the one being measured, which is entered into the measurement result to exclude certain, so-calledsystematicerror components (see Chapter 2), which is reflected in the terminology:

- uncorrected measurement result measured value of a physical quantity obtained before corrections are made;

- corrected measurement result measured value of a physical quantity and clarified by introducing the necessary amendments to it;

Measuring instrument errorthe difference between the readings of the measuring instrument and the true value of the measured physical quantity.

Measurement qualitycharacterized by accuracy, correctness, convergence and reproducibility, reliability, as well as the size of permissible errors.Measurement qualitya set of properties that determine the receipt of results with the required accuracy characteristics, in the required form and within the established time frame.

Accuracy of measurement resultone of the characteristics of measurement quality, reflecting the closeness to zero error of the measurement result. High measurement accuracy corresponds to small errors. Accuracy is quantified by the reciprocal value of the relative error module, for example, if the relative error is 0.01, then the accuracy is 100.

Correct measurementscharacteristic reflecting the closeness to zero of systematic errors of measurement results.

Convergence of measurement resultscloseness to each other of the results of measurements of the same quantity, performed repeatedly by the same means, by the same method, under the same conditions and with the same care.

Reproducibilityproximity of measurement results of the same physical quantity, obtained in different places, by different methods and means, by different operators, at different times, but reduced to the same conditions (temperature, pressure, humidity, etc.).

Credibility characteristic of the quality of measurements, reflecting confidence in their results, which is determinedconfidence probabilityα that true value of the measured quantity A is in some given interval. Such an interval is called confidential and between its boundaries with a givenconfidence probability

(3)

the true value is found A the parameter being assessed. In (3) parameter q error significance level(see Chapter 2); , lower and upper limits of the confidence interval.

Literature

1. Lifits I.M. Fundamentals of standardization, metrology, certification. M.: Yurayt, 2011.

2. Sergeev A.G., Latyshev M.V., Teregerya V.V. Metrology. Standardization. Certification. M.: Logos, 2013.

3. Krylova G.D. Fundamentals of standardization, certification, metrology. M.: UNITY-DANA, 2013.

4. Lifits I.M. Standardization, metrology, certification. M.: Yurayt, 2013.

5. Basakov M.I. Certification of products and services with the basics of standardization and metrology. Rostov-on-Don, 2012.

Other similar works that may interest you.vshm> |

|||

| 6301. | Classification of technological indicators of catalysts. Basic technological characteristics of heterogeneous catalysts. Laboratory methods for their determination | 23.63 KB | |

| The position of the element in the Periodic Table, i.e. the structure of the electronic shells of atoms and ions ultimately determines all the basic chemical and a number of physical properties of a substance. Therefore, a comparison of the catalytic activity of solids with the position in the Periodic Table of the elements that form them led to the identification of a number of patterns in the selection of catalysts. | |||

| 8955. | Basic concepts related to measuring instruments | 2.38 MB | |

| Measuring instruments differ: according to their metrological purpose: operational and metrological; according to the design of measures, measuring instruments, measuring installations, measuring systems and measuring complexes; by level of automation into non-automatic, automated and automatic; according to the level of standardization into standard and non-standard; in relation to the measured value into main and auxiliary. Type of measuring instruments - a set of measuring instruments intended for measuring one... | |||

| 5904. | MAIN CHARACTERISTICS OF SIGNALS | 84.87 KB | |

| The emergence of the theory of electrical and radio circuits is inextricably linked with practice: with the formation of electrical engineering, radio engineering and radio electronics. Many domestic and foreign scientists contributed to the development of these areas and their theories. | |||

| 19099. | Culture, essence and main characteristics | 7.46 KB | |

| The term culture can characterize the culture of humanity in various countries, ethnic groups, social professional groups, or the culture of different eras, religious culture, Christian Islamic Buddhist. The word culture comes to us from the Latin cultur. Then the word culture began to be used in the non-material mental spiritual activity of a person. | |||

| 14730. | Basic characteristics of electrical signals | 179.62 KB | |

| Temporal and spectral representations of a periodic signal. A mathematical model of a signal is a system of mathematical relationships that describe the process or phenomenon being studied, a description of functions of distribution vectors, etc., using mathematical objects, which allows one to draw conclusions about the characteristics of the signal. The description of a signal of a certain time function completely determines its properties. | |||

| 6816. | Citizenship in the Russian Federation: main characteristics | 8 KB | |

| Citizen of the Russian Federation an individual who has Russian citizenship and has a document confirming his Russian citizenship. A foreign citizen in the Russian Federation is a person who does not have Russian citizenship but has confirmation of his citizenship of another state. A stateless person is a stateless person who is not a citizen of the Russian Federation and does not have proof of citizenship of a foreign state. The content of Russian Federation citizenship is the totality of mutual rights and obligations of the Russian Federation and a citizen of the Russian Federation. | |||

| 1584. | Concept and main characteristics of the foreign exchange market | 27.93 KB | |

| The object of study of this course work is the foreign exchange market. The subject of the study is the foreign exchange market in the process of implementing social relations. operation currency market exchange... | |||

| 21648. | Constitution of the USSR of 1924, main characteristics | 25.53 KB | |

| Development and adoption of the USSR Constitution of 1924. As we will see a little later, just during the formation of the USSR, the debate about whether a Constitution was needed or not had very serious practical grounds. Therefore, I believe that the goal of my work is to understand for myself how the Constitution of the USSR of 1924 was adopted, what were its features that distinguished it from other constitutions of the USSR. | |||

| 6787. | The concept and main characteristics of the constitutional system of Russia | 7.54 KB | |

| The constitutional system in a broad sense is a set of economic political social legal ideological social relations arising in connection with the organization of the highest authorities of the state structure, the relationship between man and the state, as well as civil society and the state... | |||

| 9085. | Technical means of information processing. Main characteristics of PC modules | 180.9 KB | |

| External memory of a personal computer Physical and logical structure of the disk Formatting the physical structure of the disk consists of creating concentric tracks on the disk, which in turn are divided into sectors. To do this, during the formatting process, the magnetic head of the drive places track and sector marks in certain places on the disk. The logical structure of a disk is a collection of sectors, each of which has its own serial number. When logically partitioning disks, the OS divides them into two parts: 1 System area... | |||

Measurement is the most important concept in metrology. This is an organized human action performed for quantitative knowledge of the properties of a physical object by empirically determining the value of any physical quantity.

There are several types of measurements. When classifying them, they usually proceed from the nature of the dependence of the measured quantity on time, the type of measurement equation, the conditions that determine the accuracy of the measurement result and the methods of expressing these results.

According to the nature of the dependence of the measured value on time, measurements are divided into:

static, in which the measured value remains constant over time;

dynamic, during which the measured value changes and is not constant over time.

Static measurements are, for example, measurements of body dimensions, constant pressure, dynamic measurements are measurements of pulsating pressures, vibrations.

Based on the number of measurements, they are divided into single and multiple. A single measurement is a measurement performed once. A multiple measurement is a measurement of a physical quantity of the same size, the result of which is obtained from several successive measurements, that is, consisting of a number of single measurements. Multiple measurements are performed in the case when the random component of the error of a single measurement may exceed the value required by the conditions of the problem. By performing a series of consecutive individual measurements, one multiple measurement is obtained, the error of which can be reduced by methods of mathematical statistics.

According to the method of obtaining measurement results, they are divided into:

indirect;

cumulative;

joint.

Direct measurements are those in which the desired value of a physical quantity is found directly from experimental data. Direct measurements can be expressed by the formula Q = X, where Q is the desired value of the measured quantity, and X is the value directly obtained from experimental data.

In direct measurements, the measured quantity is subjected to experimental operations, which is compared with the measure directly or using measuring instruments calibrated in the required units. Examples of direct measurements are measurements of body length with a ruler, mass using scales, etc. Direct measurements are widely used in mechanical engineering, as well as in the control of technological processes (measuring pressure, temperature).

Indirect are measurements in which the desired quantity is determined on the basis of a known relationship between this quantity and the quantities subjected to direct measurements, i.e. They measure not the actual quantity being determined, but others that are functionally related to it. The value of the measured quantity is found by calculating using the formula Q = F(x 1,x 2,...,x n), where Q is the desired value of the indirectly measured quantity; F is a functional dependence that is known in advance, x 1,x 2,...,x n are the values of quantities measured directly.

Cumulative are measurements of several quantities of the same name made simultaneously, in which the desired one is determined by solving a system of equations obtained by direct measurements of various combinations of these quantities.

Joint measurements are measurements of two or more different quantities taken simultaneously to find dependencies between them.

According to the conditions that determine the accuracy of the result, measurements are divided into three classes:

measuring the highest possible accuracy achievable with the current level of technology. This class also includes some special measurements that require high accuracy;

control and verification measurements, the error of which, with a certain probability, should not exceed a certain specified value;

technical measurements in which the error of the result is determined by the characteristics of the measuring instruments.

According to the method of expressing measurement results, a distinction is made between absolute and relative measurements.

Absolute measurements are those that are based on direct measurements of one or more basic quantities or on the use of the values of physical constants.

Relative are measurements of the ratio of a quantity to a quantity of the same name, which plays the role of a unit, or measurements of a quantity in relation to a quantity of the same name, taken as the initial one.

There are other classifications of measurements, for example, by connection with the object (contact and non-contact), by measurement conditions (equally accurate and unequally accurate).

The main characteristics of measurements are: measurement principle, measurement method, error, accuracy, correctness and reliability.

Measuring principle– a physical phenomenon or a set of physical phenomena underlying measurements. For example, measuring body weight using weighing using gravity proportional to mass, measuring temperature using the thermoelectric effect.

Currently, all measurements, in accordance with the physical laws used in their implementation, are grouped into 13 types of measurements. In accordance with the classification, they were assigned two-digit codes for the types of measurements: geometric (27), mechanical (28), flow, capacity, level (29), pressure and vacuum (30), physicochemical (31), temperature and thermophysical (32 ), time and frequency (33), electrical and magnetic (34), radioelectronic (35), vibroacoustic (36), optical (37), parameters of ionizing radiation (38), biomedical (39).

Measurement method– a set of techniques for using principles and measuring instruments.

Measurement method– a technique or set of techniques for comparing a measured quantity with its unit in accordance with the implemented measurement principle. As a rule, the measurement method is determined by the design of the measuring instruments. Measuring instruments are the technical means used that have standardized metrological properties. Examples of common measurement methods are the following:

direct assessment method - a method in which the value of a quantity is determined directly from the indicating measuring instrument. For example, weighing on a dial scale or measuring pressure with a spring pressure gauge;

differential method - a measurement method in which the measured quantity is compared with a homogeneous quantity having a known value that differs slightly from the value of the measured quantity, and in which the difference between these two quantities is measured. This method can give very accurate results. So, if the difference is 0.1% of the measured value and is estimated by the device with an accuracy of 1%, then the accuracy of measuring the desired value will be 0.001%. For example, when comparing identical linear measures, where the difference between them is determined by an ocular micrometer, which allows it to be estimated to tenths of a micron;

zero measurement method - a method of comparison with a measure, in which the resulting effect of the influence of the measured quantity and measure on the comparison device is brought to zero. A measure is a means of measurement designed to reproduce and store a physical quantity. For example, measuring mass on an equal-arm scale using weights. It is one of the very precise methods.

method of comparison with a measure - a measurement method in which the measured value is compared with the value reproduced by the measure. For example, measuring the DC voltage on a compensator by comparison with the known EMF of a normal element. The measurement result with this method is either calculated as the sum of the value of the measure used for comparison and the reading of the measuring device, or is taken equal to the value of the measure. There are various modifications of this method: the method of measurement by substitution (the measured quantity is replaced by a measure with a known value of the quantity, for example, when weighing by alternately placing mass and weights on the same pan of scales) and the method of measurement by addition (the value of the measured measure is supplemented by a measure of the same quantity with such a calculation that the comparison device is affected by their sum equal to a predetermined value).

The quality of measurements is characterized by accuracy, reliability, correctness, convergence and reproducibility of measurements, as well as the size of the error.

Measurement error– the difference between the value obtained during measurement and the true value of the measured quantity. The error is caused by the imperfection of measurement methods and instruments, the variability of observation conditions, as well as the insufficient experience of the observer or the characteristics of his senses.

Accuracy of measurements is a characteristic of measurements that reflects the closeness of their results to the true value of the measured value. Quantitatively, accuracy can be expressed as the reciprocal of the modulus of the relative error.

Correct measurement is defined as the quality of measurement, reflecting the closeness to zero of systematic errors in the results (i.e., such errors that remain constant or naturally change with repeated measurements of the same quantity). The accuracy of measurements depends, in particular, on how much the actual size of the unit in which the measurement is made differs from its true size (by definition), i.e. on the extent to which the measuring instruments used for a given type of measurement were correct (correct).

The most important characteristic of the quality of measurements is their reliability. It characterizes the confidence in measurement results and divides them into two categories: reliable and unreliable, depending on whether the probabilistic characteristics of their deviations from the true values of the corresponding quantities are known or unknown. Measurement results whose reliability is unknown are of no value and in some cases can serve as a source of misinformation.

Convergence(repeatability) is the quality of measurements, reflecting the closeness to each other of the results of measurements of the same parameter, performed repeatedly with the same measuring instruments, by the same method under the same conditions and with the same care.

Reproducibility– this is the quality of measurements, reflecting the closeness to each other of the results of measurements of the same parameter, performed under different conditions (at different times, by different means, etc.).

As noted above, measurement is the process of experimentally obtaining one or more values of a quantity that can be reasonably assigned to it. The value of the measured quantity depends on the measurement conditions, the chosen method, the type of measuring instrument, etc.

Main measurement characteristics include measurement principles, measurement methods, and measurement accuracy.

The measurement principle is a physical phenomenon (effect) that forms the basis for measurements using one or another type of measuring instrument.

A large number of physical effects discovered by scientists during research are used as measurement principles. For example, using the Doppler effect to measure speed; application of the Hall effect to measure magnetic field induction; the use of gravity in measuring mass by weighing.

Examples of the application of different measurement principles are the piezoelectric effect, thermoelectric effect and photoelectric effect.

Piezoelectric effect consists in the occurrence of EMF on the surface (faces) of some crystals (quartz, tourmaline, artificial piezoelectric materials) under the influence of external forces. Quartz and piezoceramics (for example, barium titanate), which have fairly high mechanical strength and temperature stability (quartz up to a temperature of 200°C; piezoceramics - up to 115°C), have found the greatest application for measurements.

Piezoelectric effect reversible: an emf applied to a piezoelectric crystal causes mechanical stress on its surface. Measuring transducers based on the piezoelectric effect are self-generating for dynamic measurements.

Thermoelectric effect used for temperature measurements, and two main ways to realize this effect are used.

In the first case, the property of changing the electrical resistance of metals and semiconductors with temperature changes is used. The metals often used are copper (for routine measurements) and platinum (for high-precision measurements). The corresponding measuring transducer is called a thermistor. The sensitive elements of a semiconductor converter - a thermistor - are made from oxides of various metals. As the temperature increases, the resistance of the thermistor decreases, while that of the thermistor increases. The dependence of the resistance of thermistors with temperature changes is nonlinear; for copper thermistors it is linear; for platinum thermistors it is approximated by a square trinomial.

Platinum thermistors allow you to measure temperatures in the range from -200°C to +1000°C.

For measurement purposes, external and internal photoelectric effects are used. The external photoelectric effect occurs in an evacuated cylinder having an anode and a photocathode. When the photocathode is illuminated, electrons are emitted under the influence of light photons. When there is an electrical voltage between the anode and the photocathode, the electrons emitted by the photocathode form an electric current called photocurrent.

In this way, light energy is converted into electrical energy.

Method of measurement– this is a set of techniques (methods) used to compare the measured quantity with its unit (or scale) in accordance with the selected measurement principle.

Measurement methods are divided into methods of direct assessment and methods of comparison with a measure. Methods of comparison with a measure are divided into contrast, differential, zero, substitution and coincidence methods.

Direct assessment method consists in determining the value of a physical quantity using the reading device of a direct-acting measuring device. For example, measuring voltage with a voltmeter. This method is the most common, but its accuracy depends on the accuracy of the measuring instrument.

Comparison method with measure uses a comparison of the measured value with the value reproduced by the measure. The measurement accuracy may be higher than the accuracy of direct assessment.

Contrasting method is based on the simultaneous influence of the measured and reproducible quantity on a comparison device, with the help of which the relationship between quantities is established. For example, measuring weight using a lever scale and a set of weights.

When differential method the measuring device is affected by the difference between the measured quantity and the known quantity reproduced by the measure. In this case, the balancing of the measured value with a known one is not carried out completely. For example, measuring DC voltage using a discrete voltage divider, a reference voltage source, and a voltmeter.

Using null method the resulting effect of the influence of both quantities on the comparison device is brought to zero, which is recorded by a highly sensitive device - a zero indicator. For example, measuring the resistance of a resistor using a four-arm bridge, in which the voltage drop across a resistor of unknown resistance is balanced by the voltage drop across a resistor of known resistance.

Substitution method is based on alternately connecting the measured quantity and a known quantity to the input of the device, and based on the two readings of the device, the value of the measured quantity is estimated, and then by selecting a known quantity, it is ensured that both readings coincide.

With this method, high measurement accuracy can be achieved with a high precision measure of a known quantity and high sensitivity of the device. For example, the accurate measurement of a small voltage using a highly sensitive galvanometer, to which a source of unknown voltage is first connected and the deflection of the pointer is determined, and then using an adjustable source of known voltage, the same deflection of the pointer is achieved. In this case, the known voltage is equal to the unknown.

By coincidence method determine the difference between the measured value and the value reproduced by the measure, using the coincidence of scale marks or periodic signals. For example, measuring the rotation speed of a part using a flashing strobe lamp: observing the position of the mark on the rotating part at the moments of the lamp flashes, the speed of the part is determined from the known frequency of the flashes and the displacement of the mark.

Verification of compliance with mandatory requirements and rules is carried out in the manner of state control (supervision) over compliance with mandatory requirements.

Accuracy of measurements is determined by the closeness to zero of the measurement error, i.e. closeness of measurement results to the true value of a quantity.

True value of the measured quantity– the value of a physical quantity that would ideally reflect the corresponding property of an object in quantitative and qualitative terms.

The actual value of the measured quantity is a value found experimentally that is so close to the true value that it can be used instead for a given purpose.

Due to the characteristics of our sense organs (vision and hearing) and the imperfection of the measuring instruments we use, it is impossible to determine the true value of the measured value.

One can only indicate that it is between some two values, one of which is taken with a deficiency, and the other with an excess. The closer these values are to each other, the smaller their difference, the more accurate the measurement is, therefore.

The measurement error can be quantitatively expressed in units of the measured value or in relation to the error to the measurement result, but the accuracy of measurements cannot be determined directly from the measurement results. Therefore, they usually talk about high (medium, low) measurement accuracy in a qualitative sense.

That is why it is more convenient to quantify the accuracy of measurements using an error.

Thus, the experimenter’s task is not only to determine this or that desired value, but also to indicate what is the accuracy of determining this value, or, in other words, what is the value of the error allowed.

The following main measurement characteristics are distinguished:

1) the method by which measurements are taken;

2) measurement principle;

3) measurement error;

4) measurement accuracy;

5) correctness of measurements;

6) reliability of measurements.

Measurement method- this is a method or a set of methods by which a given quantity is measured, i.e., a comparison of the measured quantity with its measure according to the accepted principle of measurement.

There are several criteria for classifying measurement methods.

1. According to the methods of obtaining the desired value of the measured quantity, the following are distinguished:

1) direct method (carried out using direct, direct measurements);

2) indirect method.

2. According to measurement techniques, there are:

1) contact measurement method;

2) non-contact measurement method.

Contact measurement method based on direct contact of any part of the measuring device with the measured object.

At non-contact measurement method the measuring device does not come into direct contact with the object being measured.

3. According to the methods of comparing a quantity with its measure, the following are distinguished:

1) direct assessment method;

2) method of comparison with its unit.

Direct assessment method is based on the use of a measuring device that shows the value of the measured quantity.

Comparison method with measure based on comparing the object of measurement with its measure.

Measuring principle– this is a certain physical phenomenon or their complex on which the measurement is based.

Measurement error is the difference between the result of measuring a quantity and the real (actual) value of this quantity.

Accuracy of measurements– this is a characteristic that expresses the degree of correspondence of the measurement results to the real value of the measured quantity.

Correct measurement– this is a qualitative characteristic of a measurement, which is determined by how close to zero the value of a constant or fixed error that changes during repeated measurements (systematic error).

Reliability of measurements is a characteristic that determines the degree of confidence in the obtained measurement results.

4 The concept of physical quantity The meaning of systems of physical units

A physical quantity is a concept of at least two sciences: physics and metrology. By definition, a physical quantity is a certain property of an object or process, common to a number of objects in terms of qualitative parameters, but differing, however, in quantitative terms (individual for each object). There are a number of classifications created according to various criteria. The main ones are divided into:

1) active and passive physical quantities – when divided in relation to measurement information signals. Moreover, the first (active) in this case are quantities that, without the use of auxiliary energy sources, have the probability of being converted into a measurement information signal. And the second (passive) are quantities for which it is necessary to use auxiliary energy sources that create a signal of measurement information;

2) additive (or extensive) and non-additive (or intensive) physical quantities - when dividing on the basis of additivity. It is believed that the first (additive) quantities are measured in parts; in addition, they can be accurately reproduced using a multivalued measure based on the summation of the sizes of individual measures. But the second (non-additive) quantities are not directly measured, since they are converted into a direct measurement of a quantity or a measurement by indirect measurements. In 1791, the first ever system of units of physical quantities was adopted by the French National Assembly. It was a metric system of measures. It included: units of length, area, volume, capacity and weight. And they were based on two now well-known units: the meter and the kilogram.

The scientist based his methodology on three main independent quantities: mass, length, time. And the mathematician took the milligram, millimeter and second as the main units of measurement for these quantities, since all other units of measurement can be easily calculated using the minimum ones. Thus, at the present stage of development, the following main systems of units of physical quantities are distinguished:

1) GHS system(1881);

2) MKGSS system(late 19th century);

3) MKSA system(1901)

Before understanding the essence of any phenomena, it is convenient to first organize them, i.e. classify.

Dimensions are divided into types of measurements- part of the measurement area,

having its own characteristics and characterized by the homogeneity of the measured values, and measurement methods- part of the measurement field, consisting in the difference in methods of using principles and measuring instruments.

- Classification of types of measurements

Classification of types of measurements can be carried out according to various classification criteria, which include the following: the method of finding the numerical value of a physical quantity, the number of observations, the nature of the dependence of the measured quantity on time, the number of measured instantaneous values in a given time interval, the conditions determining the accuracy of the results, the method of expression measurement results (Fig. 2.1).

By method of finding the numerical value of a physical quantity measurements are divided into the following types: direct, indirect, cumulative and joint.

Direct measurement called a measurement in which the value of the measured physical quantity is found directly from experimental data. Direct measurements are characterized by the fact that an experiment as a measurement process is carried out on the measured quantity itself, meaning this or that

its other manifestation. Direct measurements are performed using tools designed to measure these quantities. The numerical value of the measured quantity is calculated directly from the reading of the measuring device. means, quantities. Examples of direct measurements: current measurement with an ammeter; voltage - compensator; mass - on lever scales, etc.

The relationship between the measured value X and the measurement result Y during direct measurement is characterized by the equation X = Y, i.e. the value of the measured quantity is assumed to be equal to the result obtained.

Unfortunately, direct measurement is not always possible. Sometimes the appropriate measuring instrument is not at hand, or it is unsatisfactory.

in accuracy, or even not yet created at all. In this case, you have to resort to indirect measurement.

Indirect measurements These are measurements in which the value of the desired quantity is found on the basis of a known relationship between this quantity and the quantities subjected to direct measurements. In indirect measurements, it is not the actual quantity being determined that is measured, but other quantities that are functionally related to it. The value of the quantity measured indirectly X found by calculation using the formula

X =

F(Y1

,

Y2

, … ,

Yn),

Where Y1, Y2, …Yn- values of quantities obtained by direct measurements.

An example of an indirect measurement is the determination of electrical resistance using an ammeter and a voltmeter. Here, by direct measurements, the voltage drop values are found U on resistance R and current I through it, and the desired resistance R is found by the formula

R =

U/

I .

The operation of calculating the measured value can be performed manually or using a computing device placed in the device.

Direct and indirect measurements are currently widely used in practice and are the most common types of measurements.

Aggregate Measurements- these are measurements of several quantities of the same name made simultaneously, in which the desired values of the quantities are found by solving a system of equations obtained by direct measurements of various combinations of these quantities.  For example, to determine the resistance values of resistors connected by a triangle (Fig. 2.2), measure the resistance at each

For example, to determine the resistance values of resistors connected by a triangle (Fig. 2.2), measure the resistance at each

pair of vertices of a triangle and get a system of equations  ;

; ;

; .

.

From the solution of this system of equations the resistance values are obtained

,

,  ,

,  ,

,

Where .

Joint measurements- these are measurements of two or more different quantities made simultaneously X1, X2,…,Xn, the values of which are found by solving the system of equations:

Fi(X1, X2, … ,Xn; Yi1, Yi2, … ,Yim) = 0,

Where i = 1, 2, …, m>

n; Yi1, Yi2, … ,Yim- results of direct or indirect measurements; X1, X2, … ,Xn- values of the required quantities.

For example, the inductance of the coil L = L0×

(1 +

w2

×

C×

L0), Where L0- inductance at frequency w = 2

×

p×

f tending to zero; C - interturn capacitance. Values L0 And WITH cannot be found by direct or indirect measurements. Therefore, in the simplest case we measure L1 at w1

, and then L2 at w2

and form a system of equations:

L1 = L0×

(1 +

w1

2

×

C×

L0);

L2 = L0×

(1 +

w2

2

×

C×

L0),

solving which, we find the required inductance values L0 and containers WITH: ;

;  .

.

Cumulative and joint measurements are a generalization of indirect measurements to the case of several quantities.

To increase the accuracy of aggregate and joint measurements, the condition m ³ n is provided, i.e. the number of equations must be greater than or equal to the number of required quantities. The resulting inconsistent system of equations is solved by the least squares method.

By number of measurement observations are divided into (Fig. 2.1):

- ordinary measurements - measurements performed with a single observation;

- statistical measurements - measurements with multiple observations.

Observation during measurement is an experimental operation performed during the measurement process, as a result of which one value is obtained from a group of values of quantities that are subject to joint processing to obtain measurement results.

The result of an observation is the result of a quantity obtained from a separate observation.

By the nature of the dependence of the measured quantity on time dimensions are divided:

- static, in which the measured value remains constant over time during the measurement process;

- dynamic, in which the measured value changes during the measurement process and is not constant over time.

In dynamic measurements, this change must be taken into account to obtain the measurement result. And to assess the accuracy of the results of dynamic measurements, knowledge of the dynamic properties of measuring instruments is necessary.

By number of measured instantaneous values in a given time interval measurements are divided into discrete And continuous(analog).

Discrete measurements are measurements in which, over a given time interval, the number of measured instantaneous values is finite.

Continuous (analog) measurements are measurements in which, over a given time interval, the number of measured instantaneous values is infinite.

According to the conditions determining the accuracy of the results, measurements are:

- the highest possible accuracy achieved with the existing level of technology;

- control and verification tests, the error of which should not exceed

some given value;

- technical, in which the error of the result is determined by the characteristics of the measuring instruments.

According to the method of expressing measurement results distinguish between absolute and relative measurements.

Absolute measurements- measurements based on direct measurements of one or more basic quantities and (or) use of the values of physical constants.

Relative measurements- measuring the ratio of a quantity to a quantity of the same name, which plays the role of a unit, or measuring a quantity in relation to a quantity of the same name, taken as the initial one.

2.2. Measurement methods and their classification

All measurements can be made using various methods. The following main measurement methods are distinguished: direct assessment method And comparison methodscmeasure .

2.2.1. Direct assessment method characterized by the fact that the value of the measured quantity is determined directly from the reading device of the measuring device, previously calibrated in units of the measured quantity. This method is the simplest and therefore is widely used in measuring various quantities, for example: measuring body weight on a spring scale, electric current with a dial ammeter, phase difference with a digital phase meter, etc.

The functional diagram of measurement using the direct assessment method is shown in Fig. 2.3.

Direct assessment devices always contain a measuring transducer, which converts the measured value into another, available for comparison by an observer or an automatic device. Thus, in pointer instruments, the measured value is converted into the angle of rotation of the moving part, which is marked by an arrow. According to the position of the arrow, i.e. By comparing the angle of rotation with the divisions on the scale, the value of the measured quantity is found. The measure in direct assessment instruments is the division of the scale of the reading device. They are not placed arbitrarily, but based on the calibration of the device. The calibration of a direct assessment device consists in the fact that a value of a given size is supplied to its input from a measure and the reading of the device is noted. This reading is then assigned the value of a known quantity. Thus, the divisions of the scale of the reading device are, as it were, a substitute (“fingerprint”) for the value of a real physical quantity and therefore can be used directly to find the values of quantities measured by the device. Consequently, all direct assessment devices actually implement the principle of comparison with physical quantities. But this comparison is multi-temporal and is carried out indirectly, using an intermediate means - divisions of the scale of the reading device.

2.2.2. Methods of comparison with a measure - measurement methods in which a known quantity is compared with a value reproduced by a measure. These methods are more accurate than the direct assessment method, but are somewhat complex. The group of methods for comparison with a measure includes the following methods: opposition, zero, differential, coincidence and substitution.

Defining characteristic comparison methods is that in the process of each measuring experiment there is a comparison of two homogeneous quantities independent of each other - the known (reproducible measure) and the measured one. When measuring by comparison methods, real physical measures are used, and not their “prints”.

Comparison can be simultaneous when the measure and the quantity being measured act on the measuring device simultaneously, and multi-temporal, when the impact of the measured quantity and the measure on the measuring device is separated in time. In addition, comparison can be direct And indirect. In the first case, the measured quantity and measure directly affect the comparison device, and in the second - through other quantities that are uniquely related to the known and measured quantities.

Simultaneous comparison is usually carried out using methods oppositions, zero, differential And coincidences, and multi-temporal - method substitution.

Contrasting method- a method of comparison with a measure in which the measured quantity and the quantity reproduced by the measure simultaneously influence a comparison device, with the help of which the relationship between these quantities is established. The functional diagram of the opposition method is shown in Fig. 2.4.

In this method, the measured quantity X and the measure X0 act on two inputs of the comparison device. The resulting impact effect is determined by the difference between these values, i.e. e = X - X0 and is removed from the reading device of the comparison device. The measurement result is found as

Y = X0 + e.

This method is convenient if there is an exact multivalued measure and simple

comparison devices. An example of this method is weighing a load on an equal-arm scale, placing the measured mass and the weights balancing it on two scales and completely balancing the scales. In this case, the measured mass is defined as the sum of the mass of the weights that balance it, and the readings on the scale. The contrast method makes it possible to significantly reduce the impact of influencing quantities on the measurement result, since the latter more or less equally distort the signals both in the conversion circuit of the measured quantity and in the conversion chain of the quantity reproduced by the measure. The reading device of the comparison device reacts to the difference in signals, as a result of which these distortions compensate each other to some extent. This method is also used in measuring EMF, voltage, current and resistance.

Null method is a type of contrast method in which the resulting effect of the influence of quantities on a comparison device is brought to zero. The functional diagram of the zero measurement method is shown in Fig. 2.5.

Here the measured quantity X and the measure X0 act on the two inputs of the comparison measuring device. The resulting impact effect is determined by the difference between these values, i.e. e = X - X0. By changing the value reproduced by the measure (this is schematically indicated in the figure by an arrow), you can bring the value of e to 0. This circumstance is indicated by a zero indicator. If e = 0, then X = Xo, the result of measuring Y is the obtained value  measures, i.e. Y = X0.

measures, i.e. Y = X0.

Since the zero indicator is affected by the difference in values, its measurement limit can be chosen smaller and its sensitivity greater than that of the device for measuring X by the direct assessment method. The accuracy of indicating the equality of two quantities can be very high. And this leads to increased measurement accuracy. The error of measurement using the zero method is determined by the error of the measure and the error of the zero indication. The second component is usually much smaller than the first; practically, the accuracy of measurement using the zero method is equal to the accuracy of the measure.

Examples of zero measurement methods are: measuring mass on an equal-arm scale with placing the measured mass and weights balancing it on two scales and completely balancing the scales, or measuring voltage by compensating it with the voltage of a reference source (in both cases a direct comparison is made); as well as measuring the electrical resistance of the bridge with its complete balancing (indirect comparison).

The zero measurement method requires the mandatory use of multivalued measures. The accuracy of such measures is always worse than unambiguous measures, in addition, we may not have a variable measure. In this case, the null method is not applicable.

Differential method is a method of comparison with a measure, in which a measuring device (necessarily a comparison device) is affected by the difference between the measured value and a known value reproduced by the measure, and this difference is not brought to zero, but is measured by a direct-acting measuring device.

In Fig. Figure 2.6 shows the functional diagram of the differential method.

Here the measure has a constant value X0, the difference between the measured value X and the measure X0, i.e. e = X - X0, is not zero and is measured by a measuring device. The measurement result is found as

Y = X0 + e.

The fact that here the measuring device does not measure the entire value X, but only part of it e, makes it possible to reduce the influence of the measuring device error on the measurement result, and the smaller the difference e, the smaller the influence of the measuring device error.

Indeed, when measuring a voltage U = 97 V with a direct assessment voltmeter with a measurement limit of 100 V and an assumed relative measurement error of this voltage of 1% (0.01), we obtain an absolute measurement error D1 = 97 × 0.01 = 0.97 » 1 V If we measure this voltage by the differential method using a reference voltage source U0 = 100 V, then the voltage difference U - U0 = (97 - 100)V = - 3 V we can measure with a voltmeter with a measurement limit of only 3 V. Let the relative error measuring this voltage will also be equal to 1%. This gives an absolute voltage measurement error of 3 V: D2 = 3 × 0.01 = 0.03 V. If this error is reduced to the measured voltage U, we obtain a relative voltage measurement error: D2/U = 0.03/97 » 0, 0003 (0.03%), i.e. approximately 30 times less than when measuring voltage U using the direct estimation method. This increase in measurement accuracy occurred because in the first case, the device measured almost the entire value with a relative error of 1%, and in the second case, not the entire value was measured, but only 1/30 of it.

These calculations did not take into account the error of the measure, which is fully included in the measurement result. Consequently, for small difference values e, the measurement accuracy by the differential method approaches the measurement accuracy by the zero method and is determined only by the error of the measure. In addition, the differential method does not require a measure of a variable quantity.

In the differential voltage measurement example above, a direct comparison was used.

Another example of a differential measurement method is the determination of the deviation of the resistor resistance from the nominal value by an unbalanced (percentage) bridge (an indirect comparison is implemented here).

Match method(or vernier method) is a method of comparison with a measure in which the difference between the measured quantity and the value reproduced by the measure is measured using the coincidence of scale marks or periodic signals.

This method is used in cases where the measured quantity is less than the division value of a given measure. In this case, two measures are used with different division prices, which differ by the size of the estimated digit of samples.

Let us have one calibrated measure with division price Dxk1 and measured value Dx, which is less than the division price. In this case, use the second measure with division price Dxk2. Thus, if the sensitivity needs to be increased by P times, then the relationship between them will have the form

Dxk2 =Dxk1×( 1 -

1/

n).

In particular, when n = 10 Dxk2 =0.9×

Dxk1.

Measured quantity Dx set between the zero marks of the measures and find the number Nx, equal to the number of coincident divisions of measures (Fig. 2.7). In this case the relation is valid Nx×

Dxk1 =Dx+Nx×

Dxk2, where

Dx = Nx×(Dxk1 - Dxk2) = Nx×(Dxk1 - 0.9×Dxk1) = Nx×0.1×Dxk1.

An example of a coincidence measurement is measuring the length of a part using a vernier caliper; another example is measuring the rotation speed of a part using a flashing strobe lamp: observing the position of the mark on the rotating part when the lamp flashes, the speed of the part is determined by the frequency of the flashes and the displacement of the mark. The vernier method is also widely used in measuring time intervals of two close frequencies (beats) and in other cases.

The functional diagram of a device operating using the coincidence method with scaling transformation of only the value reproduced by the measure is shown in Fig. 2.8. Here, the value X0 of a single-valued measure is subjected to a scale transformation to produce the values n1X0, n2X0, … njX0, … nkX0. These values are supplied to k-comparison devices, and the measured value X is also applied to them. The logical device indicates the number of the comparison device for which X is njX0 = min and determines the measured value based on the approximate relation X = njX0. This measurement method has also found application in digital instruments that measure angular and linear displacements. The coincidence method requires the presence of multivalued measures or scale converters of magnitude and magnitude reproduced by the measure. Therefore, it is used relatively rarely in measuring technology.

Substitution method there is a method of comparison with a measure, in which the measured quantity is replaced by a known quantity reproduced by the measure.

The functional diagram of the substitution method is shown in Fig. 2.9. It uses a direct evaluation measuring instrument.  The measurement technique is as follows. First, the measured value X is supplied to the input of the measuring device and the readings of the device (reading) Y1 are noted. After this, instead of the measured value by the same

The measurement technique is as follows. First, the measured value X is supplied to the input of the measuring device and the readings of the device (reading) Y1 are noted. After this, instead of the measured value by the same

The input (this is very important) of the device is supplied with the value X0, reproduced by the measure. In this case, the instrument reading becomes equal to Y2. By changing the value reproduced by the measure, equality of readings is achieved, i.e. Y1=Y2. In this case, it can be argued that X = X0, regardless of the error of the measuring device. Indeed, in the first case we obtain Y1= X + D1,

where D1 is the error of the measuring device when receiving the reading Y1.

When the device is exposed to a measure Y2= X + D2. Here D2 is the error of the measuring device when receiving the reading Y2.

Since we achieve the same readings (Y1 = Y2), and the time interval between two measurements is small, then at the same mark on the instrument scale the error is the same, i.e. D1 = D2. Consequently, from the equality Y1 = Y2 or X + D1 = X + D2 it follows that X = X0.

The exclusion of the measuring instrument error from the measurement result is a new advantage of the substitution method. In the zero measurement method, the error of the measuring device manifests itself in that the zero reading may not correspond to the equality of the measured value and the measure, and in the differential method it represents the error in measuring the difference between the measure and the measured value. To obtain high measurement accuracy using the zero and differential method, it is necessary that the errors of the measuring instruments be small. But the replacement method does not require this condition! Even if the error of the measuring device is large enough, this will not affect the measurement result. Thus, using the substitution method, it is possible to carry out an accurate measurement, having a device with a large error. It is not difficult to understand that the accuracy of measurement by the substitution method is determined by the error of the measure. True, with a more strict approach to the substitution method, two circumstances should be taken into account.

Firstly, here the comparison is made at different times, and during the time between two measurements the error of the measuring device may change slightly, so that the equality D1 = D2 is somewhat violated. Now it becomes clear why the measured quantity and the measure must be supplied to the same input of the device. This is primarily due to the fact that the error of the measuring device at different inputs, even with the same readings, can be different!

Secondly, the substitution method comes down to obtaining identical instrument readings. The equality of indications itself can be established with finite accuracy. And this also leads to measurement error. The accuracy of establishing equality of readings will be greater in a device with greater sensitivity.

Therefore, when measuring by the substitution method, you should use a device that is not accurate, but sensitive and fast-acting. Then the residual error caused by the measuring device will be small.

The substitution method is the most accurate of all known methods and is usually used to make the most accurate (precision) measurements. A striking example of the substitution method is weighing with alternately placing the measured mass and weights on the same pan of scales (remember - at the same input of the device). It is known that using this method you can correctly measure body weight if you have incorrect scales (instrument error), but not weights! (measure error).

Comparing the substitution method and the direct assessment method, we will discover their striking similarities. Indeed, the direct assessment method is essentially a substitution method. Why is it separated into a separate method? The thing is that when measuring using the direct assessment method, we perform only the first operation - determining the readings. The second operation - calibration (comparison with a measure) is not performed with every measurement, but only during the production process of the device and its periodic verification. There may be a large time interval between the use of the instrument and its previous verification, and the error of the measuring instrument may change significantly during this time. This leads to the fact that the direct assessment method usually gives less measurement accuracy than the comparison method.

The considered classification of measurement methods is shown in Fig. 2.10.

Rice. 2.10. Classification of measurement methods

The considered methods determine the principles of constructing measuring instruments. They should not be confused with measurement technique and measurement algorithm.

Measurement technique- a detailed procedure for the measurement process, regulating methods, means, and algorithms for performing measurements, which, under certain (standardized) conditions, provide measurements with a given accuracy.

Measurements must be carried out in accordance with duly certified methods. The procedure for the development and certification of measurement methods is determined by the State Standard of Russia.

Measurement algorithm- a precise instruction to perform in a certain order a set of operations that ensure the measurement of the value of a physical quantity.

.