Russian anchors. Domestic anchors-monuments The city where the best Russian anchors were made

There have always been informal symbols and signs that reflected the traditions, customs and characteristics of the Votkinsk residents, it is not for nothing that the people say: “Whatever the city, then the burrows!”. As a result of a sociological survey among the employees of the Museum of History and Culture of Votkinsk and visitors, the “MAGNIFICENT SEVEN” of the most significant signs was compiled, which reflect the essence of the concept of “our, indigenous Votkinsk ...”.

1. Plant, dam- our city, its glory began with them, ours was forged and tempered here special "Votkinsky character".

2. Cathedral of the Annunciation- the spiritual symbol of the city, which is reborn again.

3. Museum-estate of P.I. Tchaikovsky– we are proud to be countrymen of the greatRussian composer.

4. A typical house of the Votkinsk craftsman- solid, two-story, with large windows,light "terrace", with a front porch and a front garden in which high mallows bloom,and in the spring, the “lilac boil” captivates - all this pleases not only the eye, but also the soul! Close to home -a large garden where many bushes of currants, gooseberries grow, apple trees and cherries bear fruit.Limes, elms, larches are sure to be planted in front of the house, creating comfort and coolness in the heat,a sense of security and unity with nature, which was so valued in the old Votkinsk.

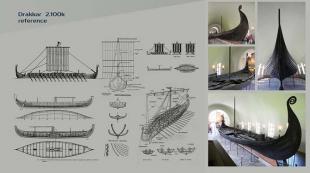

5. Anchor- a symbol of hope since ancient times. The Votkinsk plant produced the best Russiananchors. This marine symbol is found in the decoration of architraves, it was made in the form of an originalcandlesticks, women wore elegant pendants in the form of anchors, etc.

6. Chebak- the main fish of our city. Traditionally, both old and young in Votkinsk are fond of fishing,they love not only catching fish, but also cooking a wonderful fish pie. No wonder they called Votkintsyold nickname - "CHEBAKI".

7. And, of course, our pond- a source of strength and power, beauty and inspiration. It's always different:sometimes sad and pensive, sometimes stormy and restless, sometimes poetically inspired... Like mightygiants guard its shores with hundred-year-old pines and spruces. Once upon a time our pond was called Lebedin, onon its water surface one could see proud birds that felt safe here ...Young Pyotr Tchaikovsky, and Evgeny Vissov, the future writer, did not get tired of admiring its beauties, andthousands and thousands of our countrymen, whose work, perseverance, "the glory of our land grew."

It is not clear what is translated from an unknown language, I tried to put together all the impressions that I took out of the small Udmurt town of Votkinsk. Tried and tried and gave up: don't mix things up. So the first thing is just a "sightseeing tour", well ... very overview ...

It stands all along the banks of the Votkinsky Pond, unique, gigantic, I would say. 19 square kilometers, dug by hand for the construction of a dam, on the energy of falling water from which in 1759 the ironworks set up here by Count Shuvalov started working.

The history of the plant, in a good way, deserves a separate story, if only out of respect for the enterprise, which began with the forging of anchors, and then within its walls produced steamships, steam locomotives, the first Soviet excavators and ballistic missiles. Oil and gas equipment, machine tools, household appliances - who said that the Russian industry is dead? Did she die after all?) Well, Topol-M and Bulava also gather here, in an inconspicuous town far from the main roads.

Every single one of St. Petersburg residents and guests of the northern capital is well acquainted with the work of factory artisans, even if they don’t know about it: it was they who made and installed the spire of the Peter and Paul Cathedral. When the question of the spire arose, the emperor was informed that it could only be made in England or at the Votkinsk plant, and the Russian craftsmen took half as much for the work as the British specialists had asked for.

Votkintsy will definitely show you the spire of their Annunciation Cathedral, hinting - it looks like it, doesn't it?

A legend is connected with the founding of the church at this very place, which develops the motive of opposition between paganism and Orthodoxy, traditional for the Vyatka, Udmurt region. The legend was told by the archpriest of the Annunciation Cathedral A.I. Chernishevsky: “On the hill where the Cathedral of the Annunciation, they (the Votyaks) had a tent, i.e. a strong barn with a floor and ceiling, where they kept hay tools, provisions, honey from the boards. Here, according to the old people of this village, for ten years before the founding of the plant, at times they began to hear a rumble, as if from a ringing of a bell, which had never happened before. Then the Votyaks began to explain that there would once be a Christian church here and crush their sanctuaries, where it was so convenient for them to offer sacrifices to Keremet" (VEV , 1863, No. 2, p. 588)

The symbol of the city, directly related to the history of the plant.

Just a discovery for myself, dug up on the Votkinsk website:

“The first monument on the territory of Udmurtia, reflecting factory production, was a 167-pound anchor, made at the Votkinsk plant in 1837 for the Black Sea Admiralty. The heir to the All-Russian Throne, Grand Duke Alexander Nikolaevich (future Emperor Alexander II), took part in the forging of the anchor, as evidenced by the inscription carved between the paws of the anchor: “His Imperial Highness the Sovereign, Heir to the All-Russian Throne, Grand Duke Alexander Nikolaevich honored to forge with his own hands an anchor weighing 167 pounds . May 22, 1837". On the other side of the anchor was carved the inscription: "Delan under the head of the mining lieutenant colonel Tchaikovsky, the manager of the plant, Major Romanov and the commission agent of the Admiralty Department Alekseev."

It was decided to leave the anchor at the Votkinsk plant as a monument. The project of the monument was carried out by the manager of the plant V.I. Romanov. The monument was solemnly opened on June 16, 1840. His Grace Neophyte, Bishop of Vyatka and Slobodskoy, having performed a prayer service with the cathedral of the clergy, consecrated the monument.

"Monument" Anchor "". Picture. Author: Vasily Vasilyevich Nepryakhin. Paper, watercolor, ink. 1859 (1860?) In the lower right corner of the picture is the inscription: "July 25, 1859". On the back of the drawing there is an inscription in ink: "Drawed by the clerk Vasily Vasilich Nepryakhin."

"The anchor rested on a cast-iron pedestal, hung on a rod with chain ropes, surrounded by a very elegant lattice, divided into several parts by columns of the same cast-iron, on which double-headed eagles with spread wings sat. On two opposite sides of the pedestal, the following inscriptions from gilded letters read: "His Imperial Highness the Sovereign Tsesarevich, Heir to the All-Russian Throne, Grand Duke Alexander Nikolayevich honored to forge an anchor with his own hands at the Troitsk anchor factory when visiting his Kamsko-Votkinsky factory on May 22, 1837 "(extract from the Izvestiya of the Sarapul Zemstvo Museum. Issue 2. Sarapul. Printing house N.E. Onchukova, 1912).

The anchor, which was one of the main items in the nomenclature of forging products of the 19th century, served the Russian fleet for a long time and faithfully under Ushakov, Lazarev and Nakhimov.

62 percent of the total number of anchors manufactured in the 19th century at 24 Ural factories accounted for the Votkinsk plant. In terms of quality, Votkinsk anchors (produced at the Votkinsk plant by decree of Catherine II since 1779) were unmatched, they were supplied to the largest battleships of the domestic fleet. An outstanding naval commander, Admiral P.S. Nakhimov, who tested the anchors of the Votkinsk plant on the Black Sea in October 1847, noted that the anchors "turned out to be completely appropriate for their purpose."

In 1849, the Russian maritime department confirmed that the anchors made at the Votkinsk plant "deserved full approval and turned out to be the most excellent." Votkinsk anchors were honored to stand on pedestals in the years. Sochi and Votkinsk. The Maritime Museum of Klaipeda exhibits a 137-pound anchor, forged at the Votkinsk plant in 1803. During the years of Soviet power, the monument, to the creation of which the tsar himself had a hand, was melted down. However, on the occasion of the 200th anniversary of the Votkinsk plant, it was restored in the same place (a similar anchor can be seen on the territory of the plant itself).

The Votkinsk anchor today is not only a city insignia, but also a Russian one. Five years ago, a local exhibit passed a competitive selection in an international project, where the main symbols of our country were determined. Several museums from Udmurtia also took part in the competition, including our Museum of History and Culture. The Votkinsk museum workers, as an object from their funds that most closely matches the image of Russia, chose a drawing by the clerk Vasily Vasilyevich Nepryakhin "Monument" Anchor ", made in 1859, in the year of the 100th anniversary of the Votkinsk plant."

Monument of the Soviet era, Yubileiny Palace of Culture.

In almost every port city, an impressive anchor is permanently laid up as an attraction. These black giants radiate the calm power with which merchant and warships plied the sea. The largest anchor in the world is cast by special order and weighs 40 tons. Learn all about heavy and strong anchors, take a look at the photos of these secretive sea workers.

Heavyweight record holder

To build a strait crossing or an offshore oil rig, a floating crane capable of moving bridge spans is required. The vessel on which the floating crane is located must stand in place like a glove, otherwise it is impossible to ensure the accuracy of transshipment operations. The task of keeping it in place is entrusted to giant anchors.

In 1991, the Dutch company Ballast Nedam, specifically for the construction of the Great Belt Bridge in Denmark, ordered the Svanen cyclopean floating crane, the engineering features of which allow it to lift and move loads of over 8 million tons. How much does the anchor of such a structure weigh? As much as a modern tank or a humpback whale - 40 tons.

What do crane anchors look like?

These are constructions of a spindle and flat paws on spreading horns, unusual for illustrations in books about pirates. The anchors of floating cranes, especially those that mount bridge spans, look like hemispheres that can stick to the ground with hoses to remove water.

Similar suckers are put on floating cranes by another Dutch company - Balder. Its cranes have a lower lifting capacity - up to 3 million tons, but they work in conditions of strong currents and waves.

The memory of a sea giant

Among the outlandish exhibits in the courtyard of the Hong Kong Maritime Museum is the anchor of the supertanker Knock Nevis, picked up off the coast of India. The rusting titanium weighs 36 tons, is 10 meters long and is currently the first in the world in the Danforth class of designs with their flat knife-shaped paws. This anchor is one of the anchors - necessary to keep the ship out of the drift with the engines turned off.

Its dimensions are related to the dimensions of the tanker:

- length - 458 m;

- width - 69 m;

- stopping distance - 10 km;

- draft at full load - 30 m.

Knock Nevis was launched from the stocks in 1976, resold and rebuilt several times: either the vibration of the owners did not suit them, or the lack of a double side, or the inability to pass the Panama Canal. He spent the last 6 years of his life as a storage tanker, and in 2010 was scrapped. The gigantic anchor that held the giant in place is the only memory of this outstanding vessel.

What are aircraft carriers based on?

In 1982, the largest aircraft carrier in the history of shipbuilding was introduced into the US surface fleet with pathos befitting the moment. Unrivaled in size, crew size and investment, Carl Vinson also owns the corresponding dead anchors weighing 30 tons each.

They do not have stocks, but the swivel paws are securely buried in the ground and tightly retracted into the hawse when lifting. Engineer Frederick Boldt, who came up with such a solution back in 1898, could not have imagined that floating air bases of the 21st century would use it. The American aircraft carriers Saratoga and Forrestal, the French oil tanker Batillus are ships whose anchors designed by Boldt weigh from 27 to 30 tons.

Champions of the Russian fleet

In Nikolaevsk-on-Amur, an old wrought iron Tsar-anchor weighing 6.1 tons is available for public viewing. Its length from eye to heel is 4.8 m.

And in 2012, during the reconstruction of a shipyard in Vladivostok, a six-ton colossus was discovered from those that were installed on battleships during the Russo-Japanese War. Its length is 6 m, and its paw span is 4 m.

Flipper delta - Boldt's rival

The Dutch inventor Peter Claren in 1975 proposed to reinforce the anchor with three triangular planes, which gave the structure the appearance of a hang glider.

The idea turned out to be successful, and the company that produced the novelty sold products with a total weight of 0.5 million tons in the first year. Flipper Delta weighing 27.2 tons to this day holds floating cranes, and smaller models are supplied by sea rescue tugs.

Dead anchors - no equal in strength

When developing oil wells in the Gulf of Mexico, engineers were faced with the problem of silty soils: anchors in them did not hold pontoons. In the 50s of the last century, three new solutions were proposed at once, united by the name "dead anchors". They are small, within a ton of weight, but are able to hold a drill projectile.

Dead anchors: with a reinforced paw (left) and a kite (right)

Dead anchors: with a reinforced paw (left) and a kite (right) The model called "kite" is especially strong. It plunges into the silt to a depth of 10-15 m. True, it is impossible to pull it out of there. Given the low cost, it is simply left in the ground.

How to hold 4 ships at the same time

In 1848, the English engineer Mitchell came up with a brilliant idea: he came up with an anchor that is screwed into the bottom soil with a lever. Guided by this idea, the Newcastle Port Authority built a number of mooring barrels in the roadstead, each of which was held on one anchor-screw and received 4 ships.

The next storm scattered the ships in other ports, and in Newcastle the captains found the ships where they had been left. Floating port facilities, such as lighthouses, are still placed on screw anchors.

New operating principle

Calculations show that with a hurricane wind, even an anchor weighing 90-100 tons will not hold an oil tanker 400 meters long. And if there are corals under the keel, the paws of the anchor will completely slide helplessly over them. The solution was proposed by American military engineers. Their jet anchor weighs 6.8 tons, yet has such holding power as if it weighed 19 tons. It is equipped with a rocket that explodes when it hits the ground and deepens the anchor by 8-10 m. In order for the tanker to resume movement, the anchor chain is opened, because it is unrealistic to pull the jet model out of the ground.

Unsurpassed in area

It is easy to gain a foothold near the shore, but what if a small ship is caught in bad weather on the high seas? The main task of the captain is to keep the watercraft bow to the wave, and the assistant for this is a floating anchor, which is thrown from the bow. This is a canvas cone with a metal cross at the base. The structure looks like an elongated parachute, an umbrella or a trawl for bottom fishing. The diameter of the inlet of the cone is half the width of the vessel. The outlet is 10 cm, which creates a decent resistance force.

To increase the strength of floating anchors, ballast is suspended from below, and a buoy is attached from above. Together, the ballast and buoy hold the anchor at the correct depth.

The history of anchors begins from the time when for the first time a heavy stone was tied to a vine and thrown to the bottom. Since then, these devices have become more convenient and heavier. However, at 40 tons, gigantomania ended. Screws, suction cups, jet devices are replacing the usual wide-legged giants that adorn the squares of cities of ship glory.

For thousands of years, the anchor has been and remains an integral part of every ship. With the exception of the biblical ark and the legendary Flying Dutchman, we are unlikely to find a ship without an anchor. In our time, the absence of even a safe anchor, not to mention those that are supposed to be in hawse, according to international rules, does not give the ship the right to go to sea. We are so used to this word that we don’t even think about its origin. Whether it was born in the depths of our language or was it borrowed! The opinion of the readers of our magazine on this issue differs. We think that it will be interesting for readers to get acquainted with two points of view on the origin of the term "anchor" in Russian.

Here is what the marine painter L. Skryagin claims in his book "Anchors".

ANCHOR, WHICH itself, when pulled by a rope, turns over onto a horn, was invented in the East 2 thousand years BC. e. Such anchors, first made entirely of wood, and later with lead rods, became widespread in the Mediterranean basin. But who was the first to make them out of iron?

The ancient Greek writer Pausanias (II century) claims that the first two-horned iron anchor was forged by the Phrygian king Midas (VII century BC). The Greek poet and musician Arian (7th century BC) says that in the temple of the goddess Phase he saw the stone and iron anchors of the Greeks. The Roman writer Pliny the Younger (62-114) considers the Greek Eulampius the designer of the iron anchor, and he attributed the invention of the iron anchor, the horns of which had paws at the ends, to the ancient inhabitants of Etruria. The famous Greek geographer and historian Strabo (64 BC) reports that the inventor of the first iron anchor with a stock was a Greek scientist, a Scythian by origin, Anacharsis, who in the second half of the 7th century. BC he moved to Greece. Historian Polydor Virgil Urbinsky in his book “Of Books on the Inventors of Things” (Moscow, 1720) writes: “The anchor was invented by the people of Turin. Evlampy also made a two-horned anchor. The well-known English historian of shipbuilding, a sailor by profession and an outstanding poet, William Falconer, in his Nautical Dictionary, published in London in 1769, considers both Eulampius and Anacharsis to be the inventors of the iron two-horned anchor.

As you can see, the opinions of historians differ. However, one thing can be said: the iron anchor appeared somewhere in the 7th century. BC e., most likely in the second half of it. The Greek Eulampius, the Scythian Anacharsis, and King Midas of Phrygia could have been its inventor. The place of appearance of the first iron anchor can be considered the basin of the Mediterranean Sea, where it quickly spread among the sea peoples who lived on its shores. Recall that the role of this sea for ancient civilizations was exceptionally great. And of paramount importance for the ancient cities, which, according to the figurative expression of Cicero, “are located around the Mediterranean Sea, like frogs around a pond,” were maritime trade and shipbuilding associated with it. That is why the spread of the iron anchor, the development and improvement of its design took place in this basin - the cradle of Western shipbuilding and navigation.

The iron anchor became the main product of the first blacksmiths, along with the plowshare, sword, and axe.

The very word "anchor" can rightfully be considered international. Here is how it is spelled and pronounced in several modern European languages: Italian - an coga (anchor); French - an sge (anker); English - anchor (anchor); Spanish - ancla (ancla); German - anker (anchor); Norwegian - anker; Danish - anker; Swedish - ankare (ankar); Dutch - anker (anchor); Finnish - ankkuri (ankuri).

A very similar spelling and sounding of this word is striking, the common root “ank” is felt. Philologists attribute the word "anchor" to the number of words borrowed by these languages from ancient Greek or Latin, which once again confirms that the birthplace of the iron anchor is the Mediterranean basin.

The ancient Greeks called the iron anchor the word "ankur a" - "ankura", derived from the root "ank", which in Russian means "hook", "curved" or "curved". Thus, the word "ankura" can be translated into Russian as "having a curvature" or "having a curvature." Who knows, maybe the first iron anchors really looked like big hooks!

From the ancient Greek "ankura" the Latin word "anchora" was formed, which later passed to other languages \u200b\u200bof Ancient Europe. The English language of the Anglo-Saxon period borrowed the word "an cor" directly from ancient Greek. And in the ancient German language there is the word "anch ag", the spelling of which indicates its belonging to the Latin language.

In the Russian language, the word "anchor" migrated from ancient Greek. In the Old Russian language, the Greek form "ankura" is found, which later turned into "anchor".

The well-known Russian linguist I. I. Sreznevsky in his book “Thoughts on the History of the Russian Language” says that the term “anchor” is considered to be transferred to us by the Varangians, but it could also be borrowed from the Lithuanians, “who were forged by the gods themselves“ encurls ”. Serbs and Croats have the word "jekap".

In writing, the word "anchor" is first mentioned in Russian in the annals of Nestor "The Tale of Bygone Years"- in the oldest of the written monuments of the history of our Motherland that have come down to us. It says that under the terms of the peace treaty dictated by Oleg to the Greeks in 907, the Russians, among other tributes, were to receive flour food, anchors, tackle and sails for their fleet. In the annals of Nestor, it sounds like this: "... yes, they eat ... brashno and anchors and snakes and sails."

The word "anchor" has long been used in old Russian Pomor proverbs and sayings: “Faith is my anchor”, “The language of the body is an anchor”, “Wherever the boat roars, but the anchor will be” etc. This word is also found in many Russian epics. So, for example, in one of them, about Vasily Buslaev:

"And they cast strong anchors,

From the bow - anchor,

From the stern - another.

To stand stronger.

He didn't stagger."

"Great diligence and extreme art"

"Salt, hemp and wax" - we remember these words from school. This is an uncomplicated list of goods that Ancient Russia traded. Later, bread, timber, furs and flax were added to them. We are so accustomed to considering old Russia an agrarian power that we are sometimes surprised: really, long before Peter I, Russia exported iron to the foreign market, and iron, which was famous throughout Europe? It was taken in strips and in the form of products: axes, plowshares, etc. The anchors included in this list, made of "swamp iron", were famous in the same way as Russian sables. An unacceptable mistake is made by those historians who believe that, they say, metallurgy in our country began to develop since the time of Peter. The Russians knew how to make iron long before him, and as for iron anchors, they were undoubtedly forged even before the baptism of Russia. This is evidenced by many exhibits collected by local historians, folk epics tell. The emergence of anchor production in Russia is lost in the mists of time.

Yaroslavl, Vologda, Kazan, Gorodets, Voronezh, Lodeynoye Pole, and many cities of the Urals were once famous for their anchor masters. For example, the anchor craftsmen of Yaroslavl and Vologda forged about a hundred "large two-horned anchors" for the ships of the sea flotilla, built on the orders of Boris Godunov.

It is sometimes believed that at one time Tula was famous for anchors. This is mistake. In Tula, they never forged anchors. She is famous for thinner and more elegant forgings. In 1667, when Russia was building its first large ship to sail along the Volga and the Caspian Sea, the Tula craftsmen refused to forge anchors for it. Blacksmiths in the village of Dedinovo, where the Eagle, a three-masted sailboat 24.5 m long, was built, also stated that they themselves did not know how to do this, and the only anchor master in the village was busy making a tongue for the Big Assumption Bell. Blacksmiths called from Kolomna also did not agree to forge anchors, and the craftsmen had to be sent from Kazan. It was they who made two large anchors with rods and four cat anchors for the Orel.

Even before Peter the Great, anchor production was widely developed on the banks of the Volga. For centuries, this craft flourished in the Nizhny Novgorod province.

From the travel notes of the Russian academicians of painting G. G. and N. G. Chernetsov, who in the middle of the last century traveled along the great Russian river, we learn that anchors were made mainly in Gorodets:

“Gorodets used to be a city and residence of the princes of Gorodetsky and even had its own bishops. Now it is only a significant village. Forging anchors and bell tongues is a significant craft of the inhabitants.

Anchors are made weighing from thirty pounds to eighty pounds. In Gorodets with the surrounding villages, up to twenty thousand pounds of anchors are forged during the year.

The domestic shipbuilding that unfolded under Peter I, as a result of which Russia received 895 ships, led to the rapid development of blacksmithing. Peter personally established strict rules for testing the iron produced in the country. And soon Russian metal had no equal in quality all over the world.

Anchors for - the ships of the Azov fleet, built by Peter in Voronezh, were forged by blacksmiths gathered from all over Russia. By a special decree, Peter forbade them to forge any products other than those related to the fleet, and ordered the monasteries to pay for their work. The blacksmiths of the first Russian breeders - Demidov, Butenat, Naryshkin, Borin and Aristov - also had to supply anchors. Later, "state-owned iron factories" were established in the Novgorod and Tambov provinces, and exploration work began to identify iron ore deposits near Lake Ladoga.

Anchors for the first frigates of the Peter's fleet, which were built in 1702 on the Svir and Pasha rivers, were forged in Olonets (Lodeynoye Pole). In 1718, part of the anchor forge from Olonets was transferred to Ladoga, and from there in 1724 to Sestroretsk.

During underwater archaeological research 1971 - 1975. on the island of Khortytsya, in addition to many sunken ships, cannons and cannonballs, they found about 30 four-legged cats and Admiralty anchors with inscriptions and stamps indicating that they were made in 1722-1727. Wooden anchor rods were not preserved, but square yokes were found nearby.

In the hallmarks on two Admiralty-type anchors and one with four legs, the word “LADOGA” is repeated, indicating that some of the anchors for the Dnieper flotilla were manufactured at one of the first Russian shipyards on Lake Ladoga.

The iron obtained from the Olonets "bog ore" was valued in Europe on a par with the famous "Swedish iron" and was famous for its flexibility, good malleability and extreme toughness. In addition, it was easily welded: the clean surfaces of two pieces of iron, heated to the appearance of sparks, were combined into one mass from a hammer blow or strong pressure. And this property is important. Here is a good example. Anchors for the ships of both Kamchatka expeditions of Bering-Chirikov (1725-1743) had to be carried across Siberia on deer. Since such a load turned out to be beyond the strength of a fragile animal, the horns were beaten off from the anchors ready for shipment. Parts of the anchor were transported through Siberia separately and already on the Pacific coast, in temporary forges, the horns were again welded to the spindle. Wooden rods were made, of course, from improvised materials on the spot.

Such anchors made of "swamp iron" were many times stronger than the English ones, because in Russia charcoal was placed in the furnace to make iron, and puddling furnaces were heated with firewood. In England, for the manufacture of iron in the furnace, coal and coke containing sulfur and phosphorus were used, which reduced the quality of iron. The Russian two-weld iron used for the manufacture of anchors was superior in quality to the English three-weld iron. Under the blows of the hammer, the "swamp iron" was well riveted, and with the next heating - annealing, its former softness was easily restored. The fact that Russian anchors were in great demand abroad can be judged from many documents of the time of Peter the Great. Here, for example, is a letter from the Russian ambassador to Denmark, Vasily Dolgorukov, to Peter I dated March 8, 1718:

“... There are ship anchors here in Your Majesty's shops, with which the painting is enclosed; there are also cannons and buckshot. And since I don’t have a decree to sell it, I’ll order to put buckshot and anchors as much as possible on the Yegudiel ship, and send it to St. Petersburg, and I’ll wait for Your Majesty’s decree in the rest. The naval commissioners of His Majesty, the King of Denmark traded those anchors with me and told me that they had such a need for them that several ships would not be able to go to sea for them. I refused to sell them and said that without a decree I dare not ... ".

In the last years of the reign of Peter I, ten state factories worked for the needs of the fleet: in the north of the country - Olonets, Petrovsky (the cities of Beloozero and Kargopol, which were previously under the jurisdiction of the Olonets shipyard), Izhora, Konchezersky, Ustrets, Povenets and Tyrnitsky were assigned to it; in the south - Lipetsk, Kozminsky and Borinsky. In 1722, some of these factories were sold to private entrepreneurs.

The heaviest anchors for large ships of the Russian fleet were then made in Izhora, where in 1719, by decree of Peter the Great, the Admiralty Plants were founded. Forging hammers at these factories were driven by water mills.

The high demands Peter made on the quality of the material going to the anchors can be judged by his decree “On testing at iron factories”, sent out in April 1722 by the Bergcollegium “to all iron factories where iron is made”. In fact, this is a law on mandatory rules for testing and subsequent branding of iron. The first test of strip iron, invented by the king, consisted in the fact that an iron strip was wound around a pillar six inches in diameter dug into the ground. This operation was repeated three times (in different directions), after which the strip was inspected, and if it did not show signs of destruction, stamp No. 1 was stamped on it. If the iron survived, stamp No. 2 was stamped on it. On strips that did not withstand either the first or second test, they put stamp No. 3. Sale of strip iron without these stamps was prohibited.

To oversee the blacksmiths, Peter established a position - "commissar over iron work." Peter's decree on the testing of iron, despite the primitiveness of the samples, marked the beginning of the struggle for the quality of the metal on a national scale.

Other decrees of Peter associated with anchor production have also been preserved. One of them, dated January 17, 1719, reads in part:

“... send good two people from the anchor foremen, one to the lower Gorodets volost, where there is a large anchor factory, the other to Tikhvin as a master, and with them one blacksmith, and give them a spot with such a decree that no one will have any anchors I sold without their spots, and so that they founded this business in both places.

Peter himself was a good blacksmith. Arriving to inspect the Istets factories, he forged eighteen poods of iron with his own hands in a day. He always treated blacksmiths with great attention and care. For example, when he learned that Maxim Artemiev and his apprentice Gavrila Nikiforov were considered the best anchor craftsmen in the Nizhny Novgorod province, he immediately issued an order to transfer both to the Voronezh shipyard. The first was appointed an anchor master with an annual salary of 12 rubles, and the second - as an apprentice with a salary of 10 rubles. At that time it was a lot of money. In addition, they still received "daily and fodder", that is, in modern language - "per diem". And when the construction of the Azov Fleet was completed, they were first sent “to anchor business” to the private iron factories of Butenat, and from 1706 they forged wonderful anchors at the Petrovsky factory.

On the technology of manufacturing anchors in Russia at the beginning of the 18th century. we learn from the “Regulations on the management of the Admiralty and the shipyard”, issued by Peter on April 15, 1722: “Anchors must be made according to the prescribed proportion of good iron, and look firmly so that the rods are firmly and tightly connected with good iron before they begin to lay into the mountain." When heated in the hearth, it was instructed to carefully ensure that the metal "neither burnt nor coldly removed, so that it would be tightly welded everywhere and there would be no lack of brewing." The same conditions had to be observed both “in welding the horns to the spindle”, and during “beating on the anvil”.

From the anchor master, Peter demanded not just “to manage the work with diligence and good skill,” as from other blacksmiths, but “great diligence and extreme art.” Anchor craftsmanship was especially reminded that it was he who should answer if the ship’s accident occurred due to anchor breakage: “Because the whole integrity of the ship consists in what he should give an answer if that is done by negligence.”

Under Peter, anchors were subjected to a severe test of strength. The new anchor was first raised to the height of the spindle and thrown with the heel onto the cast-iron beam, then, raising the anchor to the same height, it was again thrown down with the eye and, finally, sideways, in the middle of the spindle, on the gun barrel. If the anchor withstood these three throws, a special mark was stamped on it. Such a test of anchors by throwing became traditional in Russia and remained almost until the end of the last century. Here is how it was carried out in the thirties of the last century at the Ural factories:

“... Anchors to touch it by the ring that has a forearm with a rope and thread that rope into the block that was made for the iron described above, and lifting it up to the very block, lower it, without holding it, onto a cast-iron bar or board three times. And if it resists, then incise on it the master, where it is made, and the number of the present year and his master and managerial, who, with one sample of the incident, name and weight and the letter “P”, which means that it has been tested, and give it by notch to the treasury with a note. And those samples that do not stand, but show a break or a gap, do not accept such, but order them to be corrected, and after correcting the packs, try against the above and, according to the sample, give it to the treasury. And for the time that they will stay during the correction, do not give anything for the work, because they are guilty of doing it regularly from one time.

The above excerpt is from the chapter “The Case of Anchors, Hammers, Clamps and Other Things” of the book “Description of the Ural and Siberian Plants”. The author of this book is Georg Wilhelm de Gennin (1676-1750), a Dutchman from Amsterdam who has been in the Russian service since 1698. He was an outstanding engineer and metallurgist of his time. He managed the Ural factories for twelve years and was one of the best experts in the mining and metallurgical business of the 18th century. No wonder Academician M.A. Pavlov once called this book an encyclopedia of mining and metallurgy in Russia.

Peter introduced cruel punishments for branding anchors without a strength test. From the list of sentences carried out and decisions of the Admiralty Collegium for Judicial Cases dated 1723, we find the following:

“The anchor foreman and blacksmith for branding anchors without a test are supposed to declare death and hang on the gallows, but not to execute, but on punishment with a whip send to the Astrakhan Admiralty to work for 5 years, in which they will always be chained.”

In Russia, since the time of Peter the Great, every ship of the line has been supplied with five anchors.

What was the form of Russian anchors in the Petrine era and later?

In the domestic practice of shipbuilding of that time, Dutch methods prevailed, and Peter ordered the anchors to be “made according to the Dutch drawing”, that is, with horns curved in the form of an arc of a circle. Six such anchors (their wooden stocks have not been preserved) can be seen in the estate-museum of Peter I "Botik" in Pereyaslavl-Zalessky. They belong to the period of the “amusing fleet” (1691-1692), when the Dutch built the first ships for Peter under the supervision of the craftsmen Kort and Klass.

On fig. 70 is a drawing of a Russian anchor of the Dutch type from the beginning of the 18th century. It was built by the chief custodian of the ship fund of the Central Naval Museum, A.L. Larionov, as a result of a thorough study of the proportions and drawings of anchors given in the old books of Dutch shipbuilders of the 18th century, and six remaining anchors in Pereyaslavl-Zalessky. In his study, A. L. Larionov determined a number of proportions of individual parts of Russian anchors of the early 18th century. For example, the thickness of the spindle in the anchor collar was set as follows: the number of inches equal to the number of feet in the length of the spindle was subtracted from the length of the spindle, and the resulting remainder was divided in half, which gave the number of inches of the spindle section in the anchor collar. The length of the anchor was equal to 2/5 of the width of the ship with sheathing, the sheym was 2/13 of the length of the spindle, the eye was equal to 1/6 of the length of the spindle, the section of the eye was equal to 73 of the diameter of the spindle, the arc length of both horns was 7/8 of the length of the spindle, the length of the rod was equal to the length spindles with an eye, the ratio of the length of the paw to its thickness was 4:5.

In addition to the Dutch-style anchors, under Peter I, other anchors were made in Russia. It is known that ten years before his death, Peter began to replace the Dutch shipbuilders who worked in Russian shipyards with English ones. That is why in Russia the "anchors of the English drawing" - with straight horns - have become widespread. They were forged in Russia along with the Dutch from the 20s. 18th century One of these anchors, made in 1722, was found in 1975 on the Dnieper island of Khortitsa.

70. Scheme of the Russian anchor of the Dutch sample of the Petrine era.

By the middle of the XVIII century. the production of anchors in Russia has reached its perfection. By this time, we had developed our own national type of anchor, different in its proportions from the anchors of the Dutch, British and French.

Over the past 15-20 years, in different seas washing the shores of our country, many interesting underwater archaeological finds of ancient anchors have been made. Of these, about ten belong to the period 1720-1773. Interestingly, all these anchors have the same characteristic "pattern" (Fig. 71). Apart from slight differences in their details, they are almost similar in their proportions. Moreover, these proportions appear in the old Russian manuals on shipbuilding and in maritime practices (Kurganov, Gamaleya, Glotov, etc.).

71. This is how Russian anchors looked from the middle of the 18th century to the beginning of the second half of the 19th century.

spindle length - 3/8 of the ship's width with sheathing;

the length of the horn is 3/8 of the length of the spindle;

paw length - 1/2 the length of the horn;

paw width - 2/5 of the length of the horn;

spindle circumference at the collar (trend) - 1/5 of the spindle length;

spindle circumference at the stem - 2/3 of the spindle circumference at the collar;

the thickness of the horns at the gate is equal to the thickness of the spindle at the gate;

the thickness of the horns near the paws is equal to the smaller diameter of the spindle;

the angle of the horn, made up with a spindle, is 56-60 °; sheima length - 1/6 of the length of the spindle; cross-section of the sheima - 1/20 of the length of the spindle; the length of the stem is equal to the length of the spindle (sometimes plus half the diameter of the eye);

72. Russian anchor 1761, found in 1968 in Kronstadt

stem thickness at shoulders - 1 foot of stem length gives 1 inch of stem thickness or 1/2 inch of stem length;

the thickness of the rod at the ends - 1 foot long gives 1/2 inch of thickness;

eye thickness - 1/2 the thickness of the spindle collar;

the diameter of the eye is equal to the length of the sheima (three diameters of the spindle at the collar).

The anchor built according to these proportions almost exactly corresponds to the original samples of Russian anchors of the 18th century, found in recent years in the Baltic and the Black Sea.

In 1968, during the repair of one of the piers in the Kronstadt harbor, four anchors weighing about three tons each were found. Now two of them are at the main entrance of the A. A. Grechko Naval Academy in Leningrad, and the other two (without stocks) have been transferred to the Central Naval Museum.

From the remaining letters of the inscription engraved on the anchor, it was only possible to understand that it was made in 1773 and weighs 169 pounds. On the second anchor you can read: “April 1761, 22 days. Weight 163 pounds 20 pounds. Delan ... master Kharitonov ... ". At what plant in Russia they were forged remains unknown (Fig. 72).

73. Russian names of parts of the anchor:

1 - spikes (shoulders, "nuts"); 2 - stock; 3 - ring (eye); 4- ear; 5 - sheima;

6 - yoke; 7 - spindle (forearm); 8 - paw; 9 - horn; 10 - heel;

11 - gate (forehead); 12 - blade; 13 - sock; 14 - mouse

A detailed measurement of these two anchors clearly showed the correctness of the above list of proportions of the Russian anchor of the 18th century. and allowed A. L. Larionov to recreate the methodology for constructing working drawings of domestic anchors of the second half of the 18th century. Since not a single working drawing of the anchor of the specified time has been preserved in our country, this was a great creative success of the chief custodian of the TsVMM ship fund.

Anchors with straight horns were forged in Russia and in the first quarter of the 19th century. They were replaced by simpler anchors with rounded horns and a spindle. We will talk about them later.

Over time, the number of anchors on Russian warships increased to ten, and each of them had a specific name, purpose and place on the ship. We find an accurate and clear description of them in the book "The Experience of Marine Practice", published in

1804 in St. Petersburg by Platon Gamaleya - "Captain-Commander, Inspector of the Naval Cadet Corps and member of the Imperial Academy of Sciences."

“They are on the bow: plecht and toy on the right side, daglix and bays on the left side. Of these, the one and the bays are placed near the tank on the sides, and are firmly attached to them with lashings; plecht and daglix are kept at the sides on pertulines and rustication, ready to throw them. Spare anchor mooring is placed in the hold in the main hatch; its spindle is lashed to a post supporting the cockpit beam, and its paws are buried in stone ballast; this anchor for its most convenient placement, does not have a stock with it, which is specially stored and attached to it when the need calls.

There are five small anchors, called verps, on the ship: the largest of them, called the stop anchor, is placed on the anchor of that one, and is lashed both to it and to the board; the other two lie in a similar way on the bay; the remaining two are placed on both sides on the latrine.

As soon as our further narration goes about the manufacturing technology of Russian anchors, we will remind the reader of the names of the main parts of the anchor (Fig. 73): spindle (handguard) 7, stem 2, horn 9, paw 8, blade 12, toe 13, mouse 14, collar ( forehead) 11, heel 10, sheima 5, spikes (shoulders, "nuts") 1, ear 4, ring (eye) 3, yoke 6.

These are the original Russian maritime names. They were used by both blacksmiths and sailors. True, at the end of the last century, such an “improved” name of the anchor part as “trend” (gate or forehead) got into Russian books on marine practice. This name came to our maritime language from English (trend - bend, bend).

"King Anchor"

As already mentioned, the production of anchors in Russia by the middle of the XVIII century. reached its perfection and by this time we had developed our own national type of anchor, different in its proportions from anchors made in other countries. The large Russian anchors that have survived to our time today delight us not only with the clarity of their pattern and the purity of the finish, but also with the amazing preservation of the metal. Many of them, having lain on the seabed for more than two centuries, have almost no traces of metal destruction from rusting, and some have preserved stamps and inscriptions. Of particular interest are the anchors with the hallmarks of the Ural factories, especially Votkinsk. The article “Description of the Votkinsk Plant”, published in the second (February) issue of the “Marine Collection” for 1858, says: “The production of anchors at the Votkinsk Plant was introduced almost from the very foundation of the plant and, improving year by year, has recently reached that degree of strength and purity, which rightly attracts the attention of connoisseurs of the case.

Now let's dwell on the methods and processes of making anchors in the Urals in the XVIII-XIX centuries.

After the death of Peter I, anchor production began to develop in the Urals - at the Botkinsky, Serebryansky and Nizhneturinsky factories. The first of them was founded in 1759 in the reign of Elizabeth by Count Shuvalov on the Votka River at the confluence of Berezovka and Sharkan. The abundance of forests, rivers and cheap labor provided the plant with rapid development, and it turned into one of the largest mining plants in Russia in the 18th century. The raw material for the manufacture of wrought iron - cast iron from the ore of Mount Blagodat - was delivered to the Votkinsk plant along the Chusovaya and Kama rivers, from the banks of which it was located 12 versts. For the production of anchors, the best puddled two-weld iron was used after careful selection and quality control.

Works on the manufacture of large anchors in the XVIII-XIX centuries. all over the world included the following processes: assembly of individual parts of the anchor from iron bars or plates, their welding in furnaces or furnaces, finishing under the hammer, footnote and finishing of the welded anchor. Before proceeding with the assembly of the parts of the anchor, a life-size drawing of it was made and patterns were made from it. All dimensions of the finished anchor had to exactly match these patterns. Until 1836, at all factories in the Urals, anchors were made according to the so-called "Russian method", and later - according to the methods of Pering and Parker. Egor Petrovich Kovalevsky, a mining engineer, a Russian progressive public figure and a brave explorer, became interested in the technology of manufacturing Ural anchors, which were famous for their strength. In the 30s. of the last century, being the bergeymester of the Ural gold mines, together with the engineer Noskov, he began to study the processes of production of anchors at the Goroblagodatsky factories. In the third book of the "Mining Journal" for 1838, his article "Anchor production in the Goroblagodatsky factories" was placed. In it, he compares Russian and English methods of making anchors.

Describing the whole process of making an anchor, E.P. Kovalevsky notes that according to the Russian method, its individual parts were assembled and welded from strip iron, while in England plates were first prepared from strips of iron, and parts of the anchor were already made from them.

According to the Russian method, the footnote of the anchor was carried out in four places, and according to the English - in five.

The reasoning of this mining specialist about the reasons for the poor quality of anchors is interesting. In the same article, he writes:

“The general property of any iron has a special influence on the fragility of anchors - to change its strength to a greater or lesser extent, both from individual and cumulative actions on it: heat and cooling, touching coal and forging, so that the best soft iron can in a product become brittle, if the final operation on it is not adapted to actually restore the softness it lost during processing. To achieve this, if possible, a completely ready anchor, as said, is heated and allowed to cool slowly.

If soft iron is subjected to too high a degree of heat, it may become granular and its particles will be coarser, the stronger the degree of heat and the thicker the anchor. If at the same time they cool down in this position without being constrained by forging, then they have a weak bond and make the iron brittle. But if at the same time such iron is forged, its parts take on their former form and softness is restored.

If iron is forged with considerable cooling, then its parts take on a flattened appearance and make the metal brittle in all its best qualities.

When iron during processing is often subjected to incandescence, then from the frequent contact of coal it can undergo carburization, become more carbonaceous (steelish) and, from the effect of cooling during forging, more or less brittle. Cementation with coal is more formed in the places of the anchor, which are incandescent adjacent to the place receiving pitch and not covered by the blast, which counteracts cementation.

Anchor places adjacent to footnote places, paws with a horn and horns with a forearm can get burned and become brittle. To the aversion of this, the demolished parts of the anchor are left thicker and finally rolled when finishing the entire anchor. In addition to the examples given, there are many cases that change the quality of iron in a surprising way, and it is obvious that in no product is the same iron subjected to changes so often in different cases as in the manufacture of anchors.

Having made a comparison of two methods of manufacturing anchors, E. P. Kovalevsky comes to the conclusion:

“Comparing both methods of making anchors, we see that the preparation of Russian anchors is incomparably simpler in every respect.

There are no such frequent weldings as with new demolished parts of the anchor, consequently, less waste of metal and fuel consumption, and less debt of day laborers. Therefore, Russian anchors are incomparably cheaper and can be prepared as soon as possible. These circumstances constitute a very important advantage of the old method. To confirm this with figures, it is enough to say that according to the Russian method, in each ready-made anchor, there is 71/2 pounds of iron per day or 12 working hours, and according to the English only 3 1/2 pounds.

According to the Russian method, 2 pounds of iron are used per pound of iron in the finished anchor, therefore, the waste of metal is 1 pound, and with new waste, 1 pound 34 pounds comes out.

To prepare a pood of iron at anchor according to the Russian method, one box of coal must be burned, and to prepare the same pood according to the English method, 2 boxes must be used. Consequently, at the same time, according to the Russian method, it is possible to prepare more than twice a pood of anchors compared to the English one, with a decrease in fumes and fuel consumption by almost half.

This interesting article ends with the following words:

“Mr. Guryev writes (Mining Journal, 1837, No. 5) that at the Royal Guerigny Factory in France, the preparation of anchors according to the English method has now been abandoned, because it was found that English anchors do not present any advantages over Swedish ones.

If the Swedish method used in France is the same as Rinmann and Gausmann describe it (from flashy blanks), then our method has a proven advantage over it ”(my detente. - L. S).

E. P. Kovalevsky proposed to the administration of the Goroblagodatsky plants a number of technological improvements, which further improved the quality of products and reduced their cost.

Until 1850, at the Votkinsk plant, the welding of all parts of the anchor was carried out in furnaces, but since that time they have been replaced by welding furnaces that were fired with wood. Around the same time, the Nesmith steam hammer of 4.5 tons appeared at the plant, which greatly simplified and improved the anchor manufacturing technology. In the middle of the last century, 250-350 people worked in the anchor shop of the Votkinsk plant, depending on orders for anchors. An artel of one master, one apprentice, two to five workers and one teenager worked on each fire of a forge or furnace in each shift, not counting the workers employed in the transport of coal. The plant produced anchors from small ones of 3-10 pounds to large ones of 250, 275, 300 or more pounds. The total mass of anchors made in one year reached 15,000 pounds.

The heaviest anchors of the Votkinsk plant weighed 336 pounds (almost 5.5 tons). The largest battleships of the Russian fleet were supplied with them, the best metal was taken for their forging, they were made by the best craftsmen, they withstood the most severe test that has ever existed in the history of metallurgy (Fig. 74).

To give the modern reader an idea of how much work it cost a hundred years ago to make an Admiralty anchor weighing 270 pounds for a battleship, we will cite an excerpt from an article by an engineer of the Votkinsk plant D. Leontiev. It was published more than a hundred years ago in the journal Marine Collection, No. 5, vol. XXVIII, 1865.

Here is how he describes the footnote of the anchor parts: “When the spindle and both horns are ready, proceed to the footnote.

The footnote of the spindle with horns is performed in one step. To do this, the ends of both horns and the spindle, which should be connected into one whole and make up the anchor gate, are laid in three welding furnaces. When all three parts have heated up to the proper var, they are taken out of the furnaces on cranes under a steam hammer and put on the anvil, first the caress of one horn, and on it the thorn of the spindle and then the caress of the other horn, while trying to bring all three parts into mutual agreement as accurately as possible. a position corresponding to the shape of the anchor, the upper horn being cut shorter than an inch by two, in so far as the hammer, striking it directly, lengthens it more than the lower horn. After that, they let the hammer go to the highest rise and rush to strike more often in order, as the blacksmiths say, to beat the var. When the master sees that the upper horn is well welded with the spindle spike, they stop the hammer fight and, raising the anchor, put an iron gasket under the caress of the lower horn and again start the hammer, which presses the tip of the lower horn against the gasket with blows and thereby promotes proper welding. After that, they start cutting off the excess metal in the collar and at the same time try to bring the horns with the spindle to their normal position, which could be disturbed during forging, and then the anchor is taken to the furnace for final finishing. Anchor bearing at 270 pounds lasts more than a quarter of an hour. Agree, you need to be able to conscientiously perform such an important and cumbersome work.

74. The shape of the horn and paw of the anchor of the Votkinsk plant in the middle of the 18th century.

The anchor that entered the forge is in an unenviable state: the place where the connection with the spindle (gate) followed, represents deep cracks, cavities or unnecessary elevations of metal; the horns are not in the same plane with the spindle, and their outer contour does not make up that part of the circle that should be formed with a radius equal to 0.37 of the length of the spindle. In addition to these inevitable shortcomings, it often turns out that both the spindle and the horns in the places adjacent to the gate have become much thinner as a result of the strong wars given to them before the removal of the anchor - in a word, they are burned. In order, in such a, one might say, miserable state of the future symbol of hope that came to the forge to give it both a fortress and a decent appearance, a lot of time, labor and costs are required; and, out of necessity, the tedious work begins.

First, the horns and the spindle are straightened, they are bent, pulled, twisted, twisted, and when, finally, these parts along their width are combined with each other in the same sectional plane and the extra contour of the horns, although only partially, will be introduced into the orbit of a normal curve, then, content with and with this, they begin to lay the slats, which achieves the goal of giving the anchor an appearance "...

This is how anchors were made a hundred years ago. Hell of a job! Such work really required "great diligence and extreme art," to use the words of Peter's Regulations. I. anchor masters of the Urals were virtuosos of their craft. Behind the dry, but precise presentation of the engineer D. Leontiev, one can feel all the tension of a very long and hard physical labor in smoky forges near puddling furnaces and furnaces full of heat. It can be boldly stated that in the range of forging products of the last century there is no thing that would be made with such diligence and attention as an anchor. Each anchor made in the Urals rightly deserves the name "Tsar Anchor", and each of the Ural anchors found is worthy of being placed on a pedestal in the most honorable place, as was done with the "Tsar Cannon" and "Tsar Bell" , although the first never fired, and the second never rang, while the anchors of the Urals served the glorious Russian fleet for a long time and faithfully under Ushakov, Lazarev and Nakhimov.

The forged anchor was subjected to several tests. The purity of the finish was checked by heating to a dark cherry color, when all the imperfections of the forging show through. Then he was thrown three times onto a cast-iron plate from a copra, lifting the first time to the length of the spindle, the second time to half the length of the spindle, and the third time to the length of the horn. The anchor that survived this test was thrown two more times with each side of the spindle onto a sharp cast-iron anvil. If he passed this test, he was hung up and beaten with seven-pound hammers. At the same time, a clear, sonorous sound testified that the forging was dense and there were no shells and cracks in it. If the anchor passed the test, a brand was stamped on it.

This should be considered in more detail.

The brand on the anchor is his face, so to speak, "passport". And if you know how to decipher it, then you can learn a lot about the anchor from the preserved brand.

Since the time of Peter the Great, there have been certain rules for branding anchors in Russia.

Here is an excerpt from one of them, taken from the file of the Central State Archive of the USSR Navy.

“The case of 1860 on the requirement of the Department of Mining and Salt Affairs to send naval officers to the Votkinsk plant to be present during the testing of anchors” (Sheet 251). “At the end of the test, when the anchor withstands it, marks are put on it: 1 - meaning the name of the plant; 2 - the name of the ruler; 3 - the name of the master; 4 - the name of the caretaker; 5 - name of commission agent, sample manufacturer; 6 - year of manufacture; 7 - the weight of the anchor in pounds.

From the Ural factories, the anchors that passed the test were sent to their place of service - to the Black Sea or the Baltic. Long was their way to the ship.

Ready-made anchors for Sevastopol were loaded onto row barges and floated down the Kama River, and then along the Volga to the village of Perevoloki. There, the anchors were reloaded from barges to shallow-draught barges, and barge haulers dragged them along the tributary of the Volga - the Kamyshinka River - to the source of the Ilovlya, which flows into the Don. Here winter set in, and anchors were carried along the first path on huge sledges for as much as fifty versts. In the spring, when the rivers opened up, the anchors fell into the Don basin, and only then into the Azov and Black Seas. In Sevastopol or Nikolaev, oak stocks were attached to them.

Now it was necessary to distribute the anchors among the ships. After all, one ship needs an anchor of one mass, and another - another.

In addition to various simple formulas of a purely empirical nature, which have already been described, in the middle of the last century, the Russian navy used a rule derived from comparing the mass of anchors with the dimensions of the ships of the Russian, English and French fleets. The length of the ship from the stem to the sternpost at the height of the gon-deck was multiplied by its greatest width with the skin, and the resulting product was divided by a certain number. It was: for three-deck ships - 40, two-deck - 41, frigates - 42, corvettes - 45, brigs - 50, tenders and schooners - 55, large transports - 45, medium and small transports - 50.

The resulting quotient showed the mass of the anchor in pounds. So, for example, the length of the three-deck battleship "The Twelve Apostles" - one of the largest battleships of the Russian fleet - along the gon deck was 211 feet and 9 inches, the width with the skin was 58 feet and 6 inches. The product was 12387.37. This number, divided by 40, showed the weight of the anchor in pounds - 310. The length of the ship "Rostislav" according to the race deck was 197 feet and 4 inches, the width with the sheathing was 57 feet. The product 11247, divided by 41, showed the weight of the anchor - 274 pounds.

In fact, on the ship "The Twelve Apostles" the anchors weighed from 283 to 330 pounds, and on the "Rostislav" - from 264 to 278 pounds. If the shipyard did not have an anchor calculated by weight, then it was allowed to take an anchor a few pounds more or less, namely: for anchors from 300 to 120 pounds, an increase of up to 9 pounds was allowed, and a decrease - up to 6 pounds. If the mass of the calculated anchor was less than 120 poods, then the actual mass of the anchor could be 6 poods less and 3 poods more than the calculated one. They were similar to those that currently decorate the Admiralty building in Leningrad from the side of the Neva. They are said to have been forged in 1863 by blacksmiths from the Nevsky Shipbuilding Plant for the battleships Admiral Spiridov, Admiral Chichagov and General-Admiral.

What is the mass of the largest Admiralty anchor made in Russia?

There is an opinion that the heaviest Admiralty anchors in Russia were made for the launching of the battlecruisers Borodino, Izmail, Kinburn and Navarin. These huge ships of that time with a displacement of 32,500 tons were launched (but unfinished) from the stocks of the Baltic Shipyard and the New Admiralty Plant in 1915-1916. Anchors, weighing almost ten tons, had wooden rods.

Considering the enormous difficulties associated with the manufacture of large anchors, it can be argued that the cost of "symbols of hope" a hundred years ago was prohibitive. For example, at the Votkinsk plant, a peck of anchor cost the treasury (with overhead costs) 4 rubles 99 kopecks.